The GuardLogix 5580 Integrates AI Directly into Industrial Control

Rockwell Automation presents a significant advancement with its GuardLogix 5580 controller. This device fuses traditional control logic with the ability to run artificial intelligence models natively, eliminating the need for external computers. It represents a shift in how factories can process information and make autonomous decisions. 🤖

Operation and Practical Use Cases

The system operates with pre-trained AI models that run on its robust industrial hardware. It analyzes complex data streams, such as vibrations, thermal patterns, and acoustic signatures, to identify deviations that precede a failure. This enables proactive maintenance scheduling. In assembly lines, it can integrate with cameras to inspect products and automatically reject those with defects, learning and adapting to operational patterns to reduce energy consumption. 🔍

Key System Applications:- Predictive Maintenance: Detects anomalies in machines to avoid unplanned downtime.

- Visual Quality Control: Inspects products with cameras and diverts defective parts without human intervention.

- Real-Time Optimization: Adjusts production parameters to improve quality and efficiency, learning from operating conditions.

The machine not only warns of problems but also learns from every adjustment, blurring the line between tool and intelligent colleague.

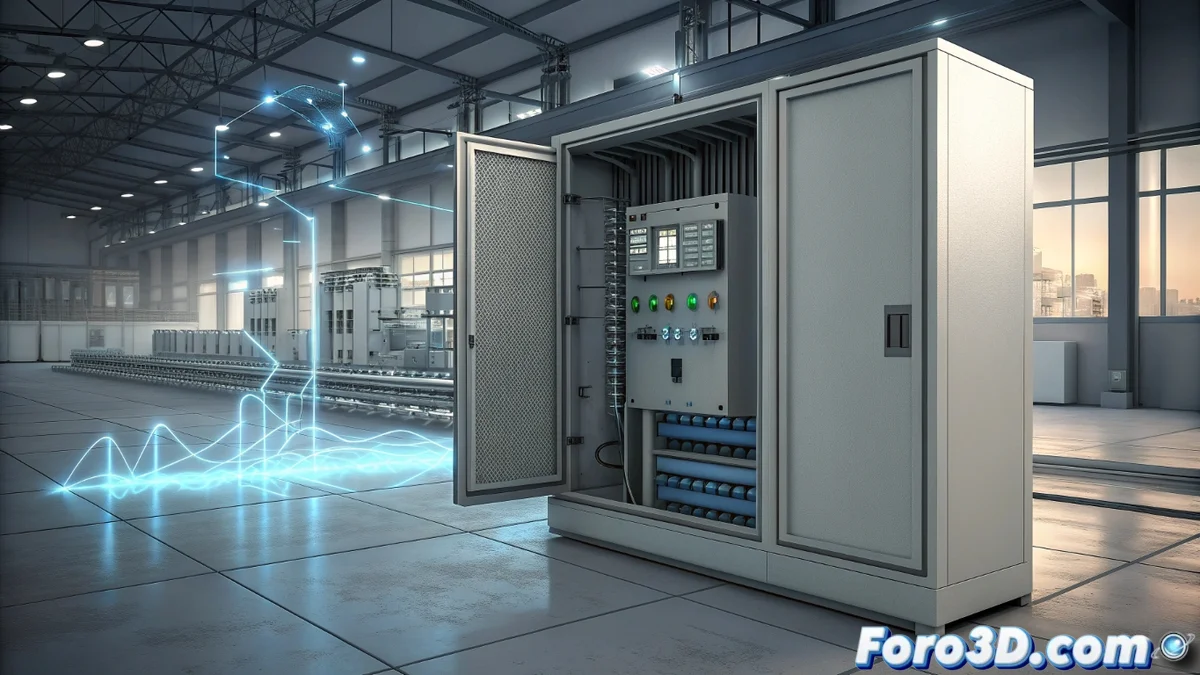

Technical Architecture and Safety Priority

Based on the ControlLogix platform, this PLC incorporates powerful processors to handle conventional control logic and AI workloads simultaneously. A fundamental pillar is its integrated functional safety, which complies with strict standards such as SIL 3 and Cat. 4 PL e. This ensures that critical safety functions, such as emergency stops, have absolute priority and integrity, even when AI algorithms are processing data. The architecture ensures that pursuing efficiency does not compromise personnel or plant protection. ⚙️

Architecture Elements:- Proven Platform: Inherits the reliability and robustness of the ControlLogix family for demanding industrial environments.

- Dual Processing: Manages real-time control tasks and AI data analysis on the same device.

- Certified Safety: Safety functions operate with a guaranteed integrity level, independent of AI operations.

The Future of Industrial Control

The GuardLogix 5580 marks a turning point by bringing autonomous decision-making to the controller level. It is no longer just about automating repetitive tasks, but endowing the machine with the ability to perceive, analyze, and optimize its own operation. This redefines the technician's role, who now interacts with a system that not only executes orders but also suggests improvements and prevents problems, making manufacturing more agile and resilient. 🚀