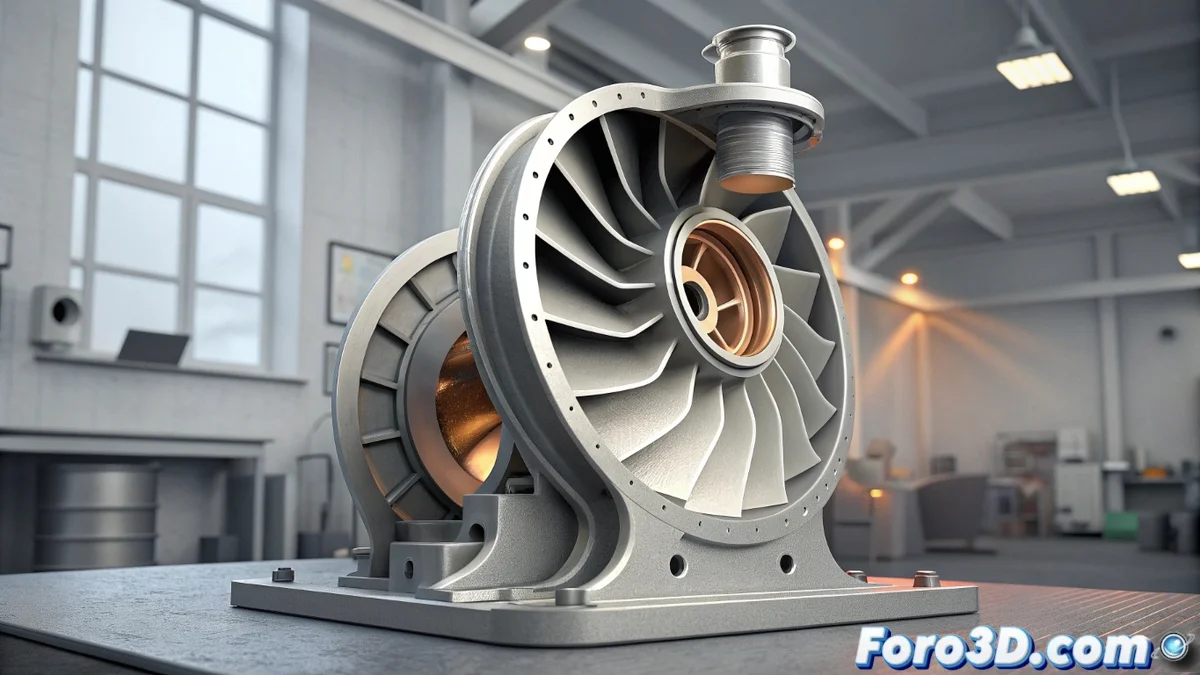

The E-2 Engine Turbopump is Entirely Manufactured Using 3D Printing

The company Launcher has taken a crucial step in aerospace engineering by producing the turbopump for its E-2 rocket engine using exclusively additive manufacturing technologies. This component is fundamental, as it is responsible for pumping the propellant at extremely high pressure into the combustion chamber. 🚀

Overcoming the Limits of Traditional Manufacturing

Conventional methods such as machining or casting impose severe restrictions on the shapes that can be achieved. 3D printing breaks these barriers by building the object layer by layer. This design freedom is key to optimizing the performance of critical parts.

Key Advantages of the Integral Design:- Eliminate Hundreds of Joints: The need to assemble flanges, welds, and bolts is eliminated, reducing potential weak points.

- Create Optimized Internal Flow Channels: Geometries with curves that minimize resistance and improve hydraulic efficiency are achieved.

- Perfect the Turbine: The blades and internal ducts can be designed to extract more energy from the drive gases.

Integrating multiple components into a single monolithic piece is not just a design advancement; it is a revolution in reliability and supply chain for the space industry.

Direct Impact on Weight and Development Timelines

The strategy of producing the turbopump as a single unit has tangible and highly valuable consequences for space missions. Every gram saved on the launcher translates into greater payload capacity.

Operational Benefits:- Drastic Mass Reduction: By eliminating joining elements, the final component is significantly lighter.

- Accelerate the Production Cycle: The total time to manufacture the unit is reduced from several months to just a few days.

- Facilitate Rapid Iterations: It allows testing and modifying designs with agility, speeding up engine development and testing phases.

A Technology Ready for the Most Demanding Environment

The E-2 engine serves as a demonstrator that metal 3D printing has reached the necessary maturity to operate in the extreme conditions of a space launch. This consolidates additive manufacturing not as a prototype, but as a reliable method for producing some of the most complex and critical components of a rocket. 🔥