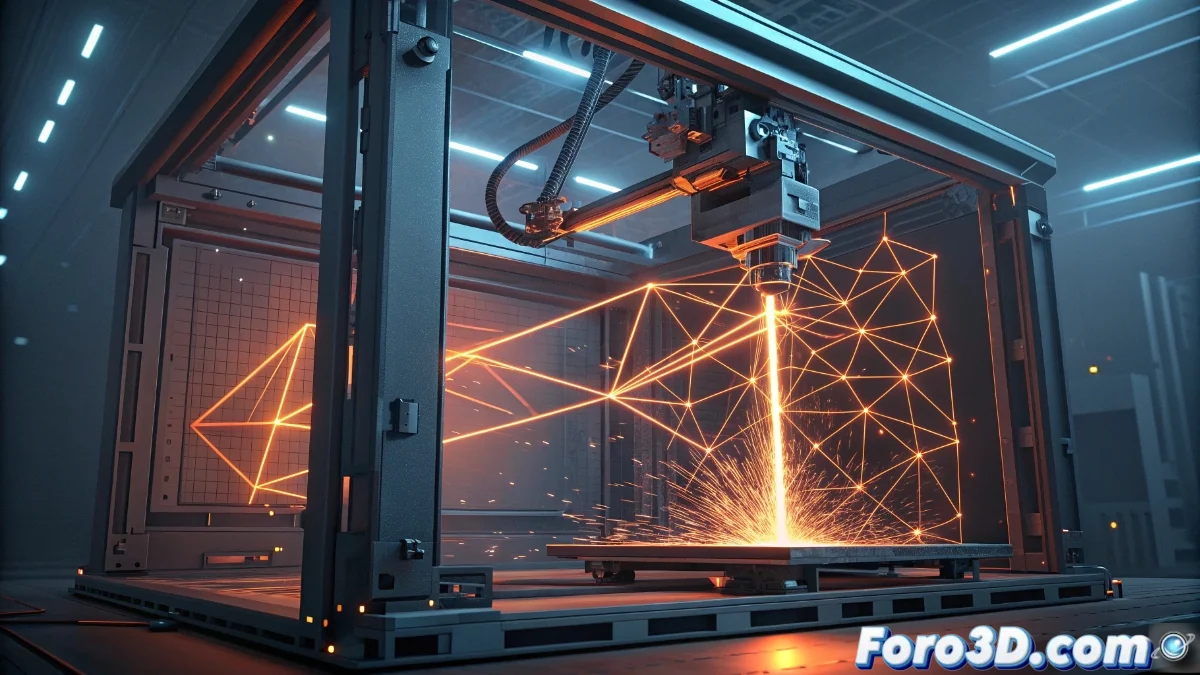

Dyndrite-EOS Collaboration Revolutionizes Additive Manufacturing with Vector Control

The strategic alliance between Dyndrite and EOS is marking a turning point in additive manufacturing by implementing vector path control that redefines the parameters of precision and efficiency. This technological synergy allows industrial 3D printing professionals to achieve unprecedented levels of optimization while maintaining exceptional quality standards in manufactured parts 🚀

Radical Increase in Operational Speed

Users report speed increases ranging from 200% to 300% compared to conventional methodologies. This quantum leap is due to Dyndrite's advanced geometric engine, which processes native CAD files without the need for intermediate conversions that traditionally slow down production flows. The generation of optimized toolpaths in real-time constitutes a transformative advance for applications demanding maximum productivity ⚡

Key Operational Advantages:- Direct processing of CAD data without redundant conversion stages

- Automatic generation of optimized toolpaths for each geometry

- Significant reduction in preparation and post-processing times

The ability to manipulate toolpaths at the vector level represents the greatest advance in print control since the introduction of industrial additive manufacturing

Cross-Industry Impact on Specialized Sectors

This innovation has critical applications in sectors where micrometric precision and consistent repeatability are fundamental requirements. Manufacturers in areas such as aerospace, medical, and automotive can now produce complex components with intricate internal geometries in radically reduced timeframes. The integrated platform operates with multiple material families, including metal alloys and engineering-grade polymers, expanding its utility across diverse 3D printing technologies 🏭

Priority Application Fields:- Aeronautical components with strict certification requirements

- Customized medical implants with complex anatomical geometries

- High-performance automotive parts with lightweight structures

The Immediate Future of Digital Manufacturing

It seems we finally have the technological capability to materialize those complex parts we so desperately needed... just in time for management to request multiple design iterations before project reviews. This evolution brings industrial additive manufacturing closer to its maximum potential, combining speed, precision, and flexibility in a unified ecosystem 🎯