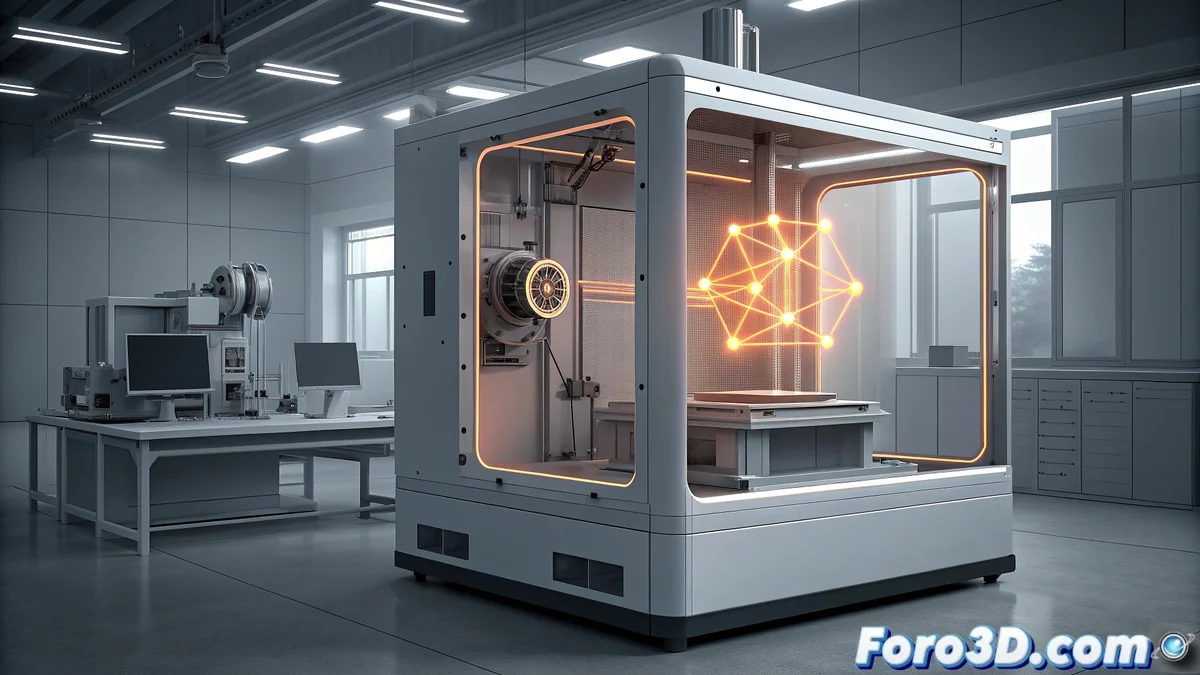

The Democratizing Revolution of SLS4All in Industrial 3D Printing

The selective laser sintering technology, historically the exclusive domain of large corporations due to its high costs and technical complexity, is undergoing a radical transformation with the arrival of SLS4All. This comprehensive platform is redefining the additive manufacturing landscape by making cutting-edge technology accessible to specialized workshops, innovative design studios, and forward-thinking small businesses 🔥

Innovative Technical Features of the System

The heart of SLS4All beats with an ultra-precise fiber laser that processes professional materials like nylon, polypropylene, and TPU, delivering components with mechanical strength equivalent to parts produced by injection molding. The build chamber maintains perfectly controlled thermal conditions throughout the entire production cycle, while the management software integrates automated tools for optimal orientation, support generation, and intelligent part packing 🎯

Key System Specifications:- Generous print volume that allows manufacturing multiple components in a single operational cycle

- Uniformly distributed temperatures throughout the build chamber for consistent results

- Intuitive software with automatic process optimization algorithms

"The irony that technology which previously required advanced specialization is now managed with an intuitive interface does not go unnoticed by industry veterans"

Practical Applications and Competitive Advantages

This revolutionary system unlocks potential in areas such as advanced functional prototyping, limited series manufacturing, and customized components for medical and dental sectors. Users can materialize complex and internal geometries that would be impossible with traditional manufacturing methods, permanently eliminating the need for expensive molds and intermediate processes 🚀

Main Fields of Application:- Functional prototyping with mechanical properties equivalent to final production

- Short series manufacturing with guaranteed dimensional repeatability between batches

- Customized medical and dental components with controlled porosity

Impact on Technological Accessibility

What was previously the exclusive territory of senior engineers with extensive experience is now within reach of university students with ambitious projects and independent professionals. The technological democratization represented by SLS4All marks a turning point in the additive manufacturing industry, where technical sophistication is no longer at odds with economic and operational accessibility ✨