Navigating Toward the Future with Metal and Data

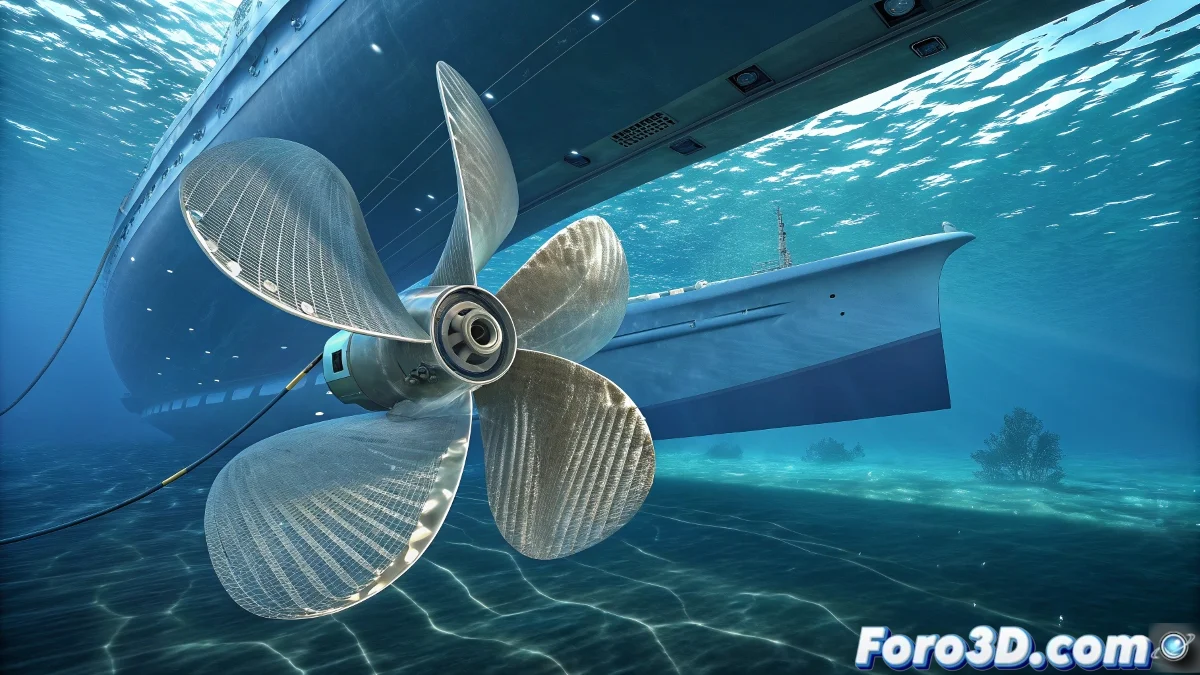

A UK consortium has launched the D.E.E.P project, an initiative that sounds like science fiction but is pure reality. Its mission is to transform a component as classic as the marine propeller, using additive manufacturing as the cornerstone. Imagine a propeller that is not just a simple cast piece of metal, but an intelligent device 🧠, capable of adjusting its behavior in real time according to the sea conditions, the ship's load, or the required energy efficiency. This is not a simple upgrade; it is a paradigm shift.

How a 21st-Century Propeller is Manufactured

The magic begins in the 3D printer. Additive manufacturing allows the creation of internal and external geometries that would be impossible with traditional casting techniques. We are no longer limited by simple shapes; now propellers can be designed with internal channels, alveolar structures to reduce weight, or surfaces with textures that optimize water flow. Rapid prototyping is another key advantage, allowing iteration and testing of designs in the blink of an eye, compared to slow conventional processes.

- Parametric and complex design: Freedom to create organic and highly efficient shapes.

- Total customization: Each propeller can be adapted for a specific type of vessel and mission.

- Sensor integration: The propeller itself can house sensors that monitor its performance and the environment.

Additive manufacturing not only changes how we make things, but what things we can imagine.

A Sea of Advantages and Some Potential Shipwrecks

The advantages of this approach are as clear as the water in a port on a calm day. Energy efficiency skyrockets, translating into monumental fuel savings and a drastic reduction in polluting emissions 💨. Additionally, it opens the door to a level of customization that was previously unthinkable. However, not everything is a bed of roses. The initial cost of advanced materials and the research itself is considerable. The big question hanging in the air is: will these printed propellers withstand the relentless corrosion and the force of the open sea? Validation of their long-term durability is the real challenge.

The Conclusion for Creative Minds

The D.E.E.P project is much more than an advance in naval engineering; it is a source of inspiration for any 3D design and digital manufacturing professional. It demonstrates how the union between generative design, smart materials, and 3D printing can solve complex real-world problems. This initiative not only aims to make ships more efficient, but redefines the limits of what is possible to manufacture. Perhaps soon, designing a simple propeller will be considered as archaic an art as carving a canoe from a log. 🚤