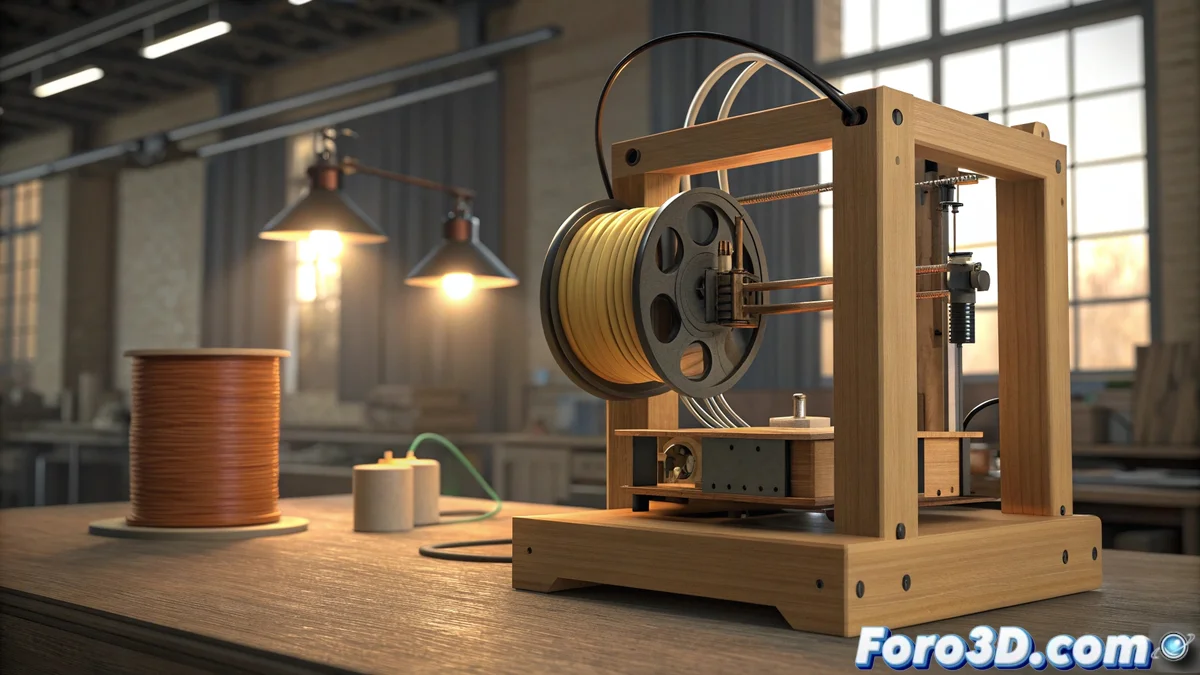

The Bamboo 0300-800A Printer and Its Revolutionary AI Monitoring System

The Bamboo printer with code 0300-800A represents a significant advancement in 3D printing technology by integrating an artificial intelligence monitoring system that automatically identifies excessive filament buildup during the manufacturing process. This innovative feature allows for the detection of potential issues in real time, preventing critical failures in parts and substantially improving operational efficiency. Users can fully trust that the equipment will respond agilely to any detected anomaly, minimizing both downtime and waste of valuable materials 🚀.

Operation of the Artificial Intelligence System

The mechanism employs advanced machine learning algorithms to continuously analyze the filament flow and compare it with normal operation patterns. When it identifies an unusual or atypical buildup, it immediately generates an alert that is transmitted to the user through the printer's integrated interface or via the connected mobile application. This capability not only effectively prevents dreaded clogs but also contributes to maintaining consistent print quality, as the AI system progressively learns from each session to refine its future detection capabilities.

Main features of intelligent monitoring:- Continuous analysis of filament flow using machine learning algorithms

- Automatic comparison with standard operation patterns

- Immediate notifications through multiple interfaces

"AI monitoring technology transforms the 3D printing experience, anticipating problems before they occur and optimizing every work session"

Practical Benefits for Users

Thanks to this cutting-edge technology, users experience significantly fewer unplanned interruptions and achieve substantial savings in material and preventive maintenance costs. The printer demonstrates remarkable adaptability to various types of filament and varying environmental conditions, positioning itself as an ideal solution for both beginners seeking simplicity and experts requiring precision. Additionally, the native integration with 3D modeling software facilitates a more cohesive workflow, where the equipment proactively communicates about possible optimizations and process improvements.

Differentiating advantages:- Drastic reduction in operational interruptions

- Optimization of costs in materials and maintenance

- Superior adaptability to different filaments and environments

Impact on User Experience

In practice, many users have stated that the printer seems to develop its own judgment, especially when alerting about problematic filament buildups that could go unnoticed by the human eye. This predictive capability not only safeguards the integrity of prints but also progressively educates the user on better practices and more efficient usage patterns. The machine thus becomes an intelligent ally that actively contributes to the success of every 3D printing project 💡.