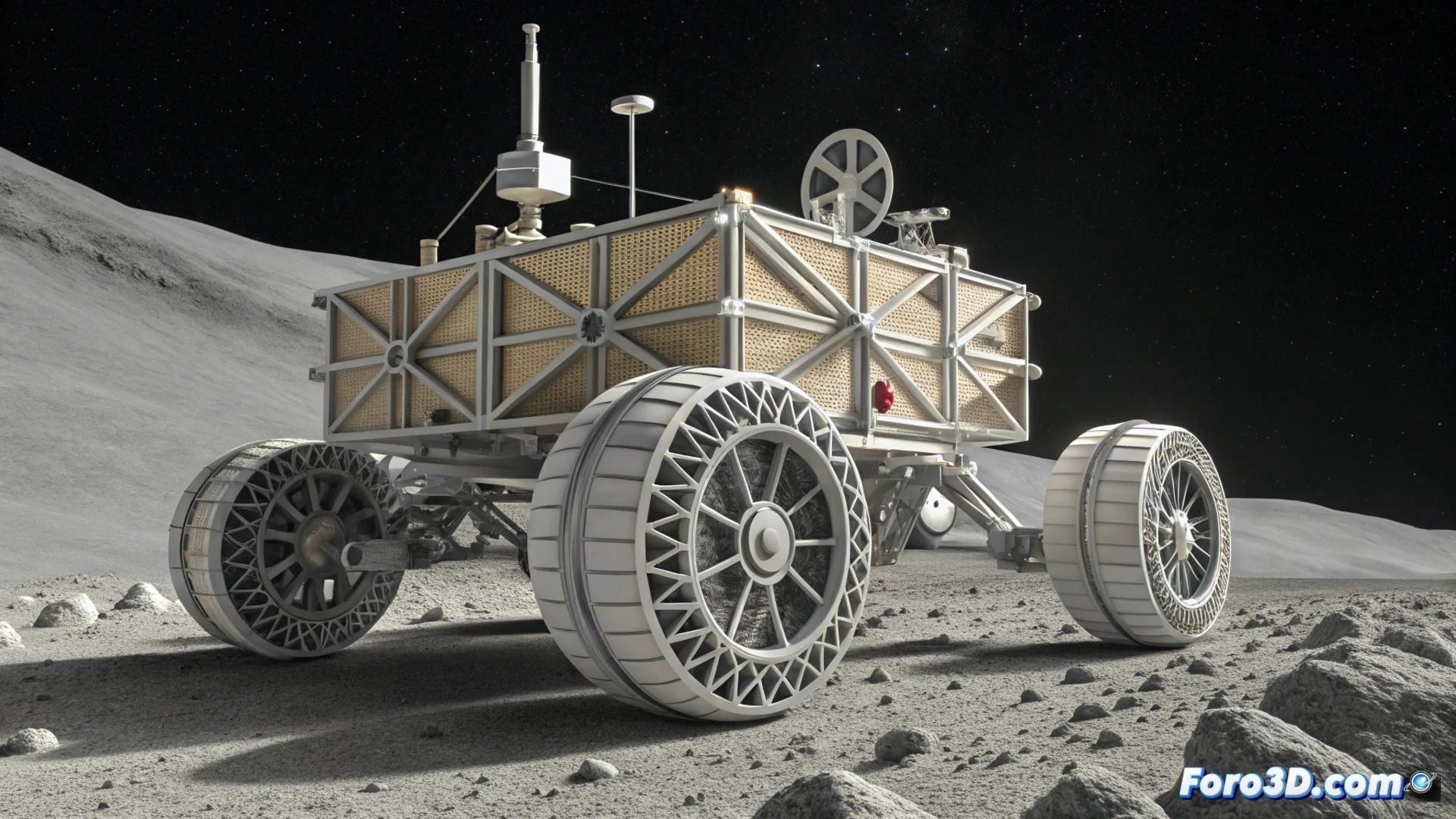

The Artemis Lunar Rover Tests 3D-Printed Components

A prototype lunar vehicle, developed by Lockheed Martin and Northrop Grumman for the Artemis program, already incorporates vital parts created with additive manufacturing. This experimental rover serves to demonstrate how 3D printing can transform space exploration, allowing tools to be manufactured and repaired far from Earth. 🚀

Validating Manufacturing on the Moon

The central purpose of this project is to verify that 3D printing technology is a practical method for producing and repairing equipment directly on the lunar surface. This concept, known as in situ manufacturing and maintenance, aims to reduce dependence on sending every spare part from our planet.

Key advantages of manufacturing in space:- Design complex parts: Allows creating lightweight and optimized geometries that are difficult or expensive to achieve with traditional manufacturing methods.

- Reduce launch payload: Minimizes the need to transport a large inventory of spares, making missions cheaper and simpler.

- Use local resources: Opens the door to employing materials like lunar regolith, increasing the autonomy of permanent bases.

The next time a lunar rover needs a new wheel, the solution could be as simple as sending a digital file to the base's printer.

The Prototype as a Test Bench

This rover is not yet intended to roll on the Moon, but to function as a test platform on Earth. Engineers evaluate how 3D-printed components perform under conditions mimicking the lunar environment, collecting crucial data to refine designs.

Elements under evaluation:- Wheels and suspensions: Tested on rough and sandy terrains to measure their durability and traction.

- Tools and structural components: Their functionality is verified for tasks like sampling or building.

- Environmental tolerance: Ensures parts can withstand vacuum, extreme temperatures, and high radiation.

A Self-Sufficient Future

This advancement represents a paradigm shift in space logistics. By validating additive manufacturing for critical missions, the foundations are laid for astronauts to respond to unforeseen needs by fabricating solutions on the fly. The success of these tests brings closer the vision of more flexible, durable, and economically viable lunar exploration. 🌕