The 4D Printing Revolution: When Objects Come to Life

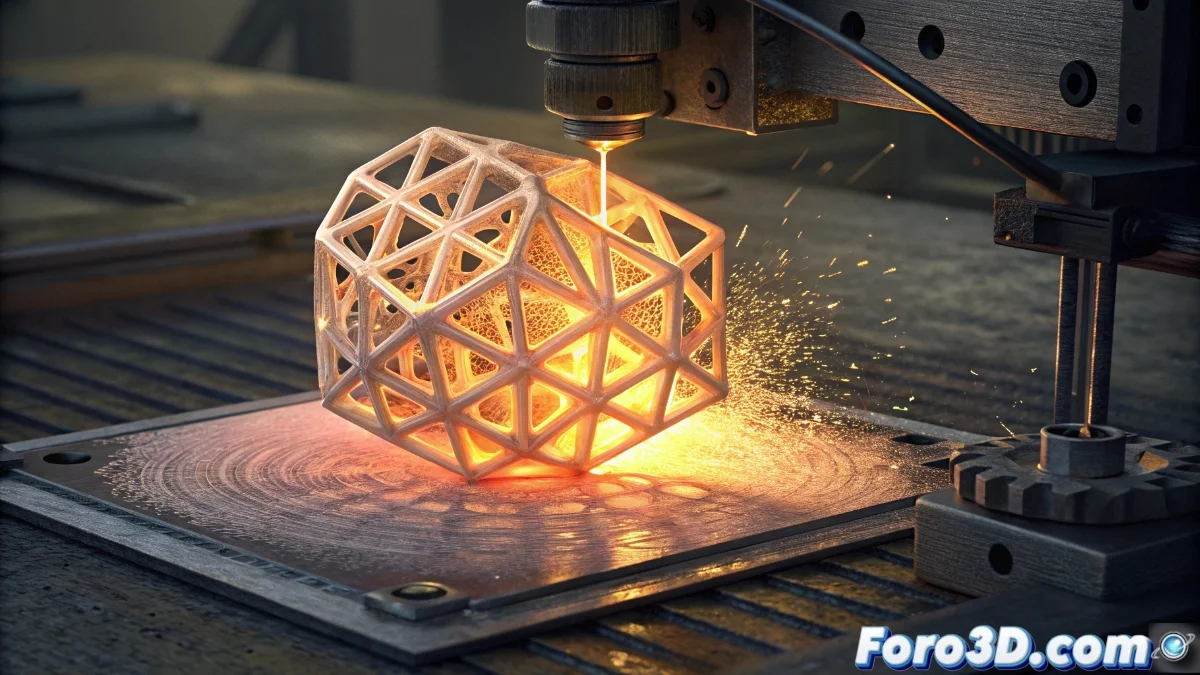

4D printing marks a technological milestone by transcending the limitations of conventional three-dimensional manufacturing, integrating the temporal dimension as a fundamental component in the creation process. These manufactured elements possess the intrinsic capacity to transform their morphology, dimensions, or physical characteristics when subjected to specific external stimuli, opening new frontiers in the fabrication of autonomous reactive systems. 🌟

Programmable Materials with Adaptive Behavior

The heart of this innovation lies in smart materials, advanced composites such as shape-memory polymers, sensitive hydrogels, and metamorphic alloys that respond to environmental variations. During the manufacturing process, these compounds are computationally programmed to execute predefined transformations upon detecting changes in temperature, humidity, light exposure, or electromagnetic fields, ensuring a controlled and functional transition.

Fundamental Characteristics of 4D Materials:- Shape-Memory Polymers: Recover their original configuration after deformation through thermal activation

- Sensitive Hydrogels: Modify their volume according to ambient humidity levels

- Adaptive Alloys: Alter their mechanical properties under specific magnetic stimuli

Temporal programming through computational design anticipates the object's evolution, ensuring that each transformation serves practical purposes in its final application.

Practical Implementations and Future Horizons

The applications of 4D printing span diverse sectors such as regenerative medicine, where vascular stents are developed that expand progressively with body heat, to sustainable architecture, with construction materials that optimize their thermal insulation according to climatic conditions. In the aerospace field, foldable components are designed that self-assemble in space, maximizing efficiency in payload transport.

Emerging Fields of Application:- Customized Medical Devices: Implants that adapt to the patient's physiology

- Responsive Infrastructure: Buildings that modify their wind permeability or solar capture

- Smart Textiles: Garments that adjust their breathability according to physical activity

The Future of Material Interaction

We envision an ecosystem where everyday objects anticipate our needs: furniture that reconfigures according to our posture, clothing that regulates its coloration in response to bodily bioactivity, creating environments that fuse comfort with technological innovation. Although challenges persist in terms of material durability and economic scalability, 4D printing promises to redefine our relationship with the manufactured world, propelling us toward an era of mass personalization and environmental sustainability. 🚀