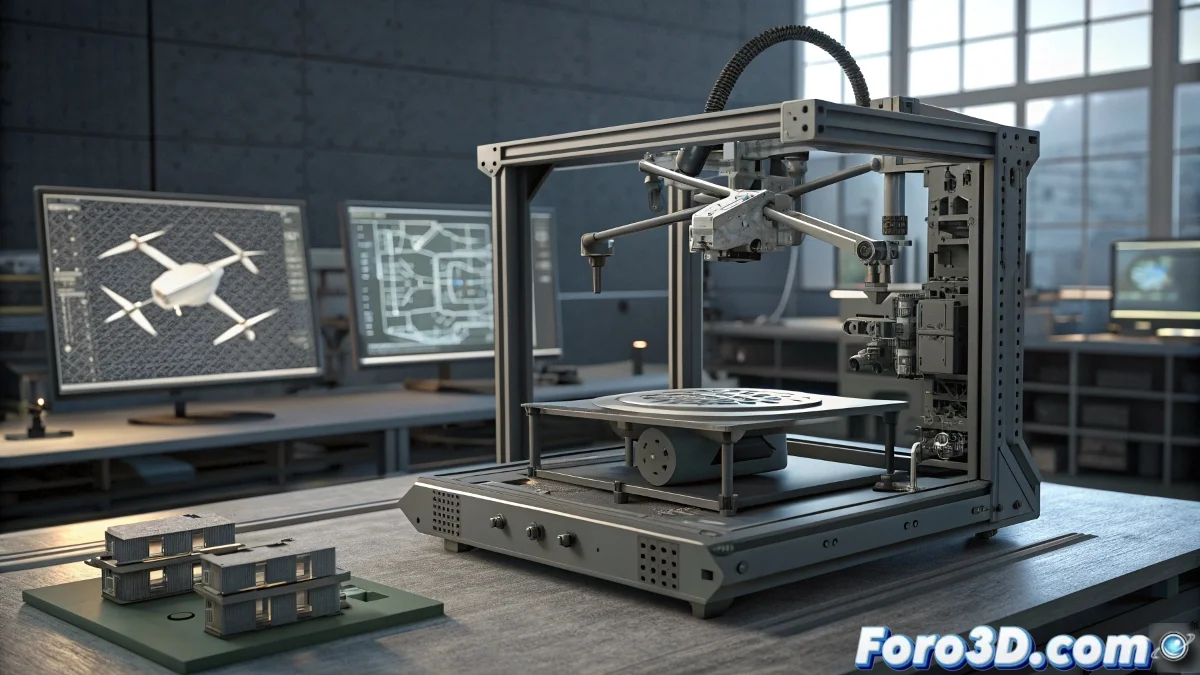

The 3D Printing Revolution in Military Drones: Advantages and Current Challenges

Additive manufacturing is radically transforming the production of unmanned aerial systems for defensive use. Countries with advanced technology are redefining their supply chains through the implementation of specialized 3D printers capable of creating critical components with geometries impossible to achieve with conventional methods 🚀

Operational Logistics Transformation

The ability to manufacture on demand represents a paradigm shift for deployed units. Technical teams can now produce spare parts in record time, adapting to the immediate needs of the theater of operations without relying on complex supply networks.

Key Strategic Advantages:- Reduction of up to 70% in production times compared to traditional methods

- Field customization for specific missions with unique requirements

- Logistical independence in remote territories or under hostile conditions

3D printing allows us to respond to tactical needs in hours instead of weeks, completely changing the rules of the game - Colonel of Engineers, European Air Force

Advances in Specialized Materials

Defense laboratories are developing high-strength polymeric compounds that surpass the limitations of conventional materials. These innovations enable the creation of components that maintain their structural integrity under extreme temperature and pressure conditions.

Materials in Development:- Carbon fiber-reinforced polymers for greater rigidity

- Ceramic composites for thermal protection in engines

- Lightweight shape-memory metal alloys

Technological Obstacles to Overcome

Despite the widespread enthusiasm, significant challenges persist in quality control and process standardization. Variability between production batches and susceptibility to electronic interference require innovative solutions before mass implementation.

Current Critical Challenges:- Ensuring dimensional consistency in long production runs

- Protection of design data against cyberattacks

- Certification of components for high-risk missions

The Immediate Future of Military Manufacturing

Technological evolution continues at an accelerated pace, with experimental prototypes that incorporate sensors directly printed into the structures. While strategists plan this manufacturing transition, combat units are already experiencing the benefits of having decentralized production capabilities that significantly increase their operational autonomy 💪