Technology Centers Automate Battery Dismantling

The need to recycle batteries on a massive and safe scale drives research centers like Eurecat to develop fully automated systems. These processes are essential for recovering valuable metals and handling complex waste without exposing people to risks. Automation redefines how we approach the end-of-life of these components 🔋.

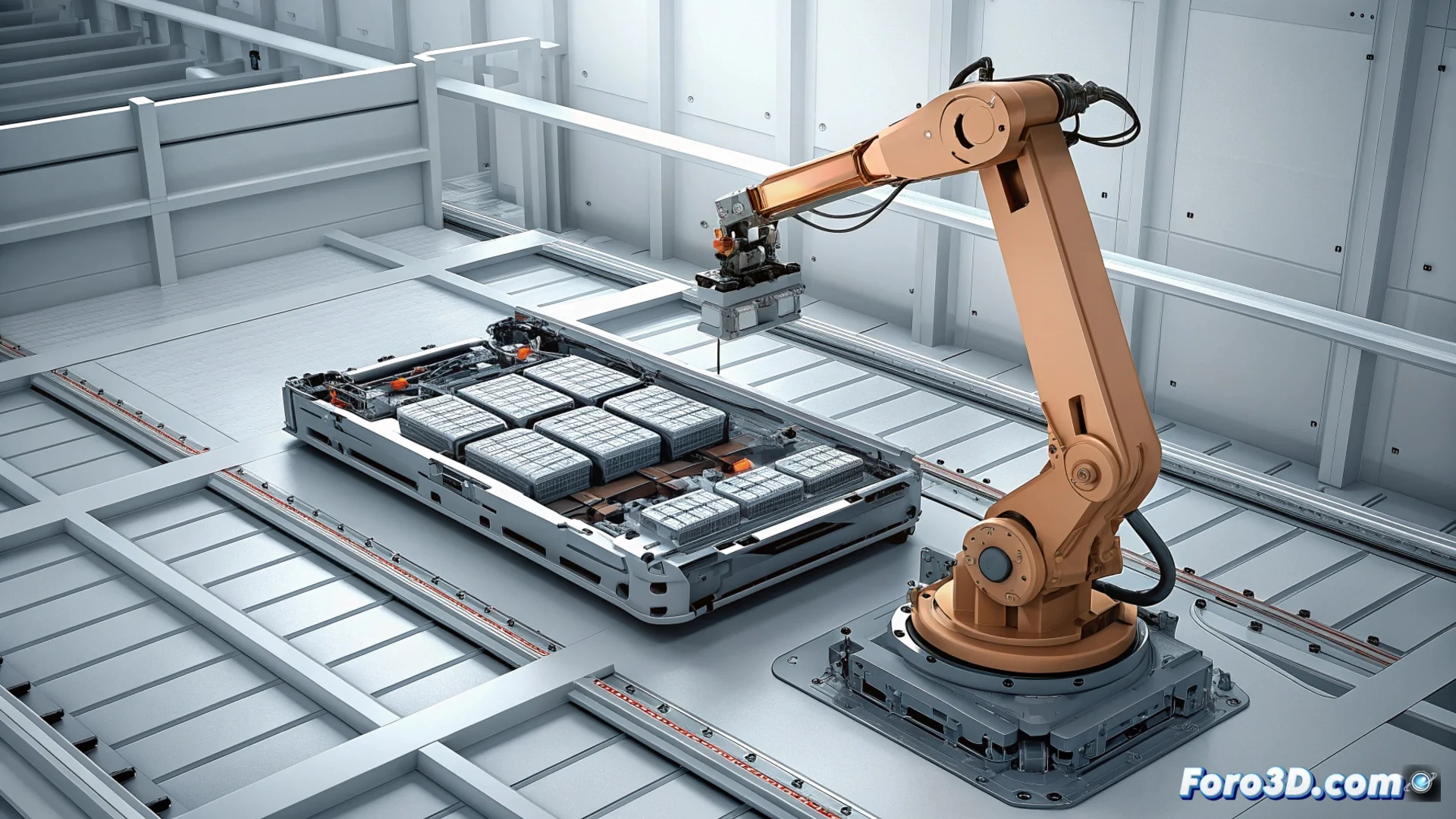

Robots Performing High-Precision Tasks and Handling Hazards

Robotic lines employ robotic arms equipped with special tools and machine vision. These systems locate and remove fastening elements, disconnect electrical components, and extract individual cells. Their flexibility allows them to adapt to various battery models, a key factor given the rapid technological evolution. Automation enables processing a large volume of units consistently, something difficult to achieve with manual methods.

Key Advantages of Automation:- Eliminates human error and increases traceability of each piece.

- Allows handling of hazardous or toxic components in a controlled environment.

- Optimizes recycling by ensuring greater purity in recovered materials.

Ongoing research seeks to make these systems even faster and more selective to process different battery chemistries.

Driving a Circular Economy for Critical Metals

By effectively recovering cobalt, nickel, and lithium, the need to extract new minerals is reduced. This mitigates the environmental impact of mining and ensures a more stable supply of raw materials. Automated processes make recycling economically viable on a large scale.

Impact on the Supply Chain:- Advances toward a model where used batteries are a source of resources, not waste.

- Contributes to greater independence from geopolitically sensitive resources.

- Establishes a secondary and sustainable supply for the manufacturing industry.

A Future Built on Recovered Resources

Automated dismantling is not just a matter of efficiency; it is a pillar for a sustainable industry. By closing the battery life cycle, we transform a logistical and environmental challenge into a strategic opportunity. Robots, in this task, take on the risky work of disassembling what we assembled, allowing valuable materials to return to the production circuit ♻️.