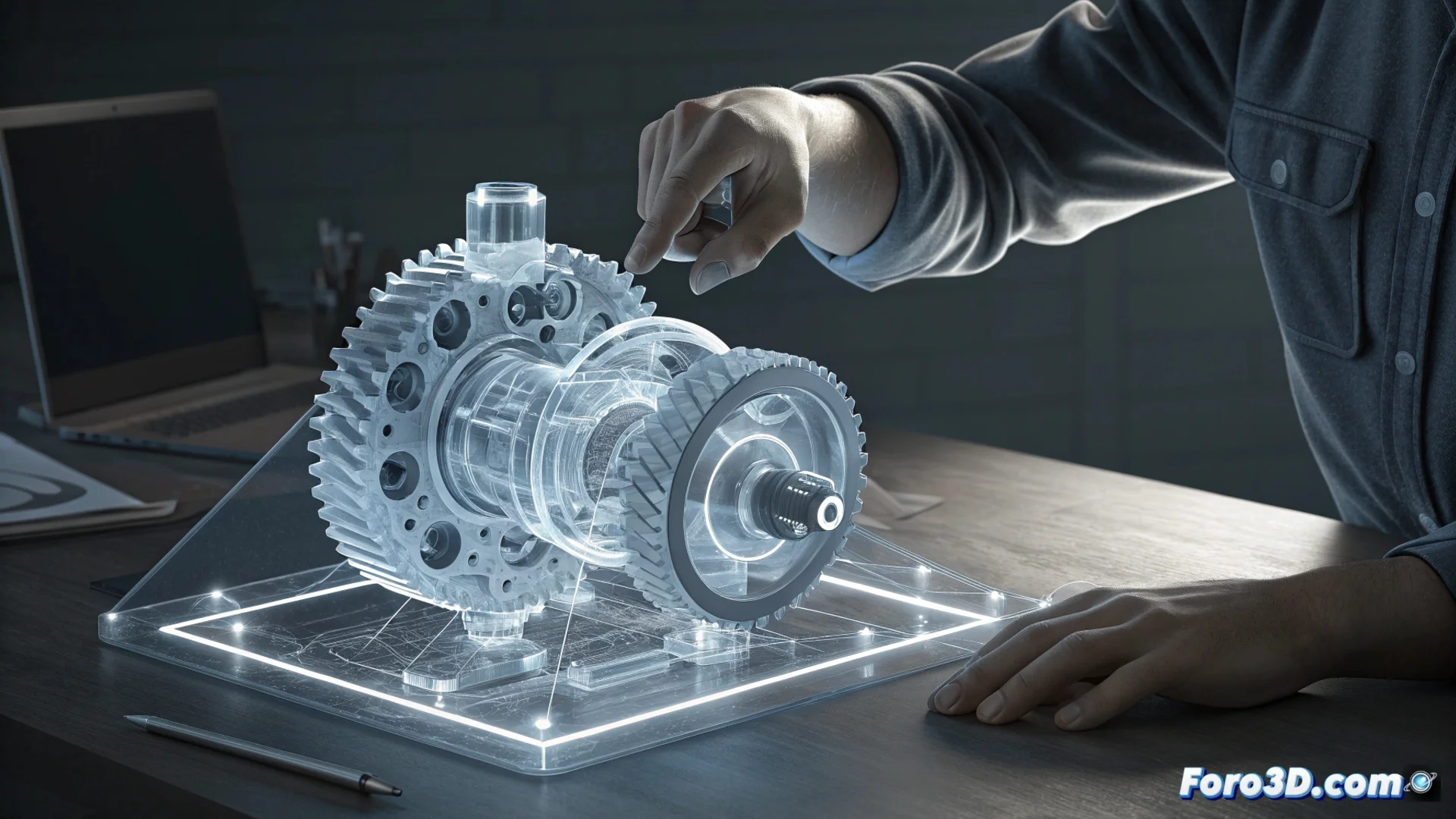

Synchronous Technology Fuses Direct and Parametric Modeling

A modern 3D design program integrates a revolutionary approach that eliminates the traditional dichotomy between two methods. This system unifies the agility to manipulate shapes with dimensional rigor, creating a smoother and more intuitive work environment. 🚀

A Modeling Engine that Interprets the Designer's Intent

Synchronous technology is not a separate mode, but the core of a unified modeling engine. When the user pushes or pulls the faces of a model directly, the system analyzes and interprets the action automatically. In the background, it applies constraints and parametric dimensions to maintain precision and defined relationships. This allows modifying an imported file without parameters or adjusting a complex design without rebuilding its dependency chain.

Key Advantages of This Unified Approach:- Edit Without History Limits: Modify geometry without depending on a linear sequence of operations that may block later changes.

- Maintain Design Integrity: The software resolves modifications in real time, preserving specified geometric relationships.

- Work with Any Geometry: Equally effective for editing native parametric models and CAD files imported from other systems.

Parametric precision operates in the background, allowing freedom to create and modify without sacrificing control.

Transforming the Design Workflow

This ability to edit flexibly significantly accelerates many processes. Designers can quickly reuse and adapt existing geometry, experiment with concepts agilely, and collaborate in teams without modifications generating conflicts. The model remains consistent at every stage, helping to reduce the total time to develop a product.

Practical Benefits in Real Projects:- Streamline Reuse: Adapting existing parts or assemblies, even from other CAD packages, becomes a direct task.

- Encourage Experimentation: Test shape and size variations quickly, without fear of breaking references or complex dependencies.

- Facilitate Collaborative Work: Changes from different team members integrate more smoothly, maintaining project coherence.

Adapting to a New Modeling Paradigm

For users accustomed to the security of a sequential operations tree, the initial change may feel like driving without brakes. However, parametric control does not disappear, but becomes implicit and adaptive. The end result is a 3D design environment that offers both creative freedom and the technical accuracy necessary for professional projects, marking a turning point in how digital geometry is conceived and modified. 💡