Subaru Shortens Deadlines for Making Jigs with Large-Volume 3D Printing

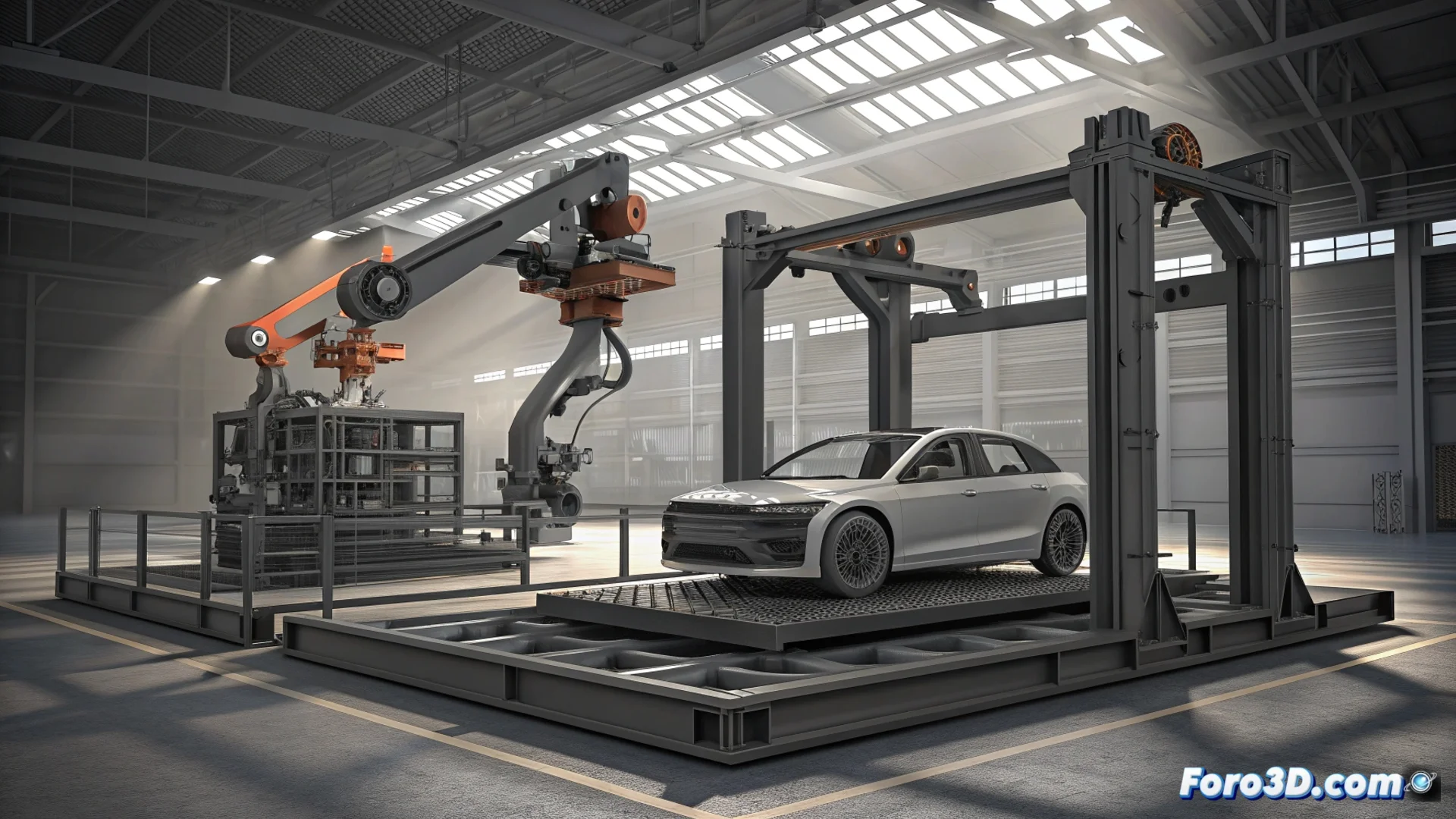

The automotive brand Subaru has integrated a large-volume additive manufacturing system into its Lafayette, Indiana plant. This technology is used to produce assembly tools internally, radically transforming how it supplies its assembly line 🛠️.

Drastically Reduce Delivery Times

By printing these jigs in the factory itself, Subaru manages to shorten delivery deadlines from several weeks to just a couple of days. These tools are essential for aligning and holding components during vehicle assembly. The ability to produce on demand provides unprecedented operational flexibility.

Key advantages of in-house manufacturing:- Eliminate dependence on external suppliers and their long traditional cycles.

- Respond agilely to changes in the production line or needs for specific models.

- Maintain the manufacturing pace without interruptions due to lack of tools.

The motto "Confidence in motion" now also defines the tools department, which no longer has to wait months to act.

Advanced Materials for a Demanding Industrial Environment

The technology used employs a carbon fiber composite infused with thermoplastic. This material provides the rigidity and robustness necessary to withstand the harsh environment of an automotive assembly line ⚙️.

Characteristics of the composite used:- Offers strength and durability comparable to metal tools.

- Allows printed parts to be used repetitively alongside metal components.

- Meets all functional requirements for which each jig is designed.

A Strategic Change in Manufacturing

This implementation represents a strategic step to optimize the production chain. It is not just about adopting a new technology, but about redesigning a critical process. Large-format 3D printing allows Subaru to be more agile, self-sufficient, and capable of customizing its operations, consolidating a more resilient and efficient manufacturing process 🚗.