The Art of Simulating Motion in SolidWorks

Simulating the behavior of assembled mechanisms in SolidWorks is like predicting the future of your design 🔮. The crucial question is not whether you can jump straight into complex analysis, but whether you should. While technically possible to go directly to a full Motion Study, practical wisdom often recommends a more methodical approach that avoids headaches later.

Prior Study or Direct Immersion?

The beauty of SolidWorks lies in its flexibility: it is not strictly mandatory to perform a prior motion study if your assembly has well-defined constraints. However, jumping straight into complex dynamic analysis without first validating basic behavior is like building a skyscraper without foundations – technically possible, but potentially disastrous 🏗️.

One minute of prior verification saves hours of later debugging.

When Prudence Triumphs Over Speed

Certain scenarios scream for preliminary validation before committing to complex simulations. Recognizing these situations separates casual users from experienced professionals.

- Complex mechanisms: Systems with multiple interconnected parts

- Novel constraints: Unusual or custom mates

- History of issues: Assemblies that previously presented problems

- Critical designs: Mechanisms where failure is not an option

The Ideal Staggered Workflow

Advanced users follow a logical progression that maximizes efficiency while minimizing risks. This layered approach allows detecting and correcting issues in early stages, when they are easier to resolve.

- Basic animation: Visual verification of motion and degrees of freedom

- Kinematic analysis: Mathematical validation of trajectories and velocities

- Dynamic simulation: Application of forces, frictions, and contacts

- Final optimization: Fine-tuning based on simulation results

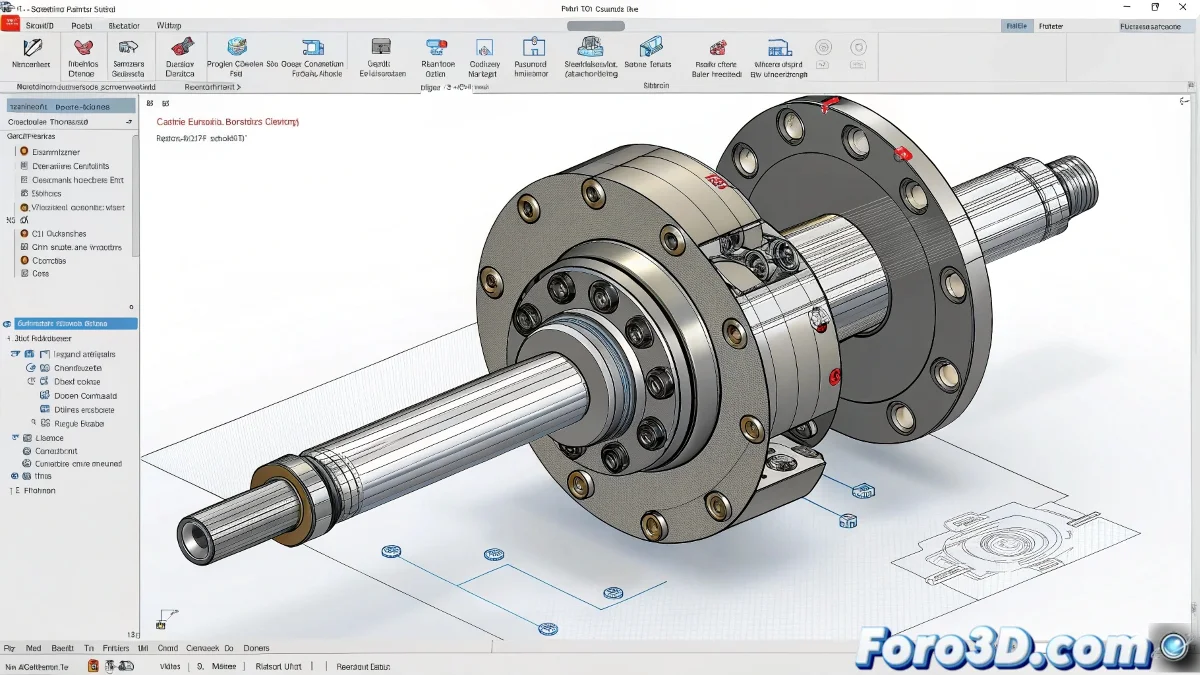

Practical Setup in SolidWorks

Implementing this staggered workflow is surprisingly straightforward within the SolidWorks environment. The Motion Study Manager is specifically designed to facilitate this incremental transition.

- Motion Study tab: Quick access to different types of analysis

- Automatic conversion: Basic studies can evolve into complex ones

- Configuration preservation: Mates and constraints are maintained between studies

- Analysis tools: Graphs and metrics for each simulation level

Warning Signs That Require Prior Study

Certain symptoms clearly indicate that your assembly needs preliminary validation before advanced simulation attempts. Recognizing these red flags saves time and frustration.

- Incorrect degrees of freedom: Parts that move in undesired directions

- Mate conflicts: Constraints that overlap or contradict

- Erratic behavior: Unpredictable movement during manual manipulation

- System warnings: SolidWorks alerts about problematic constraints

The Perfect Balance Between Rigor and Efficiency

The final decision always lies in finding the right balance for each specific project. Experience and intuition play a crucial role in determining how much preliminary validation is necessary.

And when your simulation decides that the laws of physics are mere suggestions, you can always argue that you've discovered a new form of energy 🚀. After all, in the CAD world, sometimes simulation errors lead to real innovations.