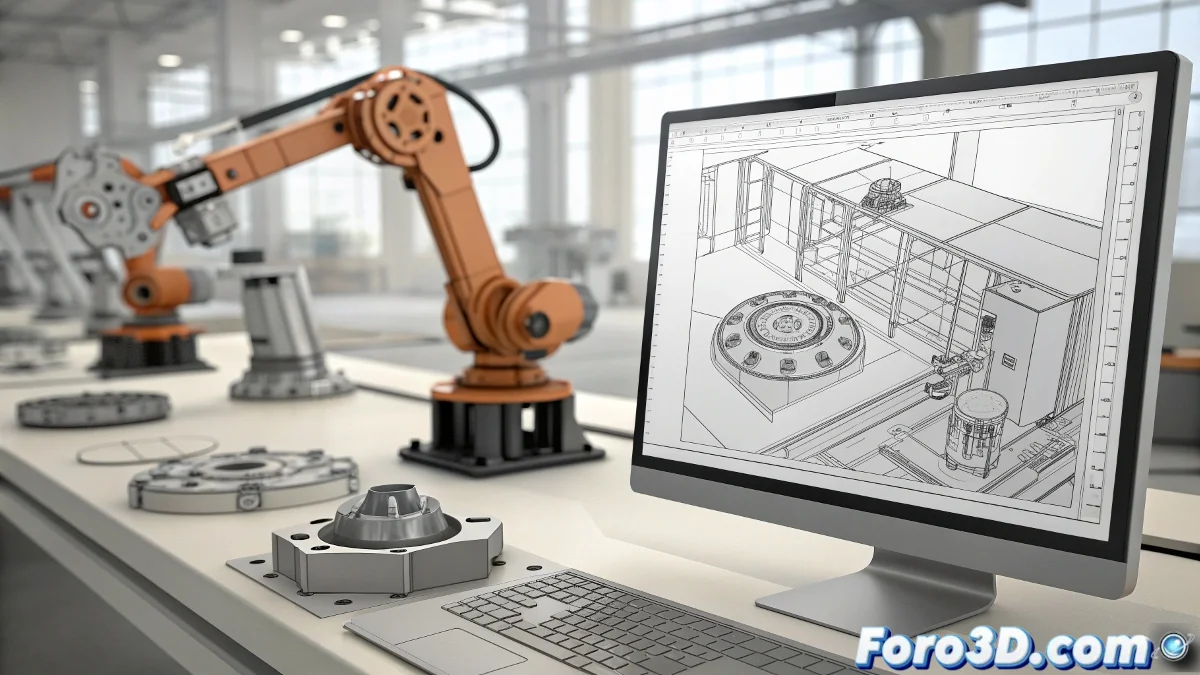

Spare Parts 3D Revolutionizes Digitization with AI: From 2D Drawings to 3D Models in Seconds

The French startup Spare Parts 3D, specialized in the digital transformation of spare parts inventories, has just launched the beta version of an artificial intelligence tool that promises to change the game in the industry. Its new system is capable of automatically converting 2D technical drawings into complete digital 3D models, addressing one of the biggest bottlenecks in spare parts digitization: the manual conversion of legacy paper documentation into printable digital formats. 🚀

Advanced Technical Drawing Recognition: More Than Simple OCR

What makes this tool unique is its ability to understand the semantics of technical drawings. It goes far beyond simple optical character recognition (OCR); the AI analyzes multiple views (plan, elevation, profile), interprets dimensions and tolerances, recognizes surface finish symbols, and understands technical representation conventions. The system is capable of inferring complex 3D geometries from information scattered across different views, reconstructing parts with through holes, chamfers, rounds, and other features that would normally require expert manual modeling. 🔧

AI Interpretation Capabilities:- simultaneous analysis of multiple orthogonal views

- interpretation of linear, angular, and diameter dimensions

- recognition of welding and finish symbols

- understanding of geometric and dimensional tolerances

Optimized Workflow for Industrial Companies

The process is specifically designed for enterprise environments with large volumes of legacy technical documentation. Users can upload batches of scanned drawings, and the tool automatically processes each one, generating 3D models ready for review. It includes a two-step verification system: first, the AI identifies areas of uncertainty and requests human confirmation; second, it generates quality reports that highlight possible discrepancies between the original drawing and the generated 3D model. This hybrid approach ensures accuracy without sacrificing speed. 📊

Digitizing spare parts is no longer a luxury; it is a strategic necessity for Industry 4.0

Integration with Additive Manufacturing Ecosystem

The generated models are exported ready for digital manufacturing in native formats (STEP, IGES) and for 3D printing (STL, 3MF). The tool includes automatic optimization features for additive manufacturing, suggesting orientations, support structures, and printing parameters based on the selected material. This direct integration with the digital manufacturing workflow means companies can go from a paper drawing to a functional physical part in hours instead of weeks. 🏭 Available Export Formats:

- STEP and IGES for integration with CAD software

- STL and 3MF optimized for 3D printing

- OBJ and FBX for visualization and presentations

- PDF reports with quality metrics and verification

Applications in Spare Parts Management and Maintenance

For companies with extensive inventories of obsolete spare parts, this tool represents a monumental advance. It allows rapid digitization of parts for which molds or manufacturing tools no longer exist, facilitating the transition to on-demand manufacturing business models. Sectors such as aeronautics, rail, and energy—where equipment can have decades-long service lives—will find special value in this ability to resurrect spare parts from old documentation. ✈️

Beta Program: Open Collaboration with Industry

Spare Parts 3D has opted for a collaborative development approach for its tool. The beta program is open to industrial companies that wish to test the technology with their own drawings, thereby contributing to training and refining the AI algorithms. Participants gain priority access to the final version and significant discounts on digitization services. This strategy not only accelerates development but ensures the final tool solves real industry problems. 🤝

Benefits for Beta Tester Companies:- free access during the trial period

- direct influence on feature development

- priority technical support from the Spare Parts 3D team

- preferential conditions in the commercial version

The launch of this beta tool by Spare Parts 3D marks a significant milestone in the evolution of digital manufacturing. By addressing the initial digitization bottleneck, it not only accelerates the adoption of 3D printing in industry but democratizes access to additive manufacturing for companies that previously considered the cost of converting their paper drawing repositories prohibitive. In a world where supply chain agility and resilience are critical, tools like this could become the lifeline that many companies need. The revolution in digital spare parts has just accelerated dramatically. 💥