SolveSpace Incorporates Kinematic Link Constraints for Dynamic Design

The SolveSpace platform revolutionizes traditional mechanical design through the implementation of kinematic link constraints that transform static models into fully interactive experiences. This innovative capability allows establishing advanced geometric connections between multiple components, where the displacement of a specific element automatically generates synchronized transformations throughout the configured mechanical system 🎯.

Configuration of Simulated Mechanisms

To create a functional kinematic system, basic geometric elements such as reference points, linear segments, and circular contours representing real physical components are first established. Subsequently, dimensional and angular constraints are applied to define the desired kinematic relationships between these elements. Activating the dynamic link requires selecting the components that will maintain rigid connection during operation, while specifying a main control point that will direct the animated sequence.

Step-by-Step Configuration Process:- Definition of fundamental geometries (points, lines, circles) representing physical components

- Application of distance, angle, and coincidence constraints for kinematic relationships

- Selection of interconnected elements and designation of the animation driving point

The system automatically maintains all defined geometric relationships while allowing articulated movement within the permitted degrees of freedom

Applications in Mechanical Engineering

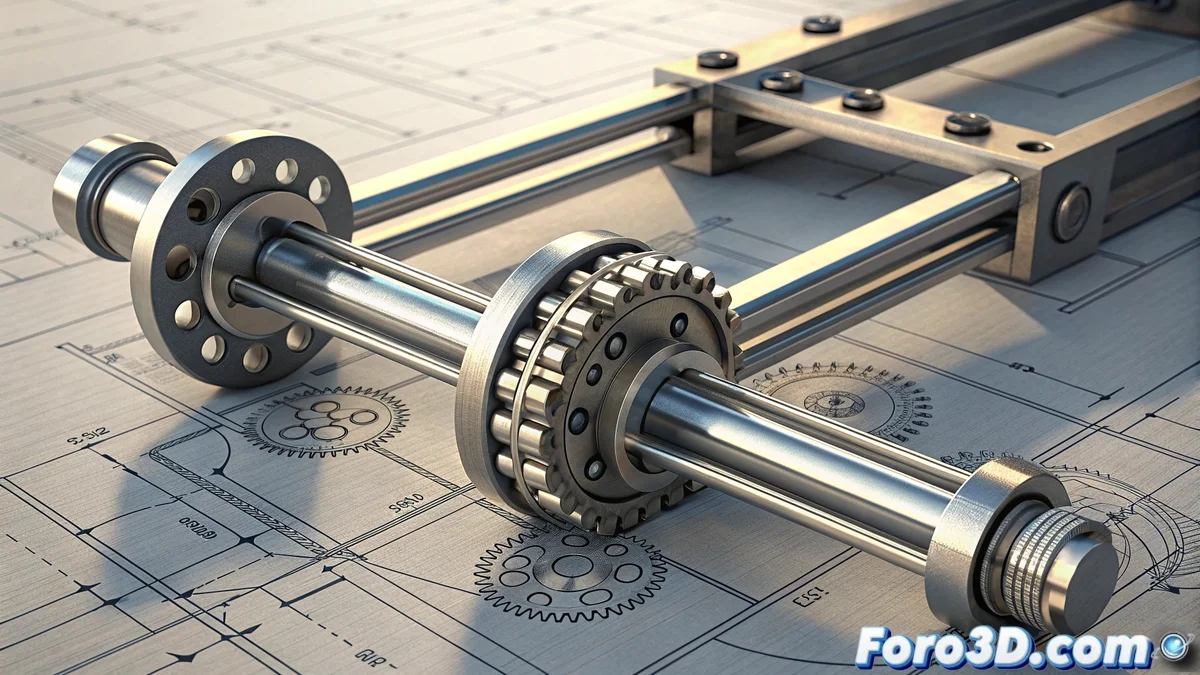

This functionality is especially valuable for verifying complex mechanisms before the manufacturing process, allowing identification of interferences, locked positions, or limitations in movement ranges. Engineers can model sophisticated systems such as four-bar mechanisms, universal joints, vehicle suspension configurations, or any set of interconnected elements where the behavior of one part directly influences others.

Main Advantages in Mechanical Design:- Early detection of interferences and dead points in mechanisms

- Optimization of dimensions and geometric relationships for desired kinematic behavior

- Rapid exploration of multiple configurations with real-time parametric adjustment

Practical Considerations

Interactive simulation provides immediate feedback on design feasibility and contributes to optimizing dimensional parameters to achieve the target kinematic behavior. Users can quickly explore various configurations, modifying variables and observing their impact on the overall mechanism performance. It is important to mention that occasionally the solver may generate unexpected solutions, transforming apparently perfect mechanisms into abstract configurations, demonstrating that even computational algorithms have their creative moments 🤖.