Solution to Error E25 on Bamboo Printer: Z-Axis Diagnosis and Repair

When your Bamboo printer displays the E25 code, it is alerting about critical issues in the Z-axis that require immediate attention. This failure usually arises from step loss in the motor or mechanical misalignments, causing the print head to not maintain the correct height during vertical movements. The consequences include collisions with the printed part and visibly uneven layers, interrupting the manufacturing process. ⚠️

E25 Error Diagnosis Procedure

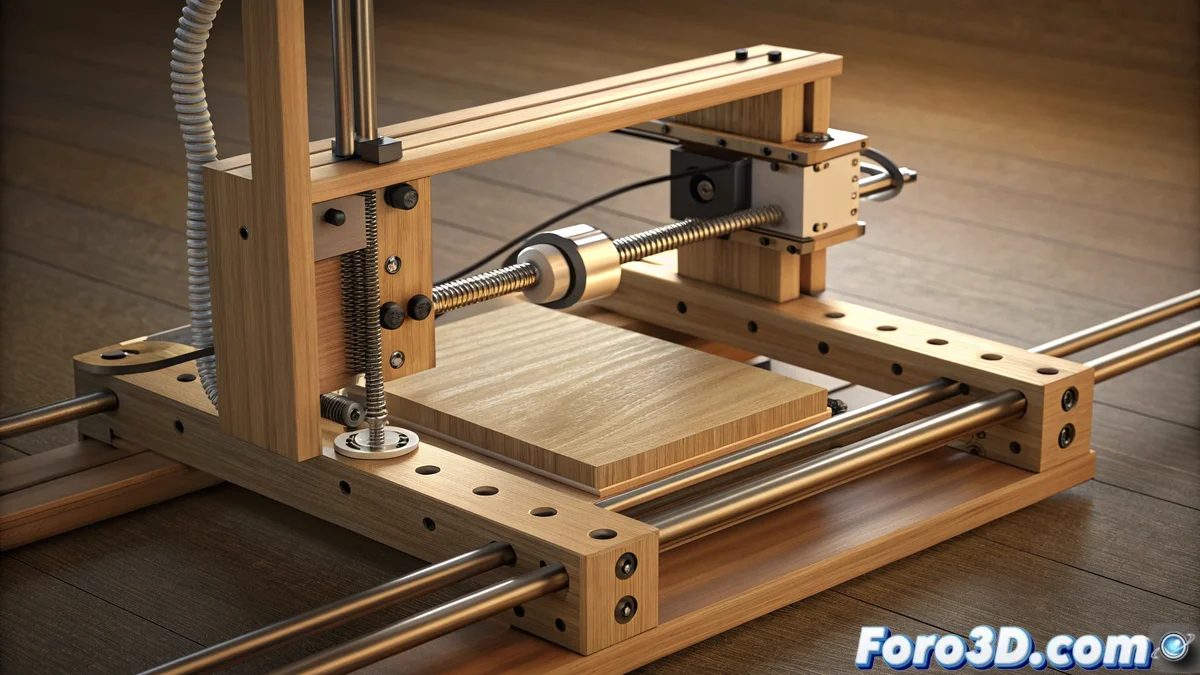

Identifying the exact origin of the problem requires a systematic verification of several components. Start by checking the tension of the Z-axis belts and ensuring that the linear guides are completely free of obstructions. It is essential to inspect the stepper motor connectors and the controller board, as loose or damaged cables can generate false step loss readings. A manual movement test from the control panel will allow you to detect irregular sounds or sudden stops during displacement. 🔍

Key elements to check:- Correct tension of the lifting system belts

- Absence of obstacles in guides and linear bearings

- Secure electrical connections on motor and controller

3D printing is a dance between mechanical precision and electronic control - when one element fails, the entire system suffers

Detailed Steps to Resolve the Error

The effective resolution of E25 involves a logical sequence of actions. Start by adjusting the motor current in the firmware, as incorrect values cause overheating and reduction in motor torque. Proceed with the cleaning and lubrication of the threaded rods using specialized 3D printer silicone grease. If the issue persists, consider replacing the Z-axis stepper motor with one of identical technical specifications. Finish by updating the printer firmware to optimize all model-specific Bamboo movement parameters. 🛠️

Correction sequence:- Adjustment of current parameters in firmware configuration

- Deep cleaning and lubrication of mechanical components

- Motor replacement if it shows irreversible wear

Final Reflections on Preventive Maintenance

Modern 3D printers like the Bamboo incorporate advanced detection systems that protect the equipment's integrity against mechanical anomalies. The E25 error acts as a safety mechanism that prevents major damage, but its frequent appearance indicates the need for regular maintenance. Establishing monthly verification routines can avoid these interruptions and ensure consistent quality prints. The next time your printer "decides to take a break," remember it is asking for help to continue serving you properly. 🤖