The Silent Revolution of Programmable Materials

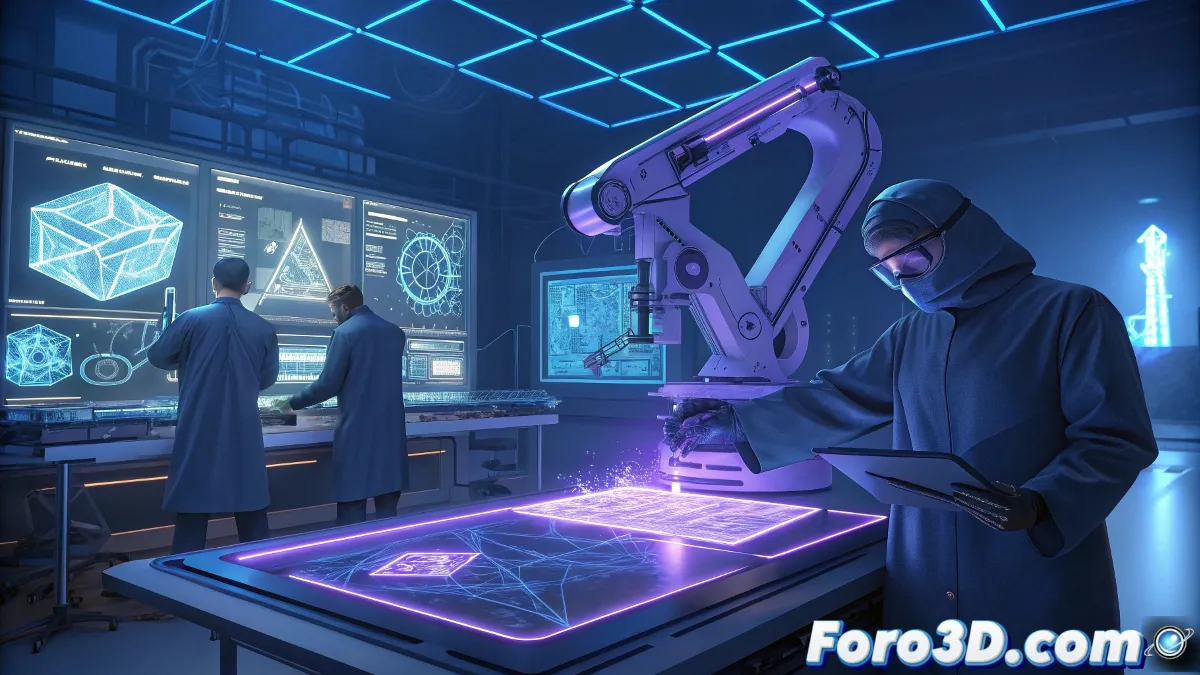

In the world's most advanced laboratories, a new generation of technologies is challenging the limits of traditional manufacturing. So-called 4D printing represents a qualitative leap forward from its predecessors, allowing objects not only to be manufactured but to evolve over time as they interact with their environment.

"We are witnessing the birth of materials with a certain form of environmental intelligence," explains a MIT researcher who prefers to remain anonymous.

Transformation Mechanisms Inspired by Nature

Shape-memory polymers form the heart of this technology. Unlike conventional materials, these structures are capable of remembering predetermined configurations and recovering them upon receiving specific stimuli. The process curiously resembles how certain plants orient their leaves toward sunlight or how some insects deploy their wings upon emerging.

Among the most promising applications are:

- Smart bandages that automatically adjust to wounds

- Aerospace components that modify their aerodynamics

- Cellular scaffolds that guide tissue growth

The Necessary Technological Ecosystem

For this material revolution to be possible, the convergence of multiple disciplines is required. Nanometric precision printing systems work together with machine learning algorithms capable of predicting material behavior under various environmental conditions.

The main technical challenges include:

- Limitations in reversible transformation cycles

- Accelerated degradation in extreme environments

- Difficulties in industrial scaling

Application Horizons

The medical field emerges as one of the main beneficiaries of these developments. Implants that can adapt to bone growth or vascular stents that modify their diameter according to physiological needs represent only the beginning of what is possible.

In the industrial realm, the ability to create components that self-assemble or repair small damages could significantly reduce maintenance costs and extend product lifespan.

Experts agree that we are facing a transformative technology, although they warn that its full maturation could still take a decade of intensive research. The true potential of these programmable materials is only beginning to emerge.