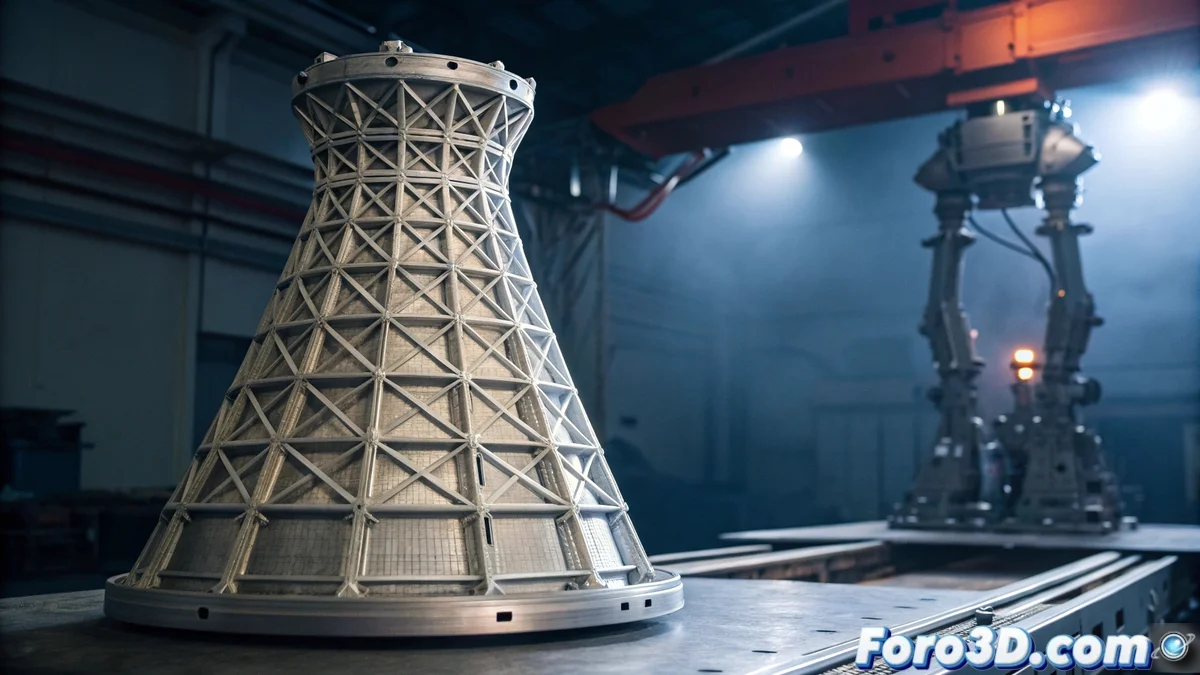

Skyrora Leads the Development of Tanbium: Advanced Alloy for 3D-Printed Space Engines

The British company Skyrora is at the forefront of a pioneering initiative backed by the European Space Agency to develop Tanbium, a revolutionary alloy composed of tantalum and niobium specifically designed for rocket engine components manufactured using 3D printing. This ambitious project, which features strategic collaboration with Metalysis and Thermo-Calc Solutions, represents a significant advancement in the pursuit of lighter, more efficient, and sustainable materials for the European aerospace industry 🚀.

Strategic Collaboration and Development Methodology

The consortium formed by these specialized companies is implementing a multidisciplinary approach that combines expertise in additive manufacturing, metal powder development, and computational simulation. The initial nine-month phase integrates multiple technology validation stages to ensure that Tanbium meets the most stringent quality standards in the space industry.

Key Project Phases:- Printing of prototypes using Skyrora's Skyprint platform to evaluate manufacturing feasibility

- Comprehensive mechanical testing of components to verify structural strength and thermal behavior

- Validation and characterization of the metal powder by Metalysis, a specialist in materials processing

- Compositional optimization through advanced simulations by Thermo-Calc Solutions to maximize mechanical properties

This collaboration significantly accelerates the development of Tanbium, facilitating its transition from laboratory environments to practical applications in operational rocket engines

Competitive Advantages and Technical Benefits

The implementation of Tanbium in critical space propulsion components promises to radically transform current design and manufacturing parameters. Preliminary estimates indicate weight reductions of up to 30% compared to conventional alloys, along with a substantial minimization of material waste and significant reductions in production costs.

Main Technical Advantages:- Massive reduction in mass of critical structural components to improve fuel efficiency

- Minimization of manufacturing waste through optimized additive manufacturing techniques

- Reduction in operational and production costs compared to traditional methods

- Ability to implement geometrically complex designs impossible to achieve with subtractive manufacturing

Strategic Impact on European Space Autonomy

This project is framed within strategic efforts to strengthen European technological autonomy in critical materials for aerospace propulsion. The successful development of Tanbium would not only enhance the competitiveness of the European space sector but also establish the foundation for future innovations in advanced materials and additive manufacturing techniques. While some initiatives seek futuristic solutions, Skyrora and its partners demonstrate that true innovation lies in smart alloys and 3D printing technologies that enable reaching space more efficiently and sustainably 🌌.