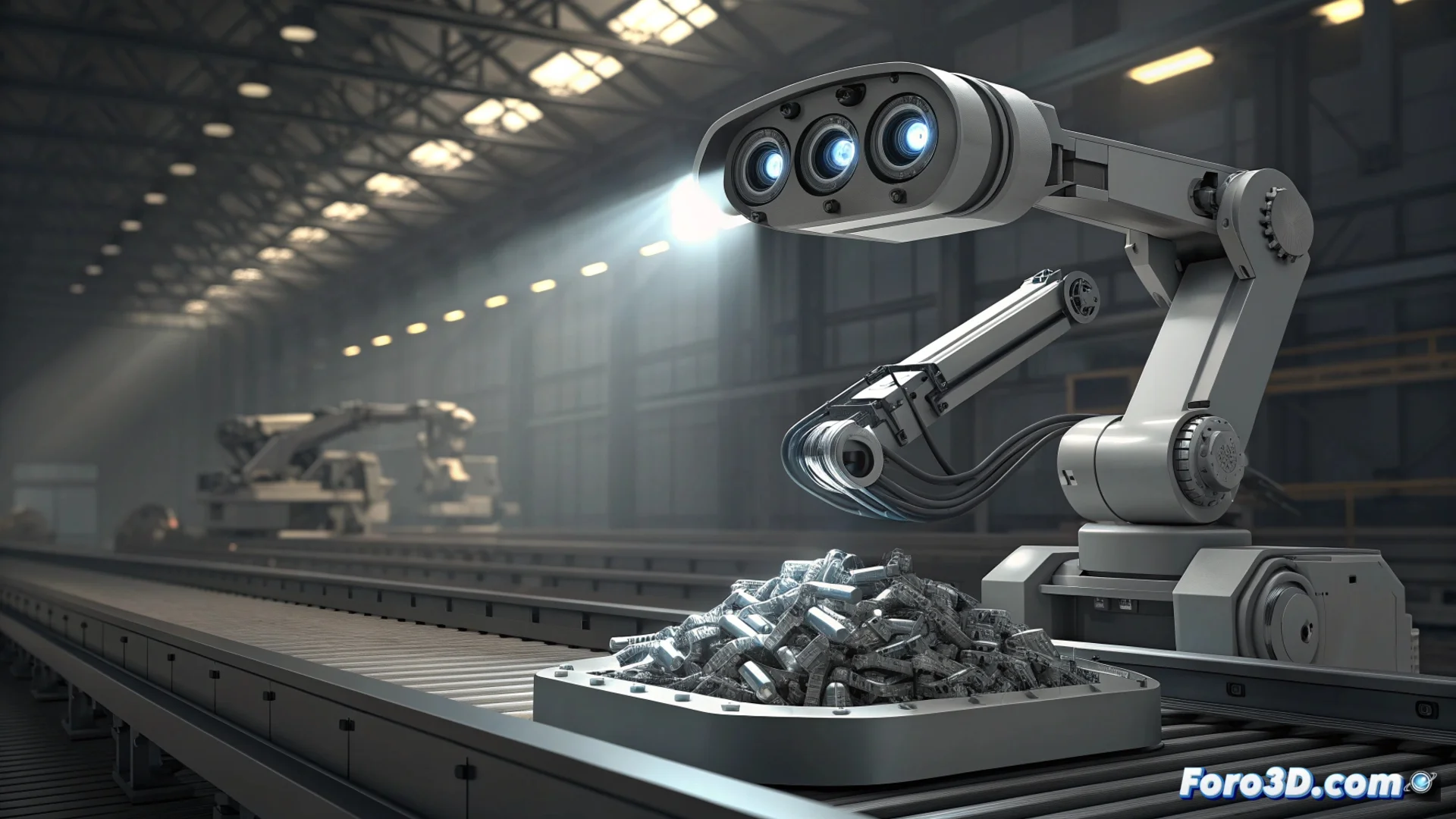

Sensopart Expands Its Catalog with the DTect Object 3D Sensor

The company Sensopart adds a new solution to its portfolio: the DTect Object 3D. This vision device is designed to perceive objects in a three-dimensional space, facilitating the inspection of components and confirming their location or presence within assembly lines and other factory environments. It operates independently, without requiring an external PC to handle the data it acquires. 🏭

A Complete System that Combines Capture and Analysis

The unit integrates into a single device a structured light projector, two CMOS image sensors, and an electronic brain for processing. By projecting a fringe pattern onto the part, the cameras record how it distorts. The internal system analyzes this data instantly to create a depth map and precise three-dimensional coordinates. This enables calculating dimensions, levels, or distinguishing piled components, without their color or composition posing an obstacle.

Key Technical Features:- Fringe pattern projection for 3D measurement.

- Two CMOS cameras to capture the pattern deformation.

- Integrated processing unit that generates the depth map in real time.

The ability to internally process 3D data eliminates dependence on external hardware, simplifying integration into the factory.

Configure and Operate from Any Browser

To adjust the sensor and design custom applications, operators access its graphical web interface via an internet browser. This platform allows easily defining scan zones, setting detection limits, and specifying parameters for decision-making. Results are transmitted using conventional digital inputs and outputs, or through network protocols like Ethernet/IP or PROFINET, enabling seamless connection to machinery and automated controls. 🔧

Communication and Integration Options:- Web interface accessible for configuration and application creation.

- Standard digital outputs for immediate control signals.

- Compatibility with industrial protocols Ethernet/IP and PROFINET to connect to PLCs and plant networks.

Potential and Practical Consideration

Although this sensor aims to simplify complex inspection tasks, its full effectiveness will depend on the end user being able to understand and use the web interface without it becoming a major technical challenge. The promise of an autonomous 3D vision that is easy to integrate marks a step forward, but its successful adoption will depend on practical experience in the workshop. ⚙️