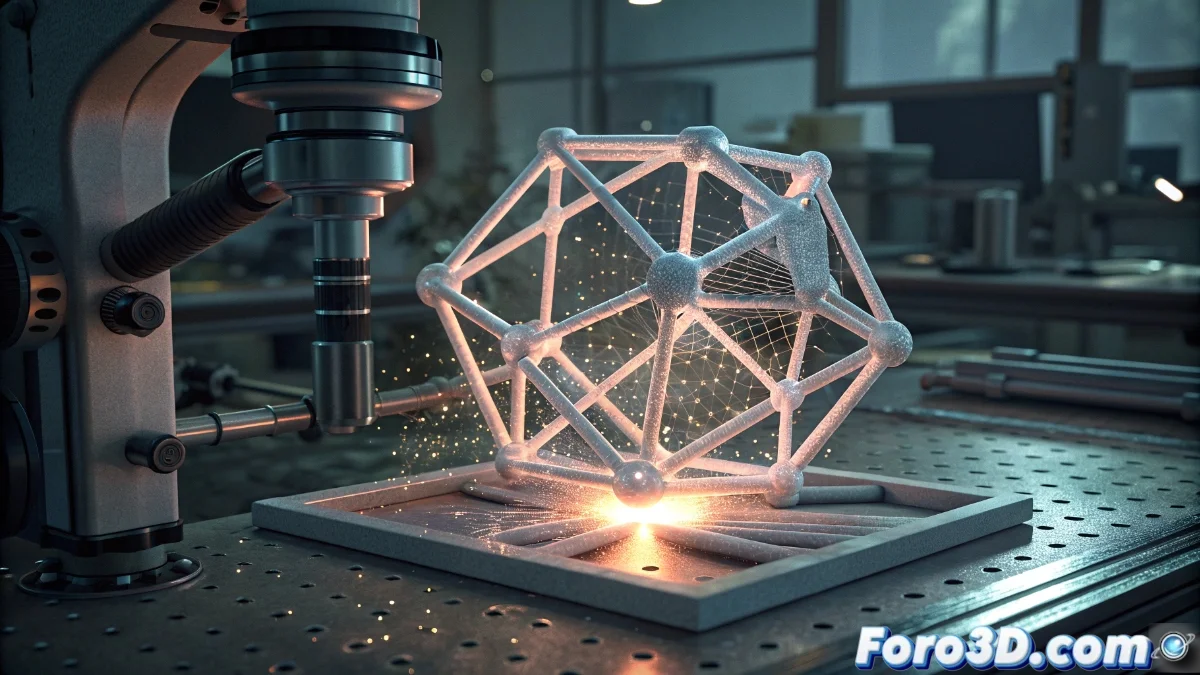

Self-Healing Materials Revolutionize 3D Printing with Smart Polymers

A research group from the Rochester Institute of Technology has developed a new generation of smart polymers capable of regenerating their mechanical properties after suffering structural damage. These innovative materials integrate microcapsule systems containing specialized chemical compounds, which activate autonomously when fractures or cracks are detected in objects manufactured via 3D printing. 🧪

Autonomous Regeneration Mechanism

The self-repair system operates through a complex network of capillary microchannels that distribute regenerative agents throughout the material matrix. When a crack occurs, these conduits release reactive compounds that interact with each other, generating new molecular bonds. The process can be repeated multiple times in the same affected area, recovering up to 85% of the initial mechanical strength of the component according to laboratory tests. 🔧

Main features of the system:- Capillary distribution network ensuring complete coverage of the structure

- Automatic activation upon any detectable fracture or crack

- Multiple regeneration capacity in previously damaged areas

The technology represents a transcendental advance for applications where the durability and longevity of components are critical functioning factors.

Implementation in Strategic Sectors

These self-healing materials find immediate application in high value-added industries such as aeronautics, where they can significantly reduce maintenance costs for structural elements. In the medical field, they enable the manufacture of prostheses and implants with greater lifespan and superior safety levels. The automotive industry also benefits by incorporating them into critical components subjected to constant wear and intense vibrations. 🚗

Highlighted fields of application:- Structural components in aeronautics and aerospace

- Implantable medical devices and customized prostheses

- Critical mechanical elements in motor vehicles

Future of Self-Repair in 3D Printing

We envision a future scenario where 3D printers could automatically notify when a part suffers damage and proceed with its autonomous regeneration while the user continues with their normal activities. This disruptive technology will not only improve efficiency in manufacturing but will radically transform the concepts of maintenance and durability in additive manufacturing. ✨