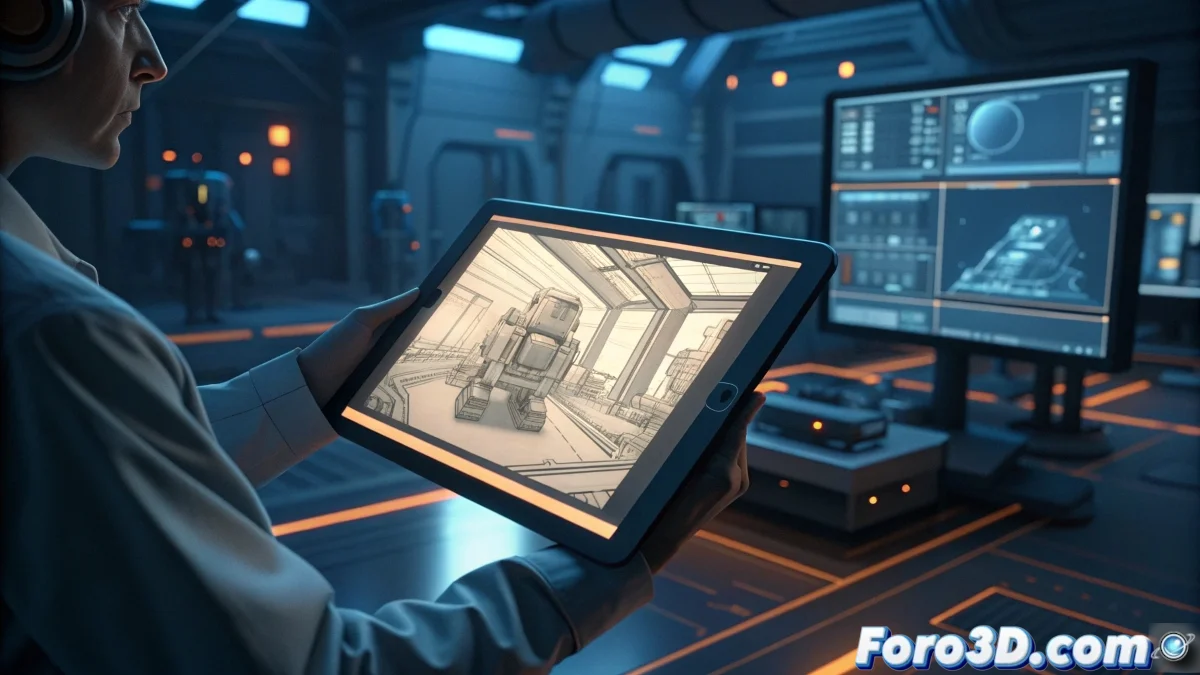

SelectAM Identify Spring 25: When AI Turns 2D Ideas into 3D Realities

In a move that promises to further democratize access to 3D modeling, SelectAM has presented its new tool Identify Spring 25, an artificial intelligence system specialized in the automatic conversion of 2D images to printable 3D models. This innovation arrives to radically transform workflows in additive manufacturing, allowing engineers, designers, and even non-specialists to convert schematics, sketches, or photos into 3D geometries ready for printing in minutes, not hours. 🎯

Intelligent Geometry Recognition: Beyond Simple Extrusion

What differentiates Identify Spring 25 from previous tools is its ability to understand the design intent behind a 2D image. It doesn't just extrude silhouettes; it analyzes construction lines, recognizes repetitive patterns, identifies technical features like holes, chamfers, and fillets, and reconstructs the parametric logic of the original design. The system can distinguish between contour lines, hidden lines, and dimensions, creating 3D models that maintain the geometric and functional integrity of the initial concept. 🔍

Advanced Conversion Capabilities:- recognition of multiple views and 3D reconstruction

- automatic identification of manufacturing features

- detection of patterns and repetitive elements

- interpretation of dimensions and tolerances in technical drawings

Optimized Workflow: From Sketch to Printer in Minutes

The process with Identify Spring 25 is remarkably intuitive. Users simply upload their image (whether a scanned technical drawing, digital sketch, or even a photo of a paper drawing), and the AI processes the information to generate an editable 3D model. The tool includes an integrated editor for refinements where parameters can be adjusted, problematic geometries corrected, and the design optimized for additive manufacturing. The final result is exported directly in standard formats (STL, 3MF, STEP) ready for slicing and printing. ⚡

The best tool is the one that removes barriers between the idea and physical reality

Optimization for Additive Manufacturing: Print-Ready Design

Identify Spring 25 doesn't just convert 2D to 3D; it automatically optimizes the models for the specifics of 3D printing. The AI analyzes the generated geometry and suggests ideal orientations, detects areas that may need supports, identifies potential bridging issues, and recommends minimum wall thicknesses based on the selected material. This predictive capability significantly reduces printing failures and iteration time, especially valuable for users with limited experience in design for additive manufacturing. 🖨️ Automatic Optimization Features:

- detection and correction of non-manifold geometries

- wall thickness optimization for different materials

- analysis of critical angles for supports

- orientation suggestions for better surface quality

Practical Applications: From Prototyping to Final Parts

The applications of Identify Spring 25 span multiple industries and scenarios. Automotive companies can quickly digitize legacy drawings for spare parts, design studios can turn concept sketches into functional prototypes in hours, and educators can teach 3D design principles without the traditional CAD software learning curve. Even for obsolete replacement parts where only paper drawings exist, this tool offers a tremendously efficient digitization and reproduction solution. 💼

Integration with SelectAM Ecosystem: A Complete Workflow

The new tool integrates seamlessly with the existing SelectAM ecosystem, enabling a continuous workflow from conceptualization to manufacturing. Generated models can be sent directly to SelectAM's simulation modules for structural analysis, then to job preparation systems, and finally to print monitoring. This vertical integration positions Identify Spring 25 not as an isolated tool, but as the natural entry point to the complete universe of SelectAM's additive manufacturing. 🔗

Main Use Cases:- digitization of legacy technical drawings

- rapid prototyping from conceptual sketches

- reverse engineering of parts from photos

- education in design and digital manufacturing

SelectAM Identify Spring 25 represents a significant paradigm shift in how we approach 3D content creation for additive manufacturing. By drastically reducing the barrier to entry for professional 3D modeling, it not only accelerates existing processes but expands the universe of possible 3D printing users. In a market where iteration speed is crucial, this tool could become the accelerator that many companies need to stay competitive in the era of digital manufacturing. The distance between a paper idea and a physical object has never been shorter. ✨