Scientists Turn Lunar Dust into Material for Manufacturing Electronics

A group of researchers from Denmark, backed by the European Space Agency, has achieved a crucial breakthrough: proving that electronic parts can be made on the Moon. The study is based on modifying lunar regolith, the surface dust layer, to obtain substances that conduct electricity. This opens the door to creating electronic devices in situ, avoiding sending every piece from our planet. This progress is fundamental for planning autonomous expeditions and drastically cutting costs. 🚀

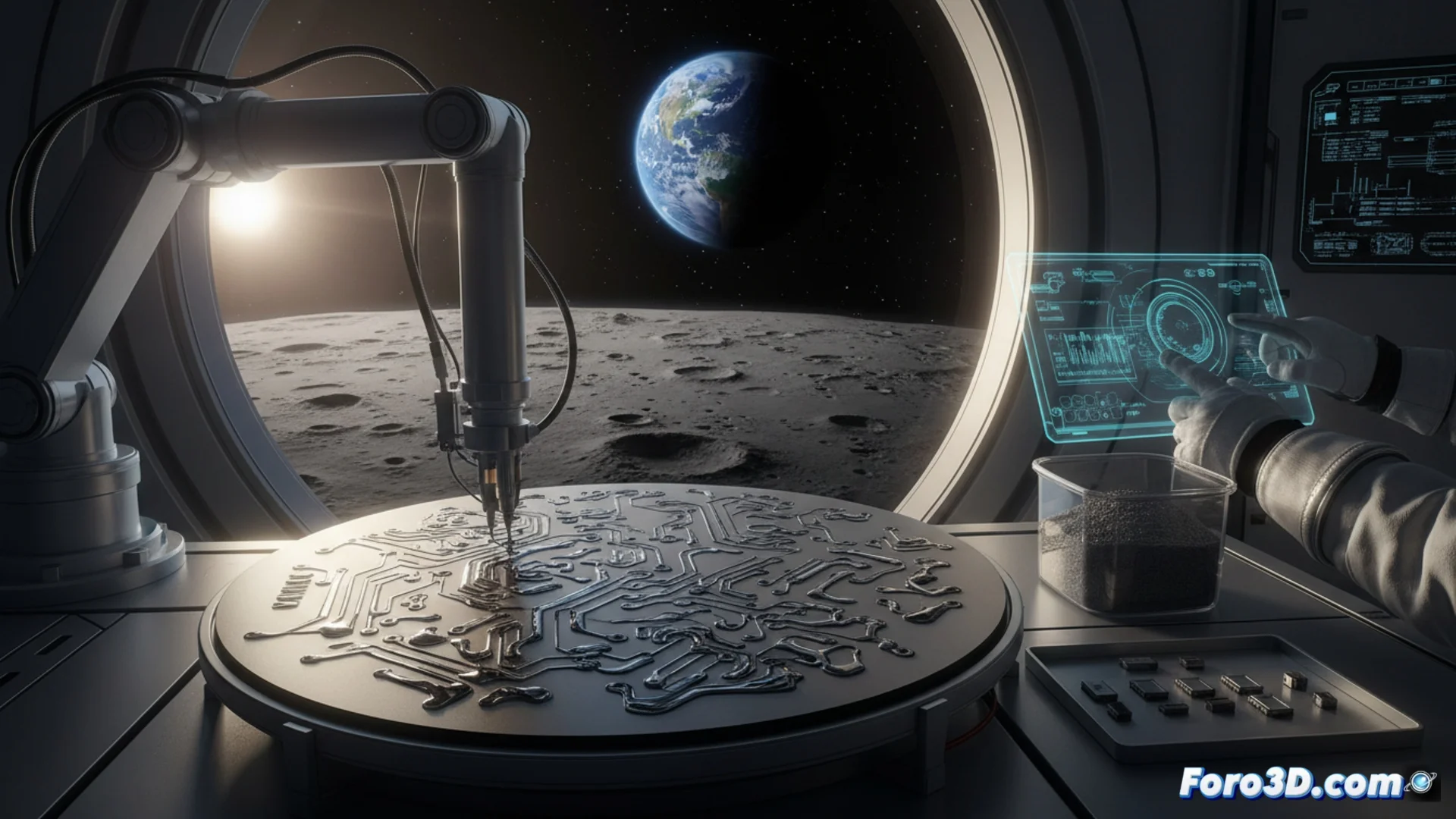

Transforming Lunar Soil into Inks for Printing Circuits

The method they propose processes regolith with low oxygen levels to transform it into conductive powders and inks. These products are ideal for use in additive manufacturing techniques and printed electronics, such as 3D printing. Thus, essential components like antennas, sensors, or segments of integrated circuits could be made directly on the Moon. The strategy aims to leverage locally available resources, a principle known as in-situ resource utilization.

Key Advantages of Manufacturing on the Moon:- Allows production of sensors and antennas with local materials.

- Enables the use of 3D printing and additive manufacturing techniques in space.

- Applies the concept of in-situ resource utilization (ISRU) to be self-sufficient.

By being able to produce what's necessary with lunar dust, future bases could be more autonomous and sustainable.

Reducing the Need to Send Everything from Earth

Making electronic components on our satellite represents a radical change in logistics for space exploration. Bringing any material from Earth involves enormous costs and limits what missions can do. By manufacturing what's required with lunar dust, future stations would gain autonomy and sustainability. This not only makes projects cheaper but also enables designing longer and more complex expeditions.

Impact on Future Exploration:- Drastically reduces transport costs from Earth.

- Increases the potential autonomy and duration of lunar missions.

- Facilitates the design of sustainable lunar bases with less external dependence.

A Future Where the Moon Prints Its Own Technology

This finding moves part of the industrial process to space. The next time you look at the Moon, consider that its dust could be printing the motherboard of a lunar computer, while on Earth we keep looking for the right power cable. This step brings closer the vision of self-sufficient space colonies that manufacture their tools with what they find around them. 🌕