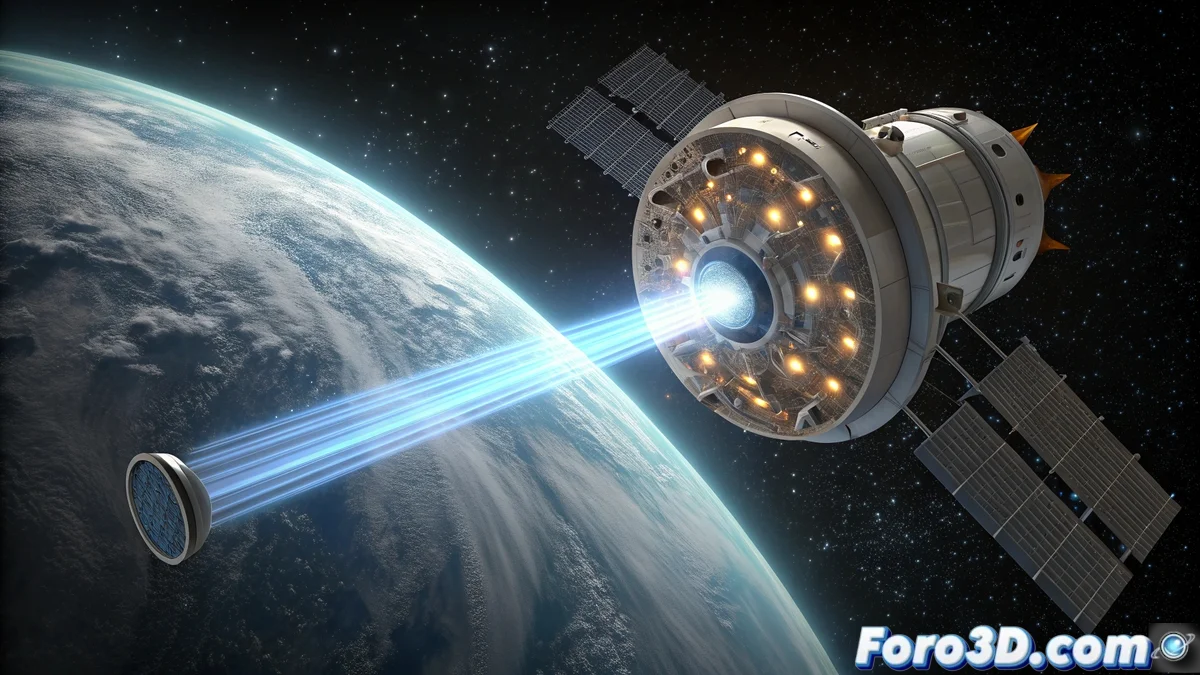

Satellite Propulsion with Nanotips and Naphthalene Revolutionizes the Aerospace Industry

A aerospace sector startup is radically transforming propulsion systems for small satellites through a completely innovative technology that integrates nanoscale structures with naphthalene propellant. This breakthrough represents a paradigm shift in the way satellites perform their orbital maneuvers 🛰️.

Field Emission Electric Propulsion Mechanism

The revolutionary system operates by applying extremely high voltages to the specialized nanotips, generating electric fields of sufficient intensity to vaporize and ionize the naphthalene stored in solid state. The resulting charged particles are controlled and accelerated by this field, producing precise directional thrust that enables high-accuracy orbital maneuvers.

Main features of the system:- Complete elimination of complex liquid fuels and their associated systems

- Significant reduction in storage requirements and structural weight

- More compact and lightweight satellite designs without compromising maneuverability

This technology represents the future of satellite propulsion, combining energy efficiency with unprecedented precision in orbital adjustments.

Competitive Advantages Over Conventional Systems

The nanotips with naphthalene technology far surpasses the limitations of traditional chemical thrusters and plasma systems, offering extraordinarily precise thrust control with notably reduced energy consumption. Naphthalene as the main propellant presents additional advantages such as its chemical stability, non-toxic nature, and significantly lower cost compared to conventional alternatives.

Key operational benefits:- Ability to perform frequent orbital adjustments without rapidly depleting resources

- Considerable extension of the operational life of satellites in constellations

- Improved reliability due to the absence of moving parts susceptible to failure

Impact on the Future of Space Missions

Satellites equipped with this technology will be able to maintain their orbital positions with millimeter precision while avoiding collisions with space debris, demonstrating that even seemingly conventional materials like naphthalene can achieve moments of technological glory in modern space exploration 🚀.