Innovation in Safety for Metal 3D Printing Post-Processing

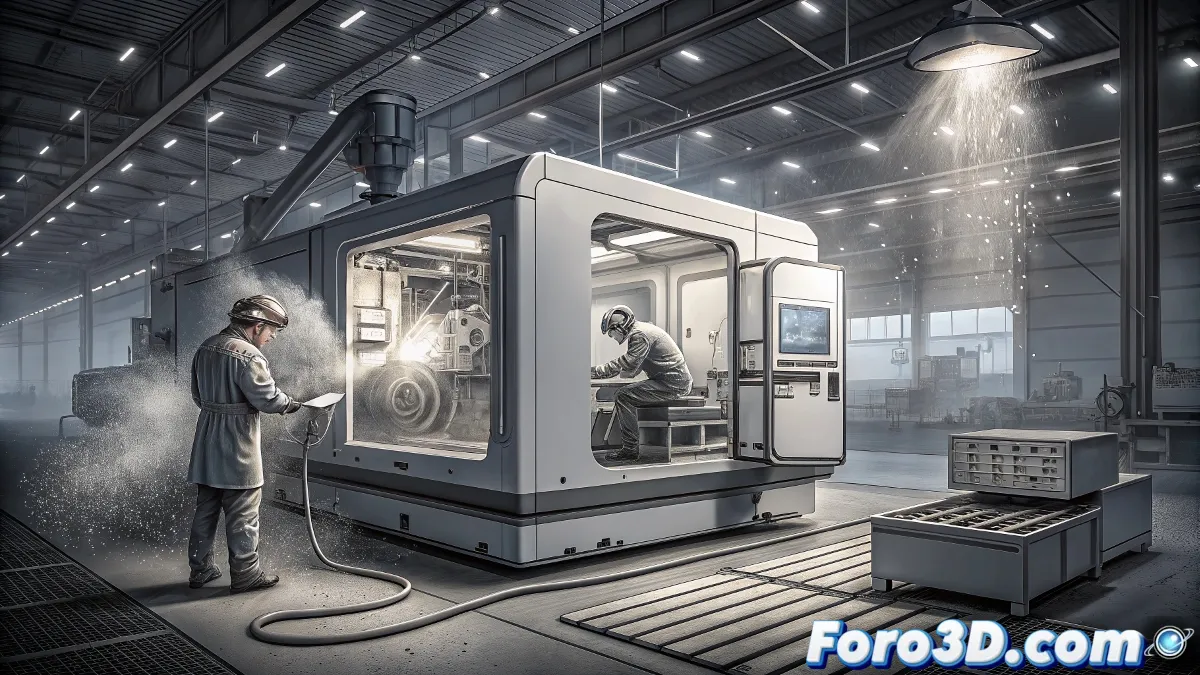

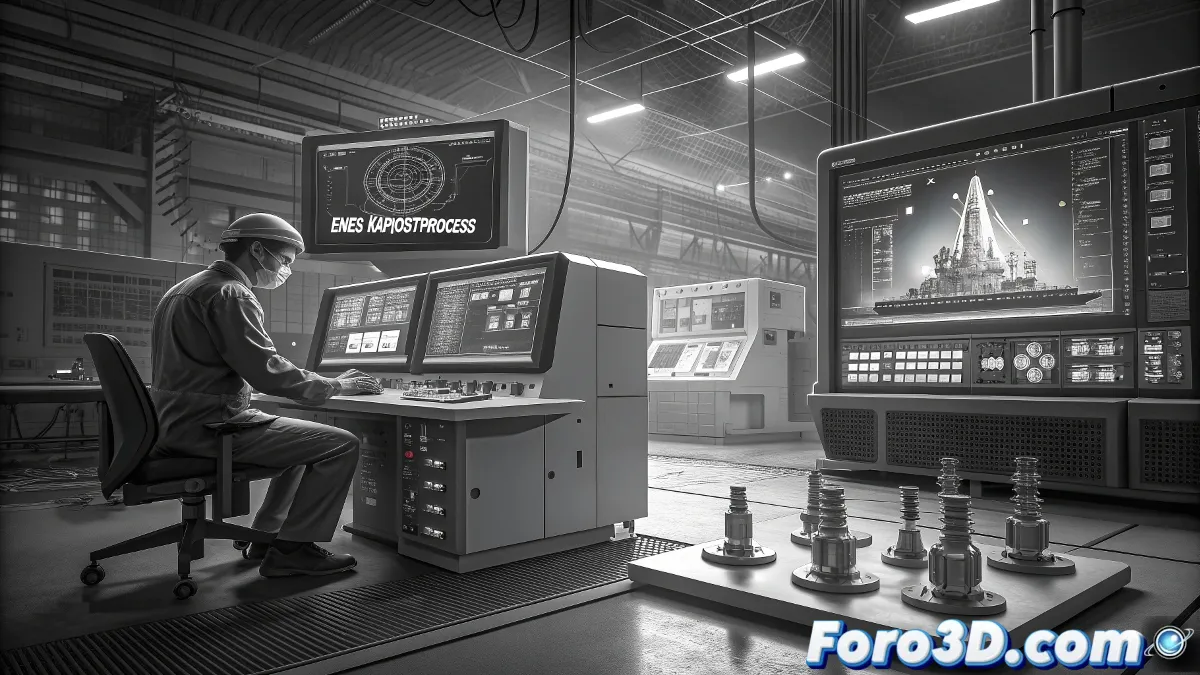

The additive manufacturing industry has taken a significant step forward in occupational safety with the implementation of the ENESKA postprocess system. This technological development, installed for the first time in the United Kingdom by Apex Additive Technologies, addresses one of the biggest challenges in the production of metal 3D printed parts: exposure to hazardous particles during finishing phases.

Key Features of the System

The solution developed by joke Technology offers several innovative advantages:

- Sealed 0.75 m² cabin with automatic locking system

- ATEX filtration for fine metal particles

- Operation with high-speed tools without additional PPE

- Continuous air quality monitoring

"Operator safety should not be a compromise in industrial additive manufacturing"

Benefits for the Industry

The adoption of this technology represents an advance in several critical aspects:

- Health protection: Eliminates exposure to hazardous metal dusts

- Operational efficiency: Reduces preparation and cleaning times

- Consistency: Maintains quality standards during post-processing

- Versatility: Compatible with various finishing operations

Trends in Additive Manufacturing

The sector continues to evolve with parallel developments such as:

- Multi-material printers for complex applications

- Greater precision in aerospace components

- Integrated solutions for series production

- Hybrid technologies combining additive and subtractive manufacturing

The pioneering implementation by Apex Additive Technologies sets an important precedent for the industry, demonstrating that it is possible to combine technological innovation with improved occupational safety standards. This approach will likely influence the decisions of other companies in the sector seeking to optimize their post-processing processes.