Roboze Certifies its Argo Printers for Ultem 9085 in the Japanese Market

The Italian company Roboze, specialized in manufacturing with 3D printing technology using high-performance polymers and composites, has achieved a key milestone. Its printer models Argo 500 Hyperspeed and Argo 1000 Hypermelt have received the Japanese Nannen-sei homologation for working with the material ULTEM 9085. This recognition confirms that these machines can handle this polymer reliably, whether in filament or pellet form, meeting the rigorous long-term durability standards required by the country. 🏭

The Nannen-sei Certification Opens Doors to the Japanese Industry

Obtaining the Nannen-sei seal is a crucial step for original equipment manufacturers and suppliers in Japan to integrate this technology. This official endorsement minimizes barriers to entering a market known for its extremely demanding quality criteria. Now, local industries can adopt additive manufacturing with ULTEM 9085 to produce end-use components with complete confidence.

Impact of the Certification:- Facilitates the adoption of 3D printing with high-performance materials by Japanese OEMs.

- Reduces technical and regulatory barriers to selling and implementing this technology in the country.

- Allows engineers to specify parts in ULTEM 9085 produced locally with full guarantees.

A small certification seal can open big doors in a market as meticulous as the Japanese one.

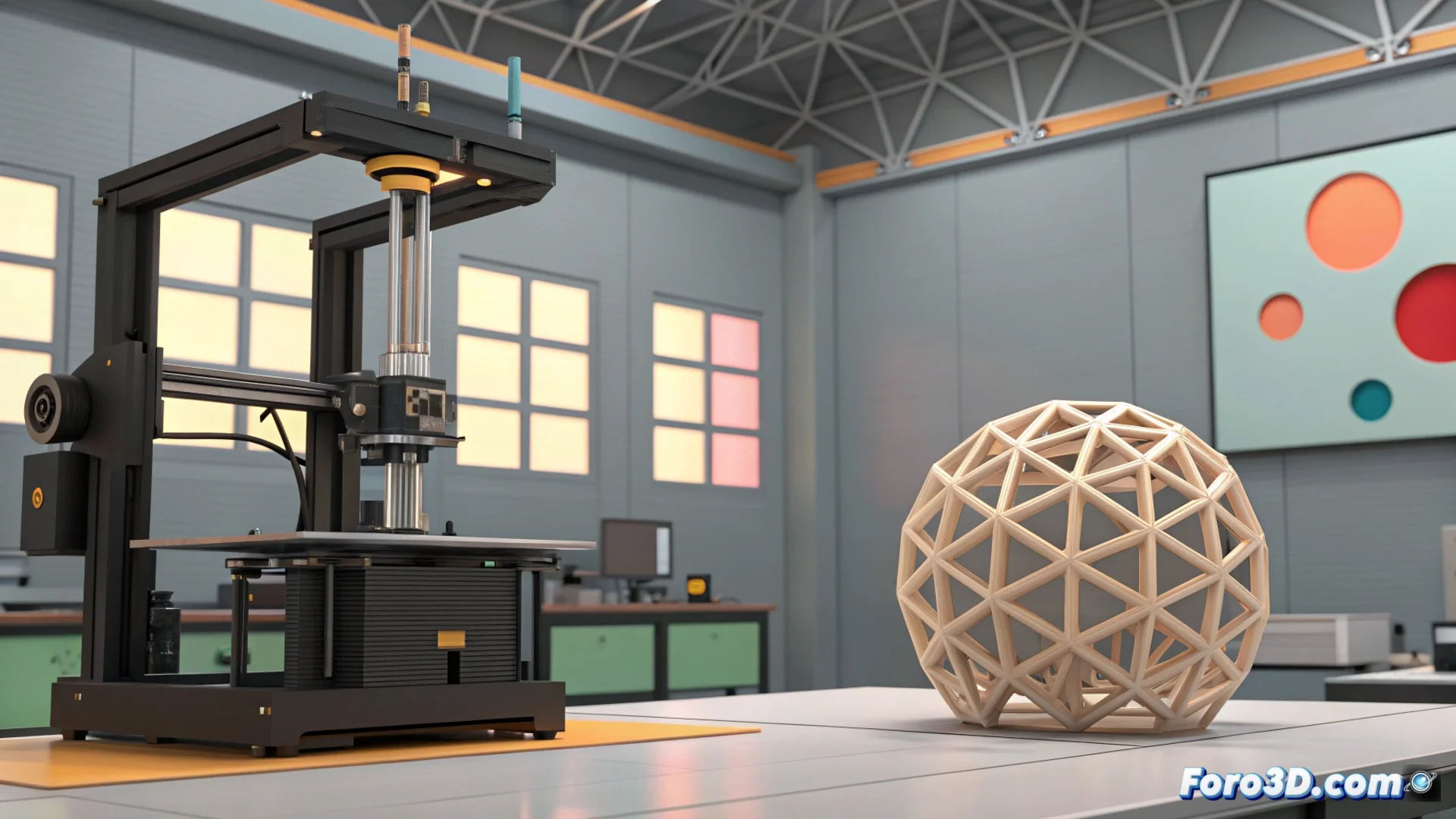

Argo Printers, Designed for Industrial Challenges

Roboze's Argo 500 and Argo 1000 platforms are built from the ground up to process advanced technical materials, such as polyetherimides. Each variant has a distinct focus to optimize industrial workflows.

Model Features:- The Hyperspeed version focuses on increasing print speed without sacrificing dimensional accuracy.

- The Hypermelt model is optimized for using polymers in pellet form, which can make higher-volume production more cost-effective.

- Both machines are prepared to operate reliably in demanding and continuous manufacturing environments.

Accelerating Innovation in Japanese Manufacturing

This achievement means that engineering projects in Japan no longer need to rely solely on traditional manufacturing methods or importing critical parts. The ability to locally produce end-use parts in ULTEM 9085 with certified equipment will speed up development times and offer greater flexibility. The Nannen-sei validation is not just a technical certificate, but a bridge connecting high-performance 3D printing technology with one of the world's most important industrial markets. 🚀