Titanium for the 99%: When Premium Becomes Accessible

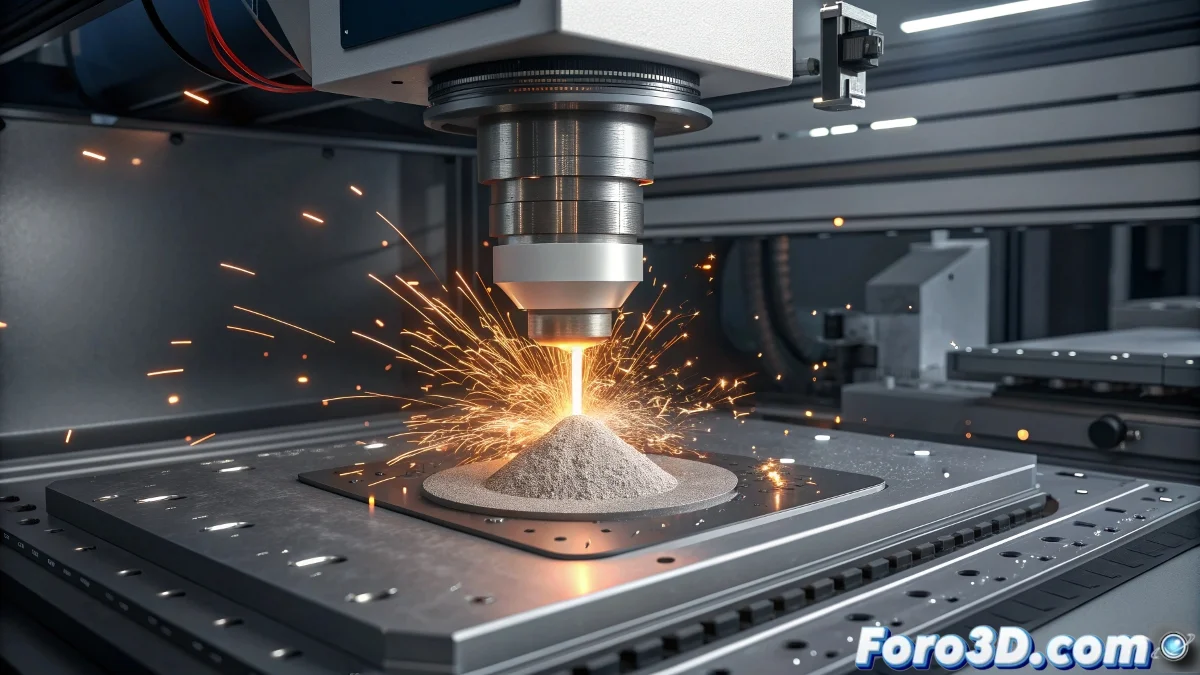

The Royal Melbourne Institute of Technology (RMIT) has achieved the impossible: making industrial-grade titanium stop costing an arm and a leg 💰🦴. Their new alloy optimized for 3D printing promises the same performance for a fraction of the price, because in the digital age even noble materials need a budget plan.

From Elite Material to Digital Commodity

This innovation combines redesigned metal powders with optimized printing parameters, achieving parts with that strength and lightness that make titanium famous, but without the usual economic headache. Now even your startup can afford luxuries that were previously only in private jets ✈️ (well, almost).

We have kept everything good about titanium - strength, biocompatibility, weight-to-strength ratio - but we have removed the prohibitive price — explains the lead researcher, probably next to a 3D printer that smells like the future.

Why This Is an Industrial Game-Changer

- Medical Implants: Customized prostheses within reach of more hospitals

- Aerospace: Lighter components without increasing costs

- Automotive: More energy-efficient engines and chassis

- Sustainability: Less material waste than traditional methods

The applications are so promising that even the space industry is taking notice. Because when you can print cost-effective titanium, even Mars seems a little closer 🚀.

So get ready: titanium is about to stop being that material everyone talks about but few use. The revolution of noble metals 2.0 has just begun... and it comes with a discount 💸✨.