Revolutionary Advance in 3D Printing for Self-Deploying Space Structures

A team of researchers from the University of Illinois has achieved a technological milestone by developing a specialized 3D printing system that fabricates components capable of deploying autonomously once in space orbit. This methodology integrates ultralight composite materials with geometric designs inspired by advanced folding principles, allowing structures to be transported in a compact format from Earth and expanded automatically in the cosmic vacuum. 🚀

Transformative Applications in Cosmic Exploration

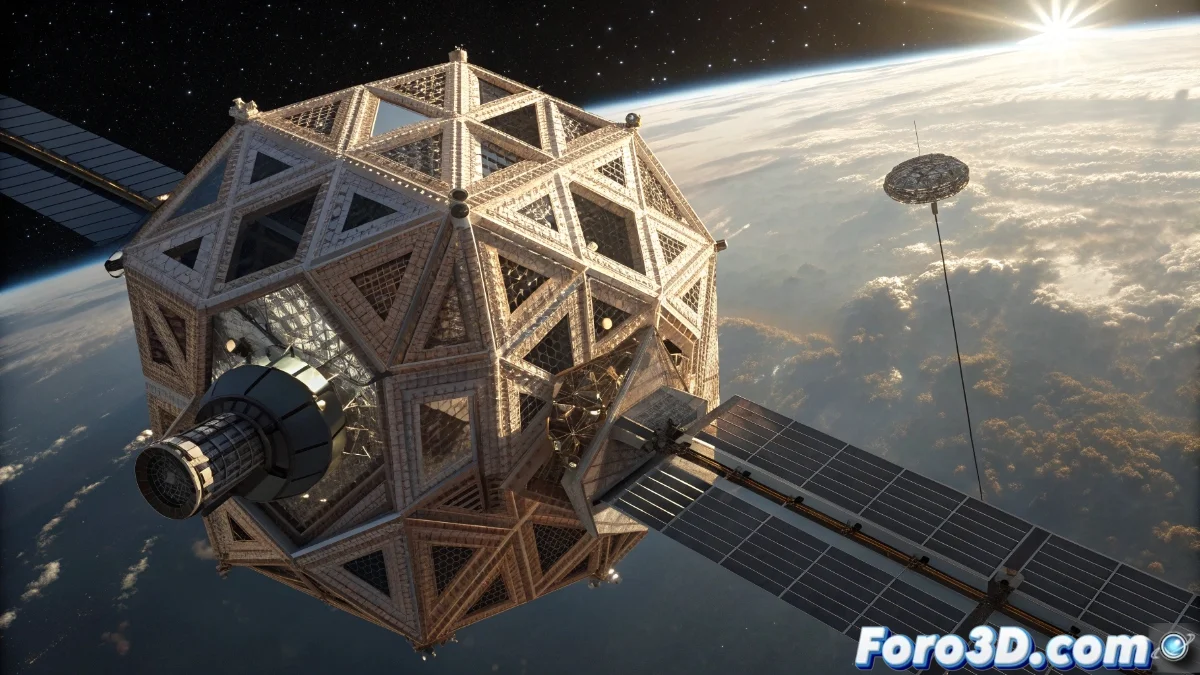

The potential implementations of this technology represent a qualitative leap for the aerospace industry, facilitating the creation of more efficient and versatile orbital infrastructure. The deployable components can be integrated into next-generation satellites, modular space stations, and even long-range missions to other planets, overcoming the traditional dimensional restrictions of launch vehicles.

Key Implementations:- Satellites with larger and more complex scientific instrumentation

- Transportable space habitats that self-assemble at their destination

- Modular orbital platforms for experimentation and research

The ability to create structures that expand in space allows us to design larger and more complex scientific instruments than current ones, overcoming the physical limitations of launch rockets.

Technical Innovations of the Manufacturing System

The developed methodology is characterized by its multidisciplinary approach that combines advanced composite materials with geometries inspired by traditional origami. These materials maintain an exceptional relationship between structural strength and minimal weight, while allowing for extremely compact folding configurations. The high-precision 3D printing process ensures the millimeter-accurate manufacturing of joints and deployment mechanisms, completely eliminating the need for manual intervention during orbital assembly.

Highlighted Technical Features:- Composite materials with shape memory and optimized structural strength

- Thermal or mechanical activation mechanisms for controlled deployment

- Foldable geometries that maximize storage space during launch

Future of Space Infrastructure

This disruptive technology not only significantly optimizes the use of available space in launch capsules but also drastically reduces the operational costs associated with space transport. Imagine a future where we can send complete space station components, scientific instruments, and even specialized furniture that self-assemble upon arrival at their destination, making traditional assembly instructions unnecessary. 🌌