Revolution in Automotive Safety through European Additive Manufacturing

A European technology consortium is radically transforming vehicle safety paradigms through the implementation of advanced additive manufacturing technologies. This strategic collaboration brings together the continent's leading automotive manufacturers with specialized research centers 🚗.

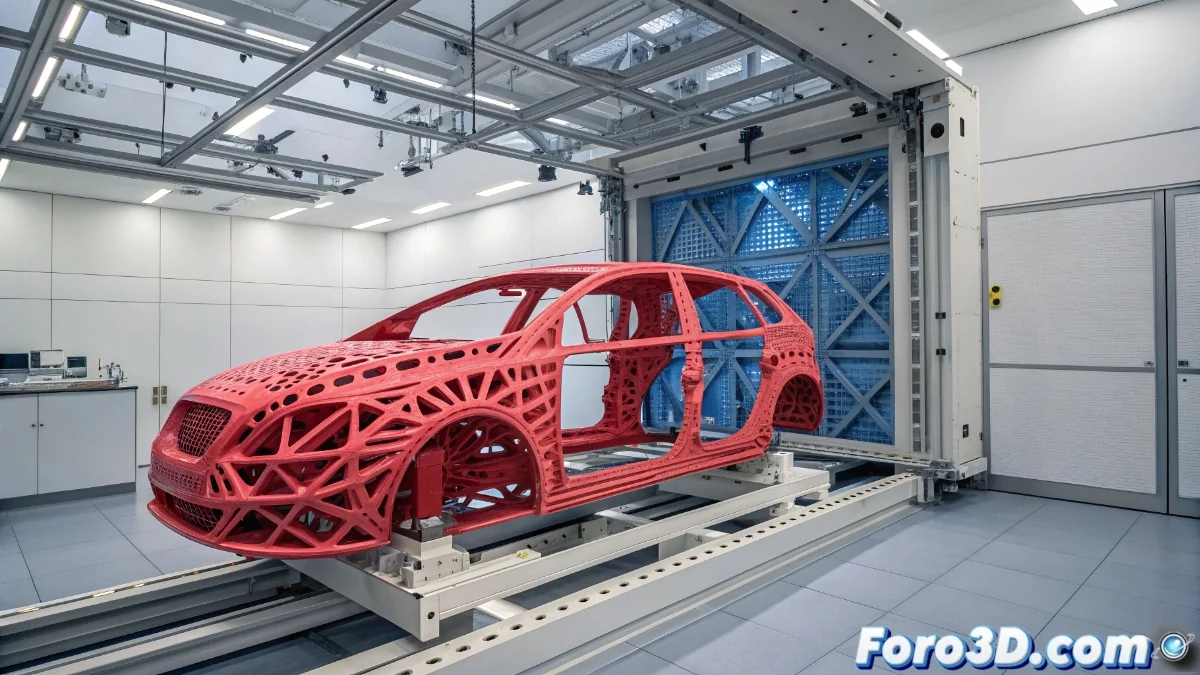

Transformative Advantages of 3D Printing in Safety

Additive manufacturing enables the creation of components with optimized internal geometries that were technically impossible with traditional production methods. This design freedom translates into energy-absorbing structures that significantly outperform conventional parts 💥.

Key benefits of the technology:- Structural weight reduction while maintaining integrity in impacts

- Customization capability according to specific vehicle models

- Accelerated design iteration through rapid prototyping

Engineers can fail faster and with better style, creating prototypes that seem straight out of science fiction but must survive the real world full of potholes and distracted drivers.

Innovative Materials and Validation Processes

The project employs specialized metal alloys and polymer composites developed exclusively for high-impact applications. These materials demonstrate enhanced mechanical properties and predictable behavior under extreme stress conditions 🔬.

Advances in testing and certification:- Virtual collision simulations with high predictive accuracy

- Physical tests validating compliance with European regulations

- Verified better performance in side and frontal impacts

Impact on the Future of the Automotive Industry

This technological revolution is not only shortening the development cycles of critical components but also establishing new standards of excellence in protection for occupants and pedestrians. The ability to create optimized internal structures represents a significant advance toward safer and more efficient vehicles 🌟.