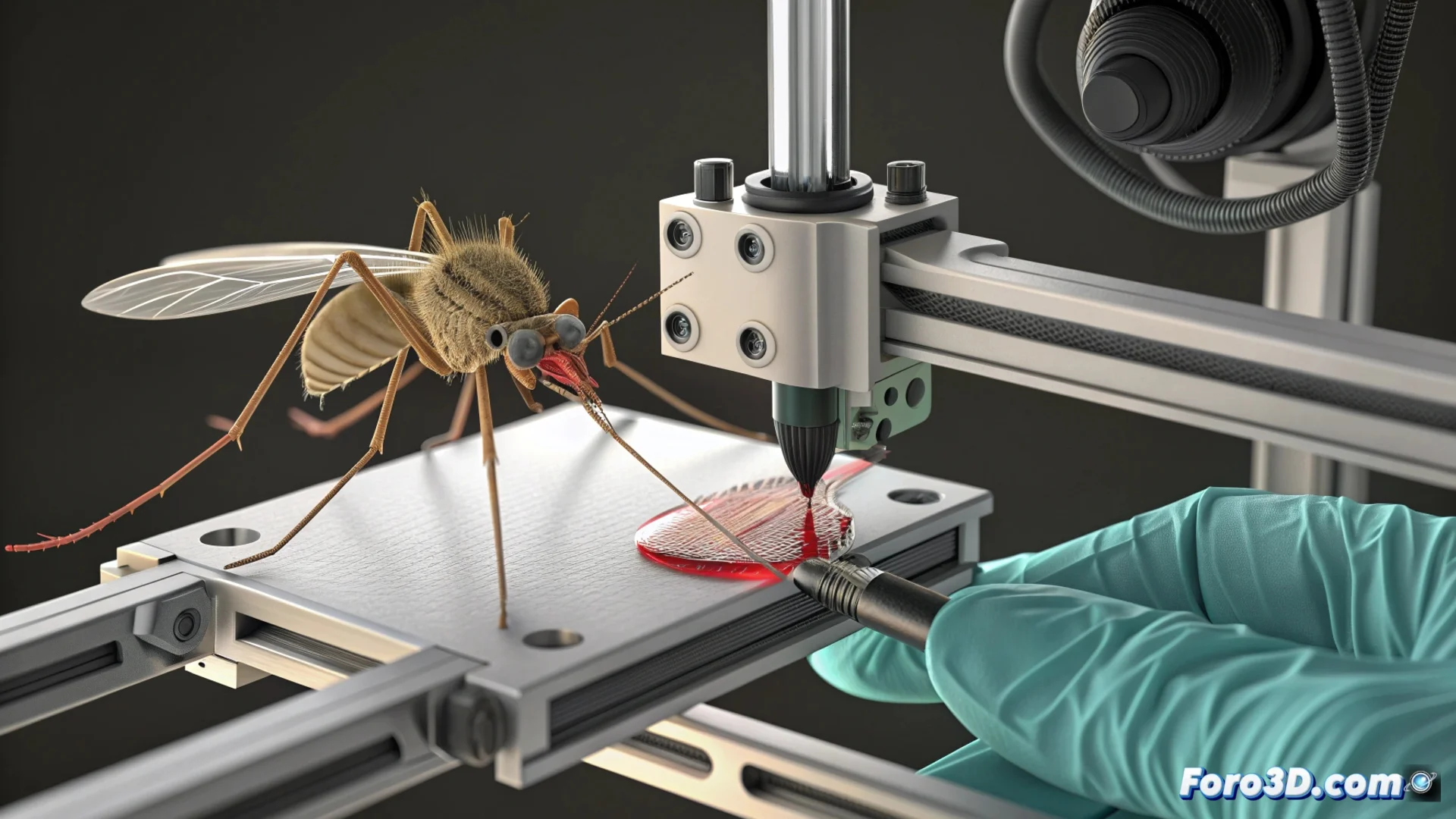

Researchers Use Mosquito Feeding Tubes as Ultrafine 3D Printing Nozzles

The pursuit of extreme precision in additive manufacturing has led scientists to draw inspiration from nature. A team is now exploring a radical approach: using mosquitoes' mouthparts, their stylets, to function as 3D printing nozzles. These natural tubes, with diameters of just microns, represent an ingenious solution for manipulating materials at a previously unattainable scale. 🦟

Leveraging Complex Natural Structures for Microfabrication

The process focuses on the mosquito stylets, which are hollow and extraordinarily thin structures that the insect uses to feed. The researchers prepare these biological components and integrate them into custom 3D printing systems. This innovative approach produces nozzles with significantly smaller internal diameters than those achievable with conventional techniques like machining metal or drawing glass.

Key advantages of using biological stylets:- Ultrafine diameter: Allows manipulation and extrusion of tiny volumes of liquid with unprecedented control.

- Preexisting structure: Leverages a complex and efficient geometry developed by evolution, difficult to replicate artificially.

- Simplifies the process: Reduces the need to develop ultra-complex manufacturing techniques to produce nozzles at this scale.

Perhaps the next time a mosquito bites you, instead of being annoyed, you'll think that its work tool could drive the next revolution in microfabrication.

Printing with Resolution That Redefines Limits

By implementing these biological nozzles, materials can be processed and deposited with submicroscopic precision. This leap in resolution is not just incremental; it opens new frontiers in high-tech fields where size is critical.

Potential applications of this technique:- Microelectronics: For assembling extremely small electronic components and creating microscale circuits.

- Biomedicine and tissue engineering: For building complex cellular scaffolds with precise architecture that mimics natural biological structures.

- Materials research: For developing and testing new compounds by depositing patterns at nanoscale resolution