Researchers Modify 3D Printing to Optimize Nuclear Fuel

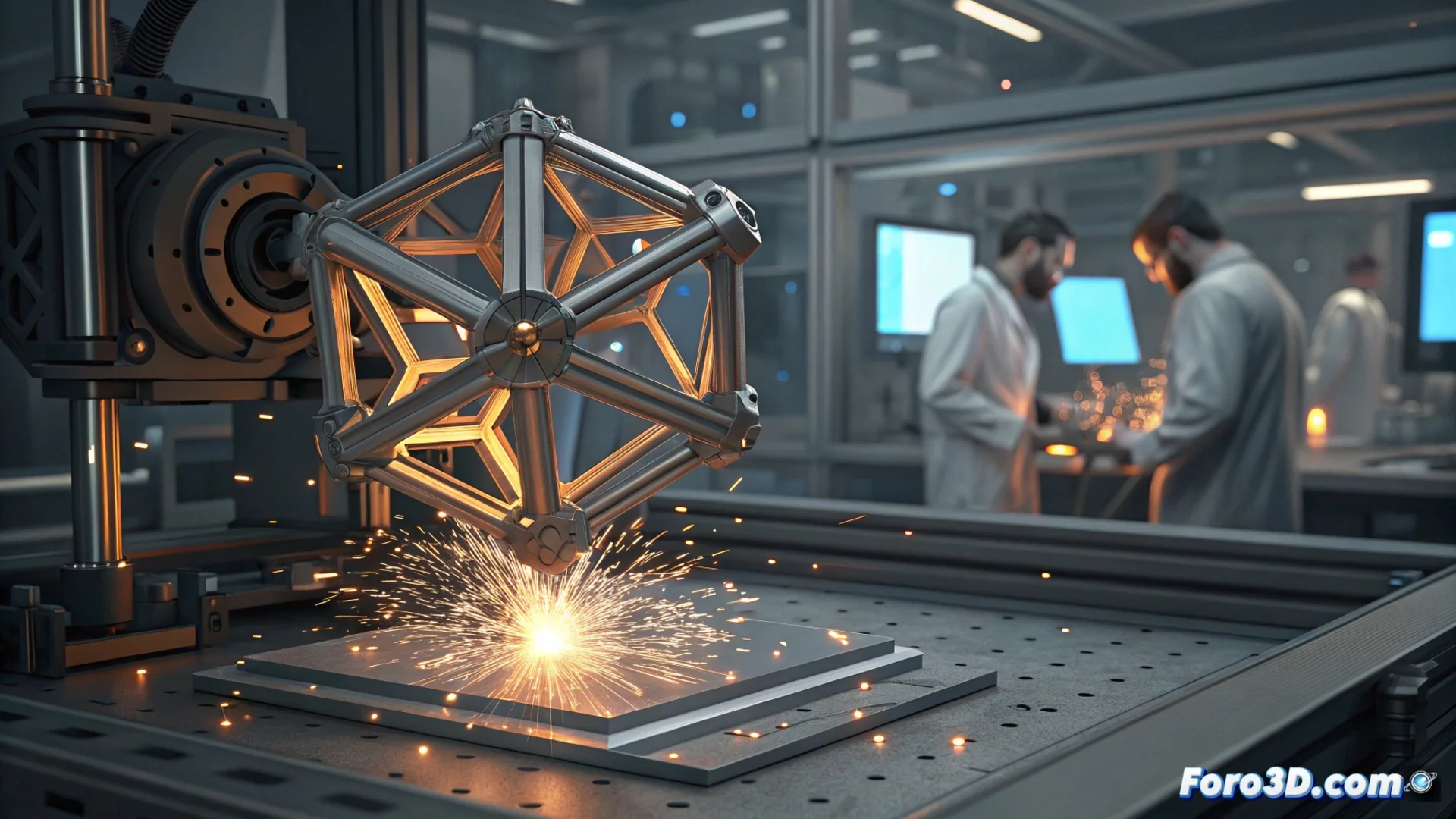

A team from Kennesaw State University is changing how components for nuclear reactors are manufactured. Their goal is to use additive manufacturing to create fuels with superior performance, which could transform the future of atomic energy. 🔬⚛️

Controlling the Microstructure is Key

The study focuses on how varying 3D printing parameters, such as laser power or fusion path, alters the internal arrangement of the material. By mastering this process, scientists can design fuels with specific porosity and grain distribution. These characteristics improve thermal conductivity and the ability to withstand radiation, key factors for managing heat and fission byproducts within the reactor core.

Key Parameters Being Investigated:- Laser Speed and Power: Determine how the material melts and solidifies, affecting density and grain formation.

- Scan Pattern: The path followed by the laser influences the homogeneity and internal stresses of the part.

- Layer-by-Layer Manufacturing Strategy: Allows for controlled porosity and internal channels that are impossible with conventional methods.

The design flexibility offered by 3D printing allows us to completely rethink the internal architecture of nuclear materials, something traditional metallurgy cannot do.

Implications for the Nuclear Industry

If this approach succeeds, the impact would be significant, especially for light water reactors, which are the backbone of current nuclear generation. More efficient and durable fuel would extend operational cycles, reducing the frequency of reactor shutdowns for refueling.

Potential Benefits of This Innovation:- Greater Safety: A material that better manages heat and radiation increases the safety margins of operation.

- Reduction in Operating Costs: Fewer refueling shutdowns mean more time generating electricity and lower maintenance expenses.

- Fewer Wastes Generated: By burning the fuel more completely and for longer, the volume of radioactive waste to be managed is reduced.

A Step Toward More Adaptable Nuclear Energy

This research demonstrates that 3D printing is not just a tool for prototypes, but a technology capable of solving high-level engineering challenges. By enabling unprecedented control over the material's microstructure, it opens the door to designing fuels tailored to specific needs, promoting more sustainable and economical nuclear energy. The scope of additive manufacturing continues to expand, from everyday objects to the very heart of energy production. 🚀