Replique Expands Its Global Alliance with Alstom to Optimize Spare Parts

The digital platform Replique has announced that it is expanding its global collaboration agreement with the transportation corporation Alstom. This expansion enables a greater number of Alstom divisions worldwide to utilize Replique's on-demand additive manufacturing network. The central purpose is to digitally transform and make the component supply chain more efficient, reducing material inventories and lead times. 🚆

Transforming Physical Inventory into Digital

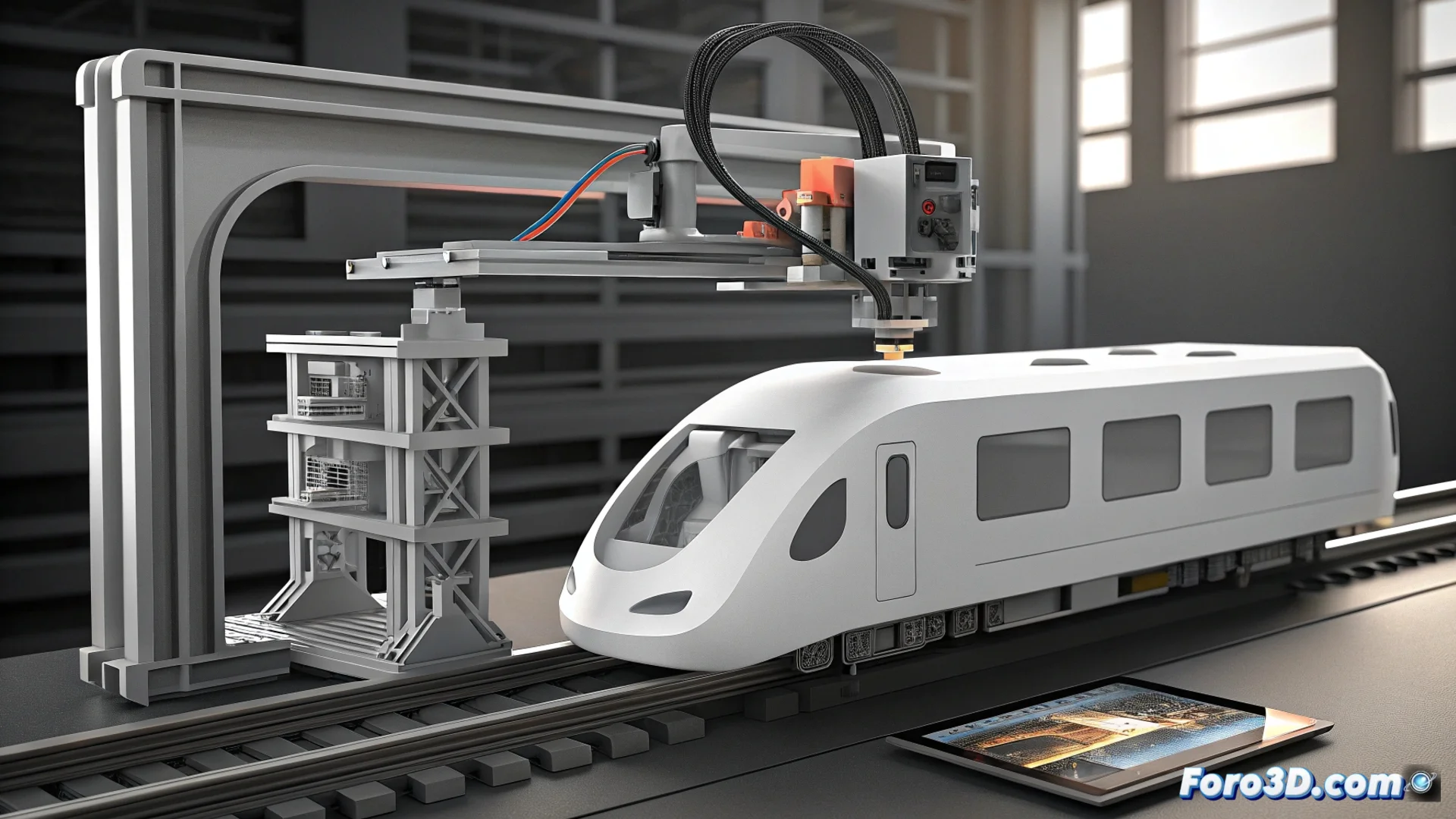

Replique operates on a digital warehouse concept. Instead of physically storing thousands of components, Alstom uploads the 3D designs of the parts to the secure platform. When a maintenance center needs a component, it requests it, and Replique produces it locally and in real time, leveraging its global network of specialized 3D printing partners. This method eliminates the need for large material reserves, reduces the risk of parts becoming obsolete, and shortens delivery times from several weeks to just days.

Key advantages of the digital model:- Eliminate the need to store large quantities of physical parts.

- Reduce the risk of stored components becoming obsolete.

- Shorten delivery times from weeks to just a few days.

The collaboration, which began in 2022, already enables on-demand production of parts for high-speed trains, trams, and metros.

Application to the Global Train Fleet

Expanding this agreement means that more Alstom business units in different countries will be able to use the platform to manage their spare parts on a global scale. This helps ensure the availability of critical components, even for older train models, and keeps the fleet operational more effectively with fewer unplanned downtimes.

Areas of implementation:- Manufacture parts on demand for high-speed trains.

- Produce components for trams and metro systems.

- Manage spare parts for fleets worldwide in a centralized manner.

A Future with Fewer Disruptions

In summary, this strategic alliance seeks to revolutionize how spare parts are managed in the rail transport sector. By digitizing inventories and manufacturing locally on demand, not only are resources optimized, but agility and resilience are gained. So, if your train is delayed, the cause might no longer be searching for a part in a remote warehouse, but it could be printing in a nearby facility. 🛠️