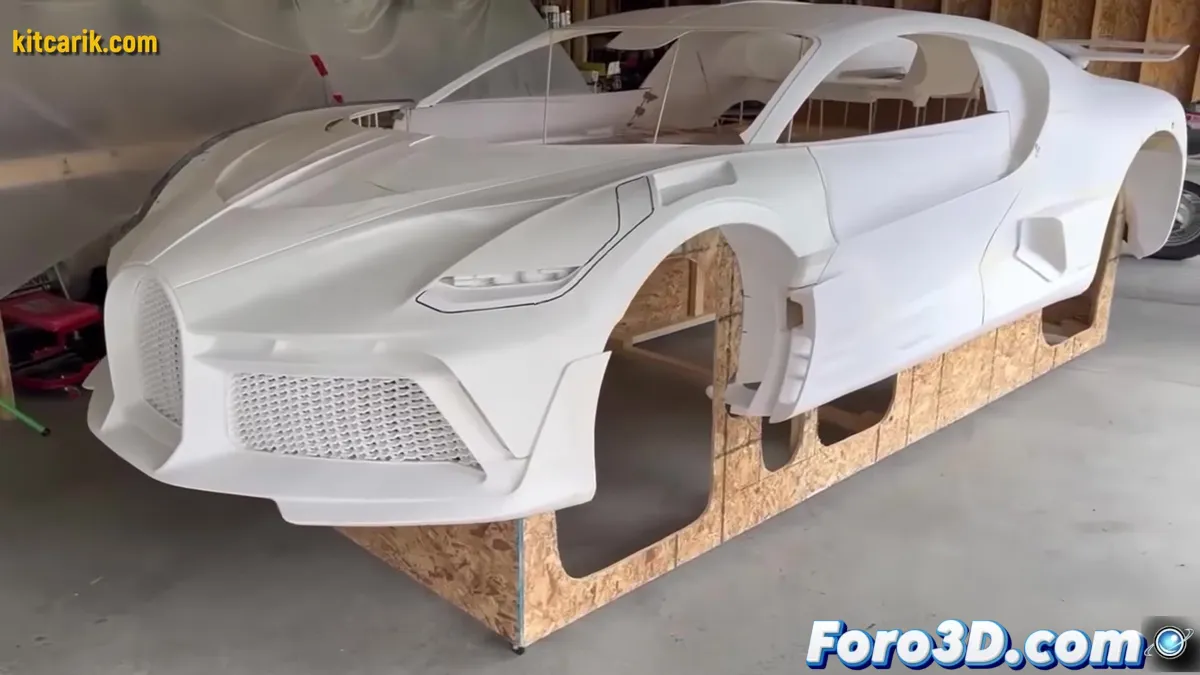

A Canadian enthusiast has managed to reproduce a high-end vehicle using additive manufacturing technology in a home environment. The digital plans were obtained through the KitCar channel, run by brothers Rustem and Aidar, demonstrating how accessible tools enable complex automotive projects.

Construction Methodology

The process involved manufacturing the different body components separately using 3D printing. Subsequently, the parts were assembled using high-strength adhesives. To ensure durability without compromising the design, fiberglass reinforcement was applied, faithfully capturing the aerodynamic elements of the original vehicle.

This approach allows for professional results with non-industrial equipment

Similar Initiatives on the KitCar Channel

The platform has recorded various comparable projects, including:

- Mercedes 300SL with characteristic opening system

- Version of the Lamborghini Huracán sports car

- Full-scale recreation of the animated character Lightning McQueen

The creators emphasize that perseverance is the determining factor more than specialized technical training.

Transformation in the Automotive Sector

While the manufacturing of isolated components has become normalized, the complete production of automobiles remains uncommon among individuals. This innovation is redefining traditional boundaries, facilitating access to exclusive models that were previously prohibitive.

Development Perspectives

This case illustrates the growing potential of personalized manufacturing. Continuous improvements in:

- Printing accuracy

- Material variety

- Equipment availability

Are enabling more enthusiasts to materialize their ideas, opening new possibilities in the world of motorsport.