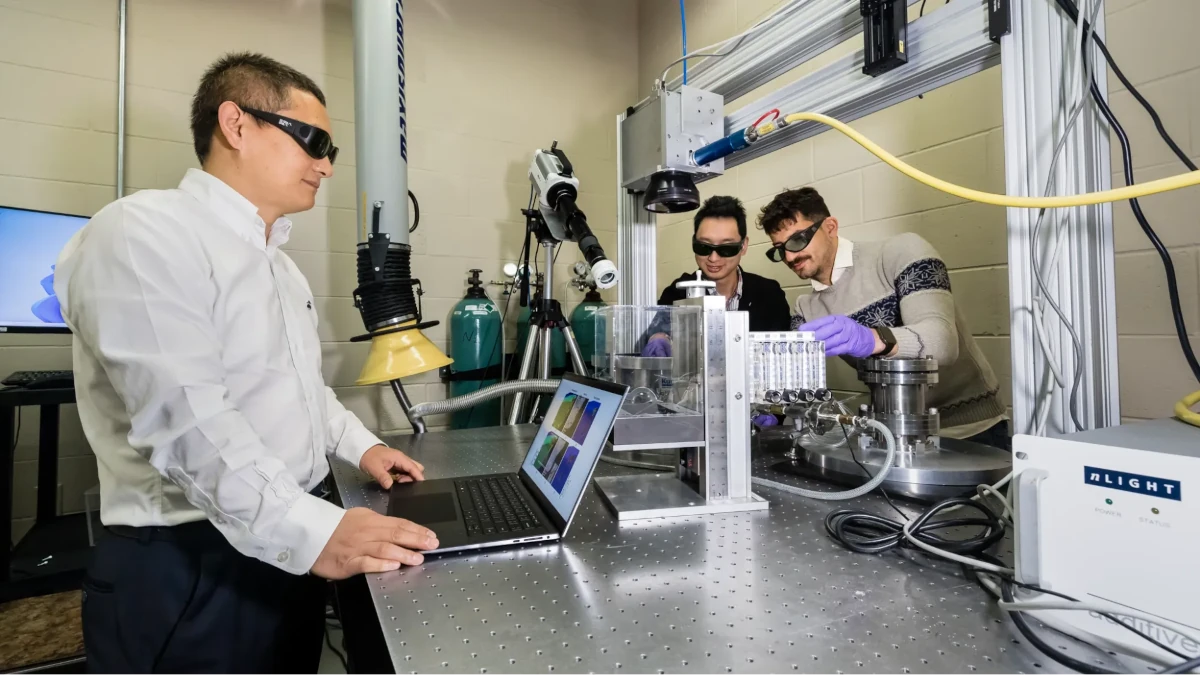

A team of engineers from the University of Wisconsin-Madison, led by Professor Lianyi Chen, has achieved a significant breakthrough in 3D metal printing. This new technique, which has applications in sectors such as aerospace, medicine, and energy, promises to reduce three common defects in printed parts: pores (holes), rough surfaces, and large spatters. Additionally, this improvement also allows for producing parts more quickly and efficiently.

The innovative technique to improve the quality of printed parts

The secret to this improvement lies in an innovative ring-shaped laser, instead of the traditional spot laser. This laser has the ability to better penetrate the material without causing instability in the printing process, allowing for thicker layers to be printed and, at the same time, increasing productivity. This innovation makes 3D metal printing more reliable and efficient, especially in critical applications where quality is essential.

Real-time monitoring to avoid defects

To ensure the quality of the parts, the researchers used a high-speed X-ray imaging system, which allowed them to observe how the material behaved while being printed. Thanks to this real-time observation, the team was able to identify the exact conditions that prevented the most common defects, such as pores or rough surfaces.

"This breakthrough allows for printing high-quality metal parts at much higher speeds, opening up new possibilities for critical industrial applications."

Impact of the new technique on the industry

The improvement in 3D metal printing is crucial for sectors where reliability and precision are essential. The manufacturing of complex metal parts is one of the greatest advantages of this technology, but quality defects have limited its use. Now, with the new technique, not only are defects reduced, but production speed is also improved, making this technology an even more attractive option for aviation, medicine, and energy.

Benefits for the manufacturing of critical metal parts

- Reduction of defects such as pores, rough surfaces, and large spatters.

- Higher production speed without compromising quality.

- Greater reliability and precision in critical parts.

- Opening of new opportunities for manufacturing in sectors such as aviation and medicine.

This breakthrough has the potential to transform 3D metal printing, allowing it to be used more widely in industries where reliability is essential, and making printed metal parts a viable and safe option for critical applications.