Creaform HandySCAN Software: Brain of the Portable 3D Scanner

The Creaform HandySCAN application constitutes the operational core of the portable three-dimensional scanning system developed by the namesake company. This specialized software acts as the intelligent control center that directs the device, processes the captured information, and generates high-fidelity three-dimensional digital representations. Its intuitive interface accompanies the operator throughout the entire digitization chain, from initial adjustments to obtaining the final ready-to-use model. 🧠

Fundamental Technical Capabilities

The program incorporates advanced functions that ensure metrological precision in every project. It allows equipment calibration before starting any capture, verifying that all measurements meet the required standards. During data acquisition, it displays the point cloud being generated in real time, enabling immediate corrections in areas with resolution or coverage deficiencies. Additionally, it integrates utilities for debugging and organizing information, combining multiple scans, and adding surface features such as textures or colors to the resulting models.

Main Tools Included:- Automatic calibration system that ensures accuracy in measurements

- Real-time visualization of the point cloud during scanning

- Cleaning, alignment, and fusion utilities for multiple captures

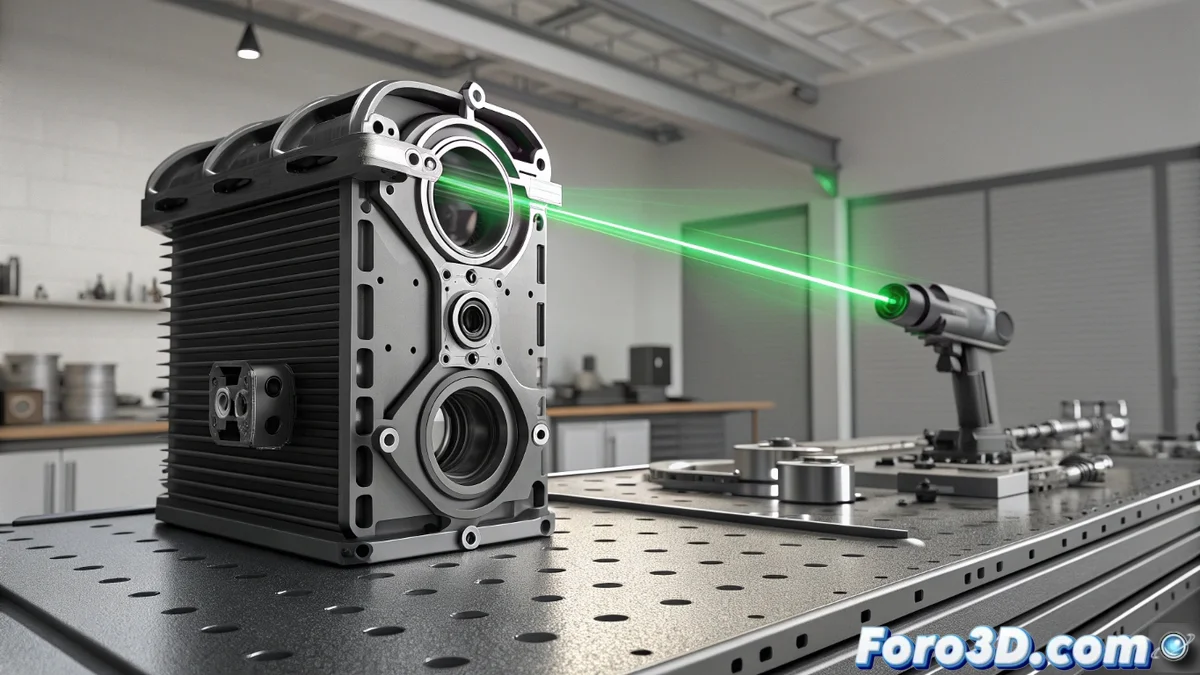

The millimeter precision of the HandySCAN software revolutionizes dimensional control processes in demanding industrial environments

Implementation in Various Industrial Sectors

This software solution is indispensable in industries where dimensional accuracy is critical, such as the automotive, aerospace, and manufacturing sectors. It is used to examine components and compare them with their theoretical designs, identifying deviations that could compromise the functioning of the finished product. It also facilitates the digitization of physical objects lacking technical documentation, producing editable and reproducible CAD models. Its adaptability makes it equally valuable for cultural heritage preservation, where sculptures or historical artifacts are digitized for analysis and digital preservation.

Highlighted Applications:- Metrological inspection and quality control in industrial production

- Reverse engineering of parts without technical documentation

- Digitization of cultural assets for study and conservation

Reflections on User Experience

Although it considerably simplifies workflows, it sometimes creates the sensation that the scanner demonstrates greater operational intelligence than the human operator, particularly when it detects imperfections that had gone unnoticed during visual inspection. This feature underscores the assistive potential of the software in processes where meticulousness is fundamental. 🔍