The Art of Making the Impossible Possible

PVA represents an elegant solution to one of the greatest challenges in 3D printing: supports for complex geometries. This water-soluble material acts as a temporary scaffold that literally disappears in water, releasing parts with internal cavities, extreme overhangs, and structures that would be unthinkable with traditional methods. Its ability to dissolve completely without leaving a trace makes it the perfect ally for designers exploring the limits of what can be printed.

The magic of PVA lies in its chemical nature that responds to water like a magic key. Unlike conventional supports that require tools and infinite patience to remove, those structured with PVA simply disintegrate when submerged in warm water. This feature revolutionizes the world of printed jewelry, medical prototypes, and components with internal channels where manual access is impossible.

Technical Properties of PVA

- Complete solubility in water without affecting other materials

- Perfect compatibility with PLA in dual extrusion systems

- Printing temperature similar to PLA between 185°C and 200°C

- High sensitivity to ambient humidity that requires careful storage

The Challenge of Extreme Hygroscopicity

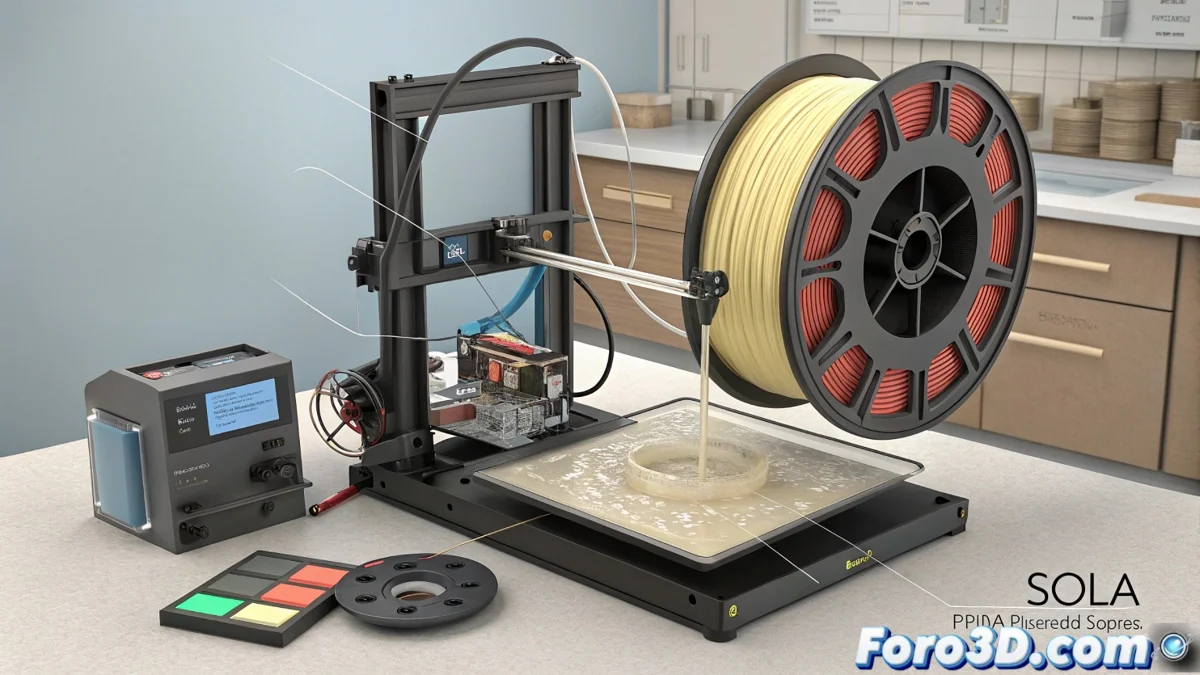

The main difficulty with PVA lies in its avidity to absorb moisture from the environment. This material can become unprintable in a matter of hours if exposed to air without protection, developing bubbles, clogs, and poor finishes. Experienced users store the filament in airtight containers with powerful desiccants and frequently use active dry boxes during printing itself to keep it in optimal conditions.

PVA transforms geometric complexity into a simple process of controlled dissolution

Printing with PVA requires precise setup in dual extrusion systems. Calibration between nozzles must be perfect to ensure a clean interface between the main material and the supports. Retraction parameters are particularly critical to avoid strings and cross-contamination between materials. When set up correctly, the result is parts with perfect surfaces in areas that would normally be damaged by conventional supports.

Applications Where PVA is Indispensable

- Geometries with inaccessible internal cavities

- Jewelry structures with intricate and interlocked details

- Medical and dental prototypes that require perfect surfaces

- Mechanical components with complex internal channels and passages

The dissolution process transforms the post-printing experience into an almost therapeutic ritual where the support structures progressively disintegrate, revealing the final geometry in all its splendor. For projects that demand the maximum in surface quality and geometric complexity, PVA remains the most elegant and effective solution available in the 3D printing market. 💧

Using PVA is like having a magic assistant that builds invisible scaffolds: it does all the dirty work and then disappears without a trace, although sometimes it melts faster than an ice cream in summer if you don't store it correctly. 🍦

You can see this product and similar ones in the: store