When Ceramics Leave Art to Conquer Industry

The collaboration between Prodways and HRL Laboratories is redefining what's possible in the world of ceramic 3D printing, proving that this ancestral material has much to offer to the industry of the future. The advances achieved combine the structural elegance of traditional ceramics with the millimeter precision of modern additive manufacturing. 🔬 The result is a qualitative leap in both resolution and mechanical strength, enabling the creation of parts that challenge the limitations of conventional manufacturing methods. Sectors like aerospace and biomedical are watching closely how this technology could solve design problems that have been awaiting solutions for years.

The Art of Printing the Apparently Impossible

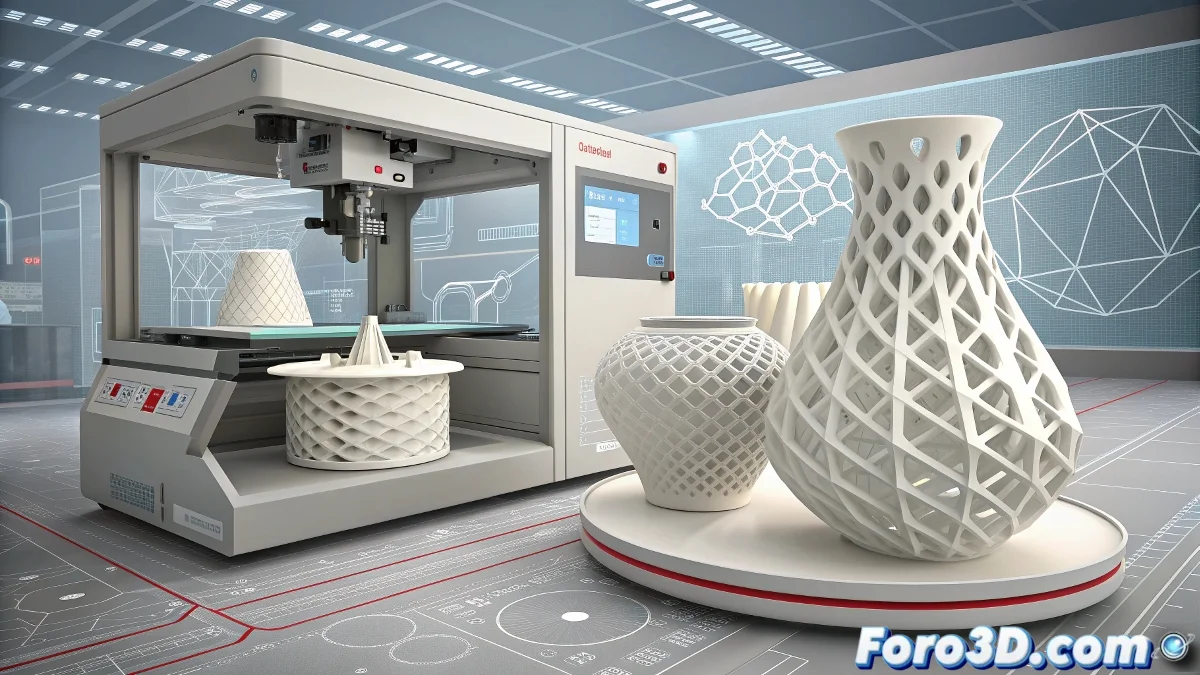

What makes this technology special is not just printing ceramics, but doing so with a level of detail that rivals the most refined artisanal techniques. The high resolution achieved allows for the creation of lattice structures, internal channels, and organic geometries that would be unfeasible with any other method. 💎 The magic lies in the development of ceramics specifically formulated for 3D printing, combined with optimized sintering processes that preserve the finest details while ensuring structural integrity. It's as if they taught ceramics to dance ballet instead of just walking.

Revolutionary Technical Features:- Resolution allowing details under 100 microns

- Mechanical strength comparable to traditionally molded parts

- Capability for complex under and over cantilever geometries

- Dimensional stability during the sintering process

Applications That Justify Industrial Enthusiasm

In the aerospace sector, this technology enables the creation of turbine components with internal cooling systems that improve thermal efficiency. In automotive, it enables ceramic sensors integrated into complex structures that withstand high temperatures and vibrations. 🏥 The biomedical field may be the most exciting, with the ability to produce customized implants with controlled porosity that favor osseointegration. Each sector finds in this printed ceramic a solution to specific problems that previously lacked a satisfactory response.

The Perfect Alliance: Industrial Expertise Meets Cutting-Edge Research

The collaboration between Prodways, with its knowledge in industrial 3D printing systems, and HRL Laboratories, with its expertise in advanced materials science, represents a textbook case of how synergy between companies can accelerate innovation. 🤝 While Prodways brings its UV light-based printing technology and advanced materials, HRL contributes its knowledge in technical ceramics and post-processing methods. The result is a complete technological ecosystem that goes from design to the final part, passing through all the critical intermediate stages for industrial success.

Competitive Advantages of This Collaboration:- Combination of manufacturing and materials science know-how

- Joint development of materials and process parameters

- Accelerated industrial validation through rigorous testing

- Focus on real applications with specific needs

Not All Perfect Ceramics: Pending Challenges

Despite significant advances, the technology still faces important barriers to mass adoption. The cost of specialized equipment and premium materials remains prohibitive for many commercial applications. ⚠️ Additionally, scalability for series production presents considerable technical challenges, especially regarding cycle times and reproducibility between batches. The learning curve for operators is also significant, requiring knowledge of both 3D printing and traditional ceramic processing.

The Future: Towards Smart and Multifunctional Ceramics

Researchers are already looking beyond simple structural ceramic printing, working on composites that incorporate additional functionalities. The integration of conductive elements, piezoelectric properties, or even self-healing capabilities represents the next frontier. 🔮 Multi-material printing will enable the creation of components with ceramic, metallic, and polymeric zones in a single part, opening design possibilities that currently belong to the realm of speculation. We are witnessing only the first chapters of what promises to be a revolution in advanced materials.

Advanced ceramic 3D printing does not seek to replace traditional methods, but to create a new design space where complexity is free and customization is accessible

Conclusion: The Ceramic Renaissance of the Digital Era?

The advances by Prodways and HRL Laboratories in ceramic 3D printing represent much more than an incremental technical improvement. They symbolize the convergence between a millennial material and 21st-century manufacturing technologies, proving that even the most traditional materials have a place in the fourth industrial revolution. 🏭 The ability to create ceramic parts with impossible geometries, exceptional strength, and perfect adaptation to specific applications could redefine entire supply chains in high-value industries. After all, in a world that increasingly values customization and efficiency, having a material that combines the durability of ceramics with the flexibility of digital design sounds like the perfect recipe for industrial success. 😄