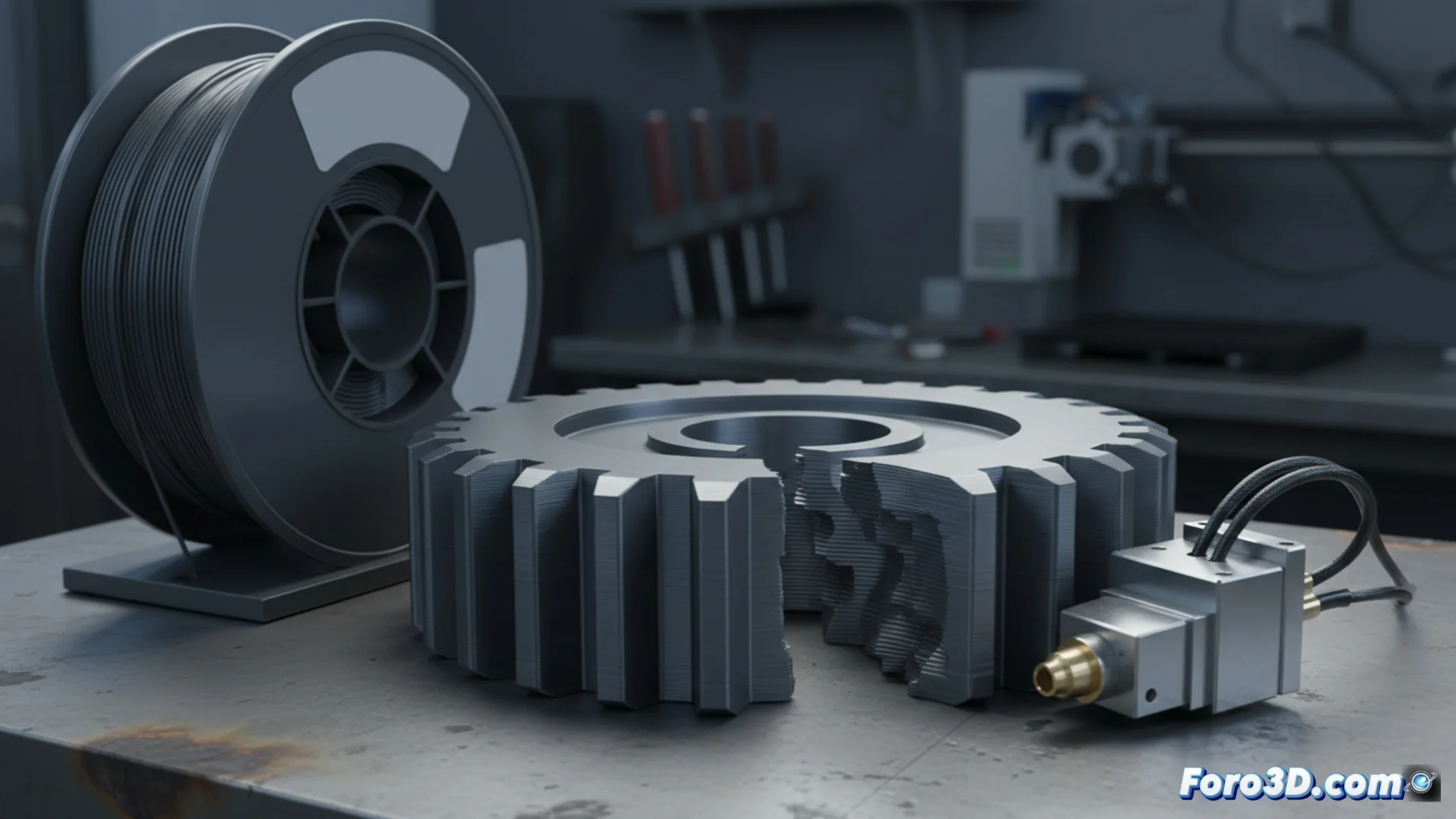

Pro PCTG: the industrial filament that balances robustness and printability

Industrial additive manufacturing needs technical materials that offer both solid mechanical properties and great printability. Pro PCTG emerges as a solution that meets these requirements, aimed at applications where durability and impact absorption capacity matter. This enhanced copolyester takes the best of PETG, such as its good layer adhesion and dimensional stability, but incorporates notably greater toughness. This enables the creation of functional prototypes, tools for direct use, and parts that withstand mechanical loads without breaking easily. 🛠️

Technical properties and key benefits

This material is processed at temperatures close to those of conventional PETG, allowing it to be adopted in many desktop 3D printers without changing the hardware. It shows a lower propensity to absorb environmental moisture compared to other technical filaments, making storage easier and providing uniformity to results. Its ability to resist chemicals like oils, greases, and certain solvents expands its use in factory environments. The final parts have a smooth surface and a finish that can be sanded and painted without issues.

Practical advantages of Pro PCTG:- It prints in a temperature range similar to common PETG, facilitating the transition.

- Absorbs less moisture, simplifying storage and improving print consistency.

- Resists exposure to oils, greases, and various solvents, suitable for industrial environments.

A material that promises to be tough and, unlike certain forum comments, does not crack at the first sign of stress.

Uses in demanding industries

This filament is suitable for producing protective covers, gears, fixtures, and components for the automotive or electronics sector. Its balance between rigidity and ability to cushion impacts makes it perfect for parts that experience intermittent mechanical stress. Areas such as engineering, medical equipment manufacturing, or consumer goods design are beginning to choose Pro PCTG when they need a plastic stronger than standard PLA or ABS, but without the processing difficulty presented by materials like unmixed polycarbonate.

Main sectors and applications:- Automotive and electronics for structural components and housings.

- Engineering for functional prototypes and end-use tools.

- Medical devices and consumer goods that require durability.

A material that makes a difference

Pro PCTG is consolidating as a serious option for those seeking robustness without complications. By inheriting PETG's manageability and adding much superior impact resistance, it fills a gap in the professional 3D printing filament market. It represents a step forward in manufacturing parts that must last and perform in demanding conditions, offering a more accessible path than high-engineering materials. 🚀