Precision Additive: Innovation in 3D Printing with Magnesium

A company called Precision Additive is making waves in the world of additive manufacturing. It's a U.S. startup betting on magnesium, a lightweight and difficult-to-work-with metal, to revolutionize 3D printing in the defense and aerospace sectors. The key? Their own system that promises to print parts with air certification quality directly from the machine. And no, you don't need to be a metallurgy expert to understand its potential! 🛠️

A Proprietary Technology that Avoids Past Mistakes

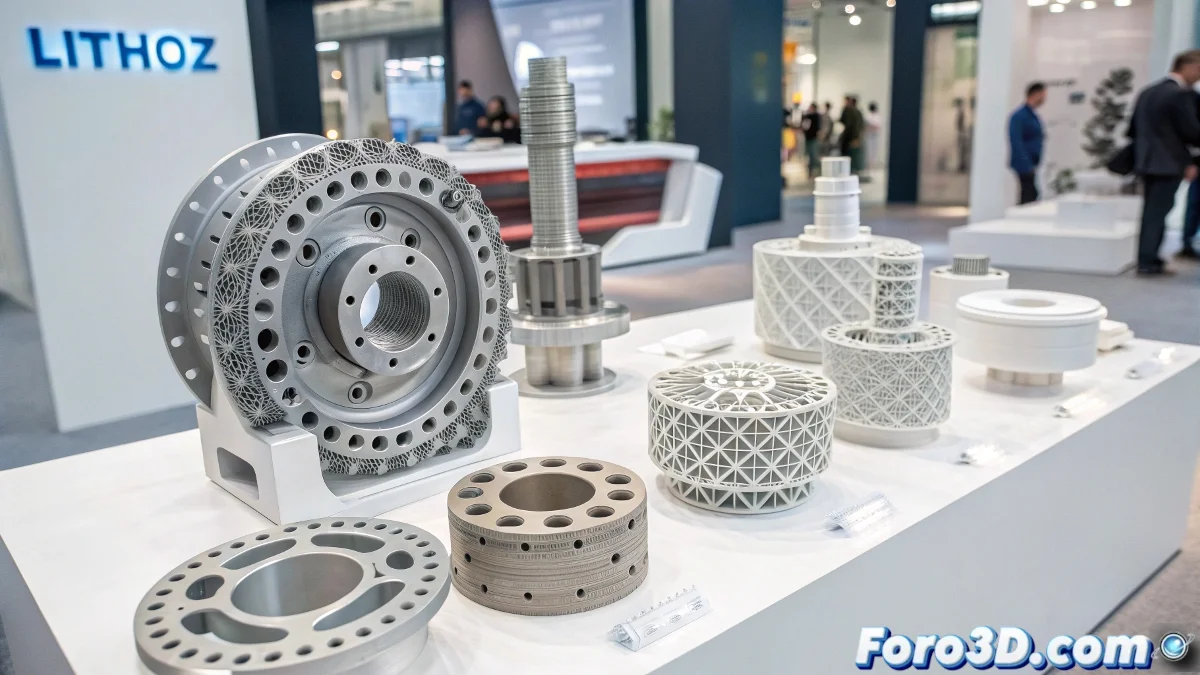

CEO Bala Anand Jeldi, known for building the world's largest SLS printer over a decade ago, now leads this new venture. His system, called SSLM (Selective Stepped Laser Melting), improves common issues with powder bed fusion: less porosity, fewer splatters, and greater material stability during printing. In short, parts ready to fly without going through a thousand validations.

Magnesium: Lightweight, Strong, and (Mis)understood

CTO Daniel Braley, former Boeing employee, is clear that magnesium has a bad reputation: many engineers believe it's explosive by default. But the reality is that it only poses a risk in powder or vapor form. As a solid piece, it's stable, lighter than aluminum, and excellent for absorbing vibrations, making it ideal for helicopters, drones, and even premium automotive components.

Applications from Space to Medicine

In the 3D environment, this type of advancement isn't limited to aerospace. In software like Siemens NX or SolidWorks, complex geometries that this new system can print can be modeled, and programs like Magics or Netfabb would be key in pre-processing. Additionally, printed magnesium could be used in biodegradable implants or even future batteries.

A Race Against Time... and China

The geopolitical background is no small matter. China controls over 90% of the world's magnesium supply, turning this metal into a national security issue for the U.S. Precision Additive not only wants to print parts but also explores ways to extract magnesium locally, for example, from U.S. dolomite. The goal: reindustrialize the supply chain of critical materials.

From 3 employees to 50, and still without showing the machine. The team went from a handful of people to a company that already has orders for more than 25 machines running non-stop, and that's without having shown the full system to the public. So for now, the rest of us have to imagine what the printer that promises to change the game looks like. Who would have thought that something as volatile as magnesium would be the most stable bet in the sector! 🌟

With this innovation, Precision Additive is marking a before and after in 3D printing. And remember, if something doesn't go as expected, you can always blame the technology! 😉