Excellence in Engineering Plastics

POM Acetal represents the pinnacle of technical materials for 3D printing, offering exceptional mechanical properties that have made it an industrial standard for precision components. Commercially known as Delrin, this engineering thermoplastic combines outstanding rigidity with a low coefficient of friction and nearly perfect dimensional stability. Its ability to maintain tight tolerances under various environmental conditions makes it invaluable for applications where mechanical performance is prioritized over any other consideration.

What sets POM Acetal apart is its unique combination of properties that few materials can match. Its excellent fatigue resistance allows components to withstand millions of load cycles without failure, while its low moisture absorption ensures that dimensions remain constant regardless of environmental conditions. These characteristics, combined with its exceptional chemical resistance, explain why it has been the material of choice for decades in industries such as automotive, medical, and consumer durables.

Outstanding Technical Properties

- Excellent wear resistance and low surface friction

- Exceptional dimensional stability with minimal hygroscopicity

- High rigidity and fatigue resistance in dynamic applications

- Superior chemical resistance to solvents and fuels

The Challenge of Mastering an Elite Material

Printing with POM Acetal requires specialized equipment and refined technique. This material demands printing temperatures between 210°C and 230°C, but its tendency to suffer thermal degradation from overheating makes precise temperature control essential. The heated bed must be maintained between 100°C and 120°C, and an enclosed chamber is practically mandatory to prevent thermal stress cracking during cooling. Bed adhesion represents another significant challenge, requiring specialized surfaces like glass with PVA or high-temperature PEI.

POM Acetal rewards investment in knowledge and equipment with unmatched mechanical capabilities

A critical consideration is the material's tendency to suffer significant warping if environmental conditions are not strictly controlled. Professional users employ enclosed chambers with ambient temperature control and perform slow prints to minimize internal stresses. Precise calibration of the nozzle-to-bed distance is crucial, as excessive separation can result in poor adhesion, while insufficient separation can cause over-extrusion in the first layer.

Applications Where POM is Indispensable

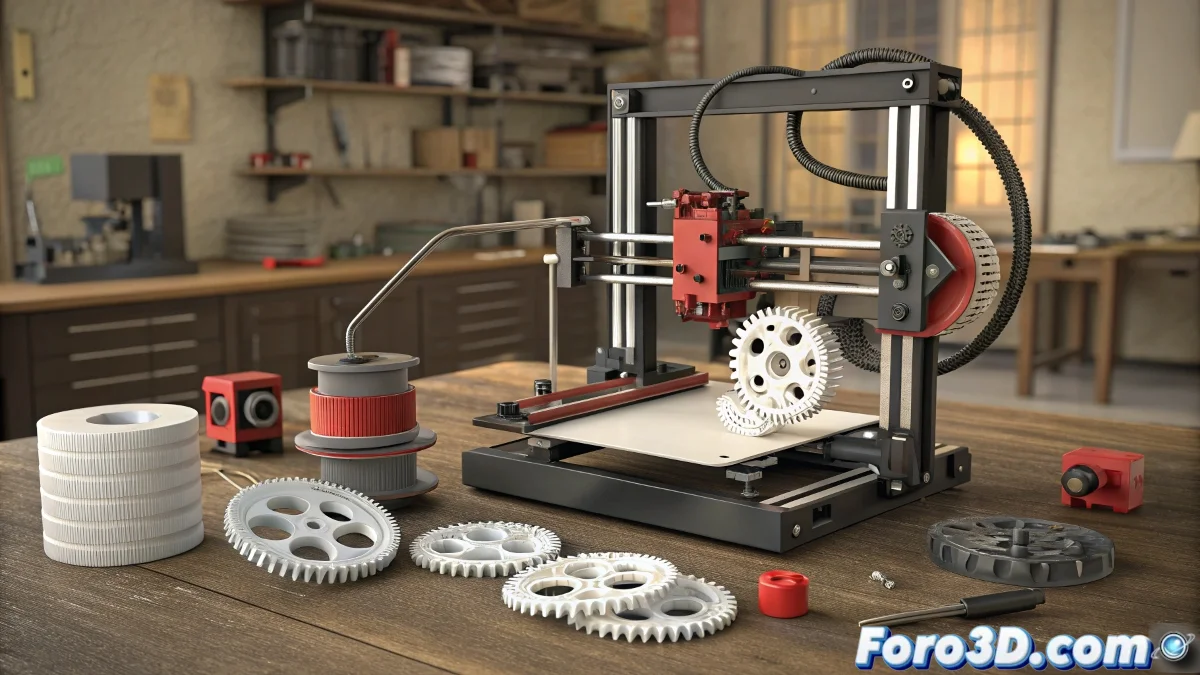

- High-durability precision gears and mechanisms

- Components for valves and hydraulic systems

- Linear guides and sliding elements

- Medical devices requiring sterilization

POM Acetal's ability to produce parts with tight tolerances and excellent mechanical properties keeps it as a reference material in demanding technical applications. Although it has a steep learning curve and requires investment in appropriate equipment, the performance it offers more than justifies the effort for projects where reliability and durability are critical. The possibility of creating components that rival those produced by traditional manufacturing methods positions this material in the elite of professional 3D printing filaments. ⚙️

Working with POM Acetal is like taming a mechanical bull: it requires patience, proper equipment, and respect for its peculiarities, but once mastered, there is no better steed for demanding technical races. 🐂

You can see this product and similar ones in the : store