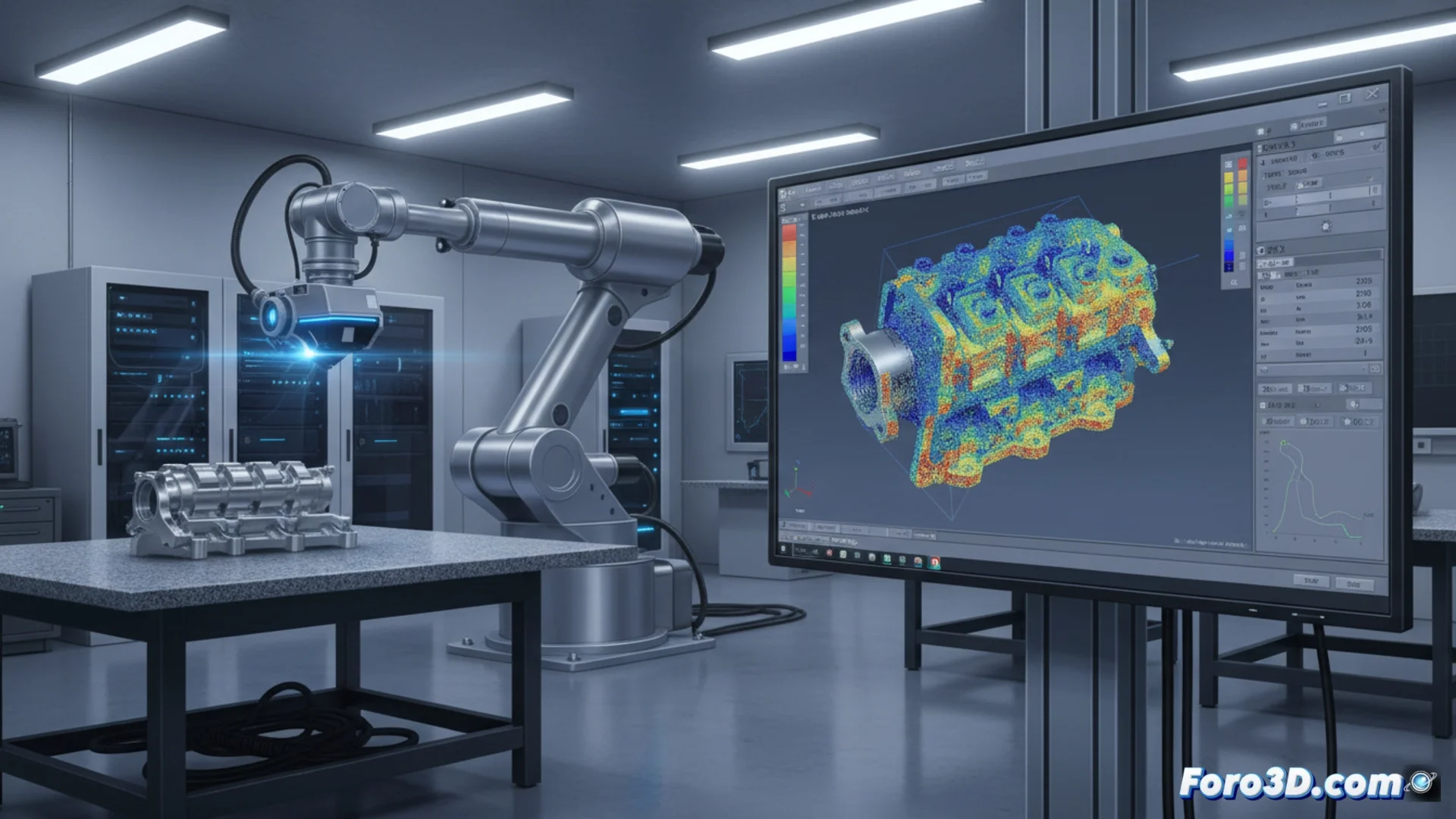

PolyWorks Uses AI to Analyze 3D Point Clouds

In the field of digital metrology, PolyWorks positions itself as an advanced solution for processing information captured through three-dimensional scanning. Its core uses artificial intelligence algorithms that examine point clouds to autonomously recognize patterns and shapes, laying the foundation for a more agile inspection workflow. 🔍

Intelligent Geometry Recognition

The capability of the integrated AI lies in discerning fundamental geometric elements within the apparent chaos of a point cloud. It not only locates these features but also proceeds to divide the data into logical sectors, organizing the information for subsequent analysis stages.

Key functions of automatic recognition:- Identify flat surfaces, cylindrical bodies, and spheres instantly.

- Separate different regions of the scanned part for individualized examination.

- Prepare the segmented data for the critical comparison phase with the theoretical model.

Automation in segmentation is the first step to turning raw data into actionable information for inspection.

Comparison and Visualization of Discrepancies

After aligning the actual scan with the reference CAD model, the software performs a meticulous comparison. It calculates the distances between the physical and digital geometry, representing the result in a color map overlaid on the 3D view. This intuitive visualization allows the operator to perceive at a glance the areas that do not meet the established tolerances. 📊

Advantages of the automated comparison process:- Significantly reduce the time needed to inspect a part.

- Precisely highlight minimal deviations, even just a few microns.

- Streamline the entire quality control process, from scanning to the final report.

Precision in Every Detail

The system is designed not to overlook any discrepancy. Even if a manufactured part may resemble its original design greatly, the algorithm remains tireless, detecting and reporting the slightest variations. This level of automated scrutiny ensures that quality control is thorough, consistent, and much less prone to human error, establishing PolyWorks as a powerful tool in high-demand manufacturing and engineering environments. ✅