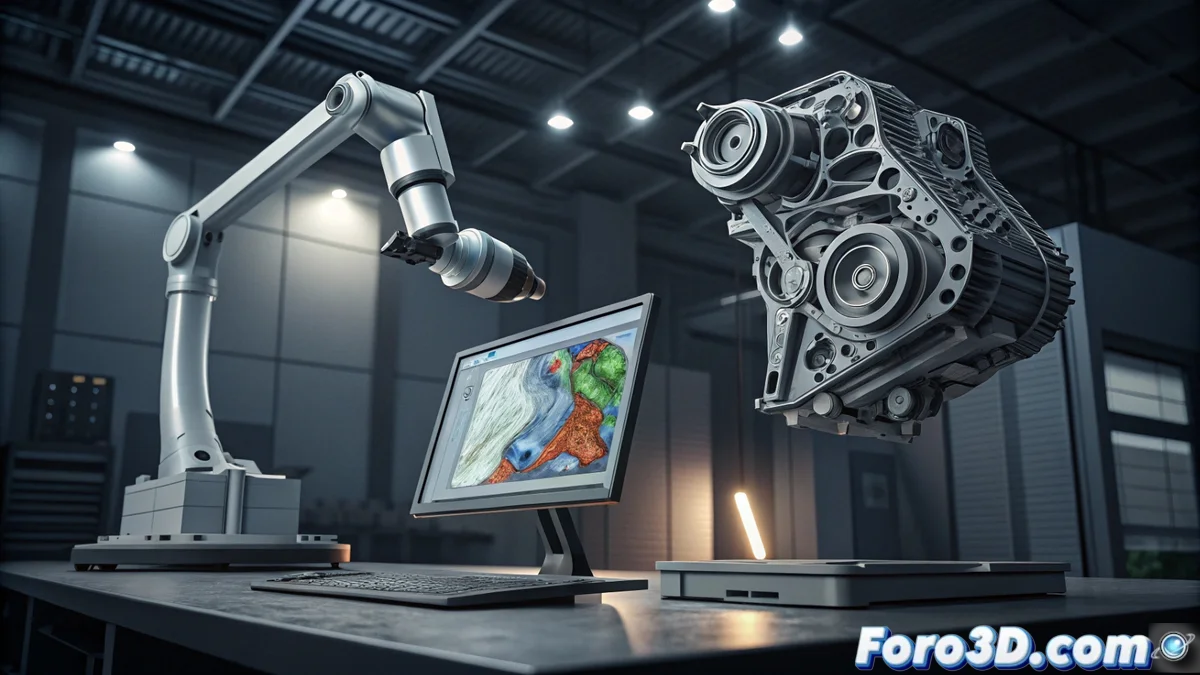

PolyWorks: the suite for 3D inspection and measurement

In the field of manufacturing and quality control, validating that a physical part matches its digital design is crucial. PolyWorks emerges as a comprehensive suite of applications dedicated to inspecting, measuring, and analyzing objects in three dimensions. Its core functions by comparing 3D scan data from a real component with its reference CAD model, ensuring compliance with defined tolerances. 🧐

Key industrial applications

This tool is essential in sectors where millimeter precision is non-negotiable. Automotive, aerospace, and medical device manufacturing companies use it to ensure that every component, from an engine block to an orthopedic implant, fits as planned. Additionally, it allows digitizing objects without existing technical documentation, a process known as reverse engineering, to then reproduce or redesign them.

Main uses in industry:- Verify that manufactured parts are within allowed tolerances.

- Detect deviations and generate detailed technical reports to audit production.

- Digitize physical objects (reverse engineering) to create 3D models and drawings.

It is preferable for the software to detect a failure in the part rather than an unsatisfied customer.

Operation and main tools

PolyWorks processes information captured by devices such as laser scanners, optical scanners, or coordinate measuring arms. It works with point clouds and polygonal meshes, offering a set of utilities to manipulate and evaluate this 3D data effectively.

Essential tools it includes:- Algorithms to precisely align and register the scan with the theoretical CAD model.

- Functions to measure distances, diameters, planes, and other complex geometries.

- Color map generators that graphically visualize deviations between the real part and the ideal design.

Impact on decision-making

The ability to visualize deviations intuitively through colors allows engineers and quality managers to make informed and quick decisions about the production line. Identifying a problem in time avoids costly rework, delays, and, most importantly, ensures the delivery of a final product that meets the highest standards. This suite establishes itself as an indispensable pillar for manufacturing with accuracy and confidence. ✅