The Structural Evolution of PLA

PLA with glass fiber represents a significant leap in the mechanical capabilities of PLA-based materials, offering structural properties that compete with more advanced engineering filaments. This composite material incorporates short glass fibers into the PLA matrix, creating a synergy where the ease of printing of the base material combines with the rigidity and thermal resistance of the reinforcement. The result is a filament that maintains PLA's accessibility while dramatically expanding its range of applications.

What makes this material special is its ability to improve multiple properties simultaneously. The glass fibers not only increase rigidity and tensile strength but also enhance thermal stability and reduce the coefficient of thermal expansion. This translates into parts that maintain their shape and dimensions under conditions that would cause standard PLA to deform or soften, opening possibilities for more demanding technical applications.

Significant Technical Improvements

- Rigidity up to 80% higher than standard PLA

- Improved thermal stability up to 15-20°C higher than conventional PLA

- Significant reduction in warping deformation

- Greater resistance to fatigue and creep under constant load

The Challenge of Controlled Abrasiveness

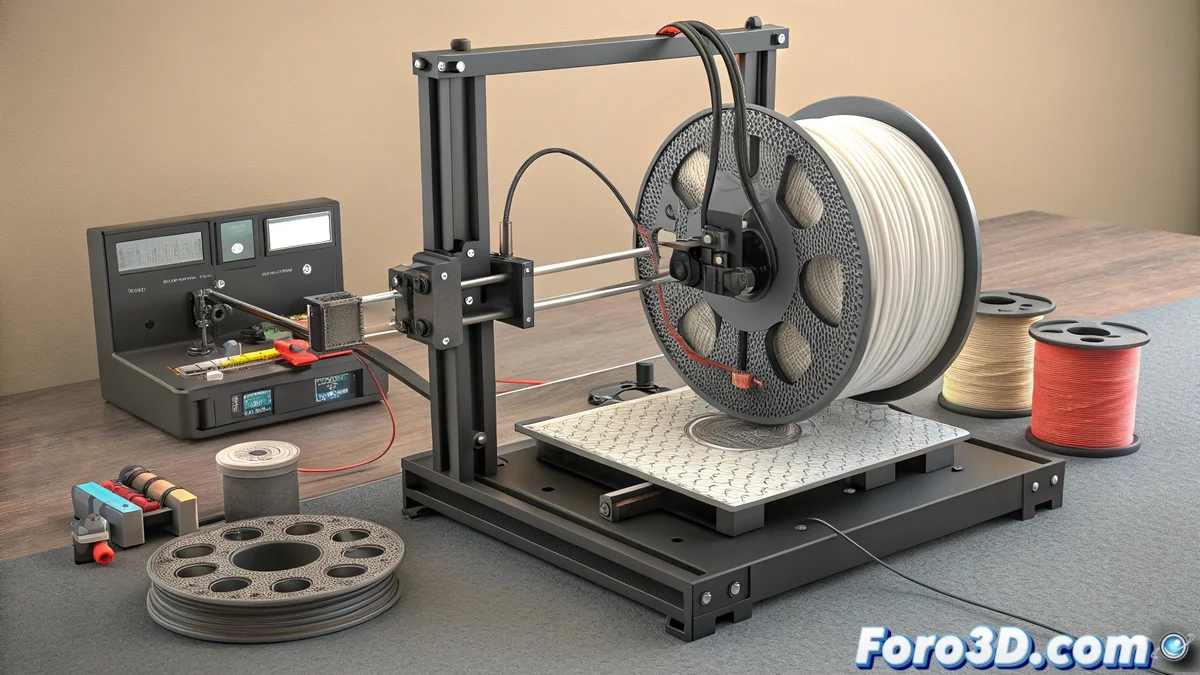

Working with glass fiber reinforced PLA requires preparation for the material's abrasive nature. The glass fibers, although less abrasive than carbon fibers, still wear out conventional brass nozzles. The use of hardened steel or tungsten carbide nozzles is highly recommended, especially for extensive projects. The printing temperature generally ranges between 205°C and 225°C, slightly higher than standard PLA to ensure proper flow of the composite material.

PLA with glass fiber offers engineering capabilities with PLA's simplicity

A notable advantage of this material is its exceptionally stable dimensional behavior. While conventional PLA can suffer significant deformations under prolonged load or high temperatures, the glass fiber reinforced version maintains its structural integrity under more demanding conditions. This characteristic makes it ideal for production fixtures, custom tools, and structural components that must withstand moderate mechanical stresses.

Advanced Technical Applications

- Tools and production fixtures for industrial environments

- Structural components for drones and robots

- Functional prototypes requiring rigidity and stability

- Medical and orthopedic devices that need durability

The versatility of PLA with glass fiber has found an important niche in applications where the perfect balance between technical performance and ease of processing is required. For engineers, product designers, and manufacturers who need to create functional parts without the complexity of more advanced materials, this composite represents an elegant and effective solution. The ability to produce reliable structural components with standard equipment democratizes access to capabilities that previously required significant investments in specialized equipment. 🏗️

Using PLA with glass fiber is like giving your prints a steel skeleton: on the outside it's still the PLA you know, but inside it has the strength to withstand challenges that would make its conventional siblings tremble. 💪

You can see this product and similar ones in the: store