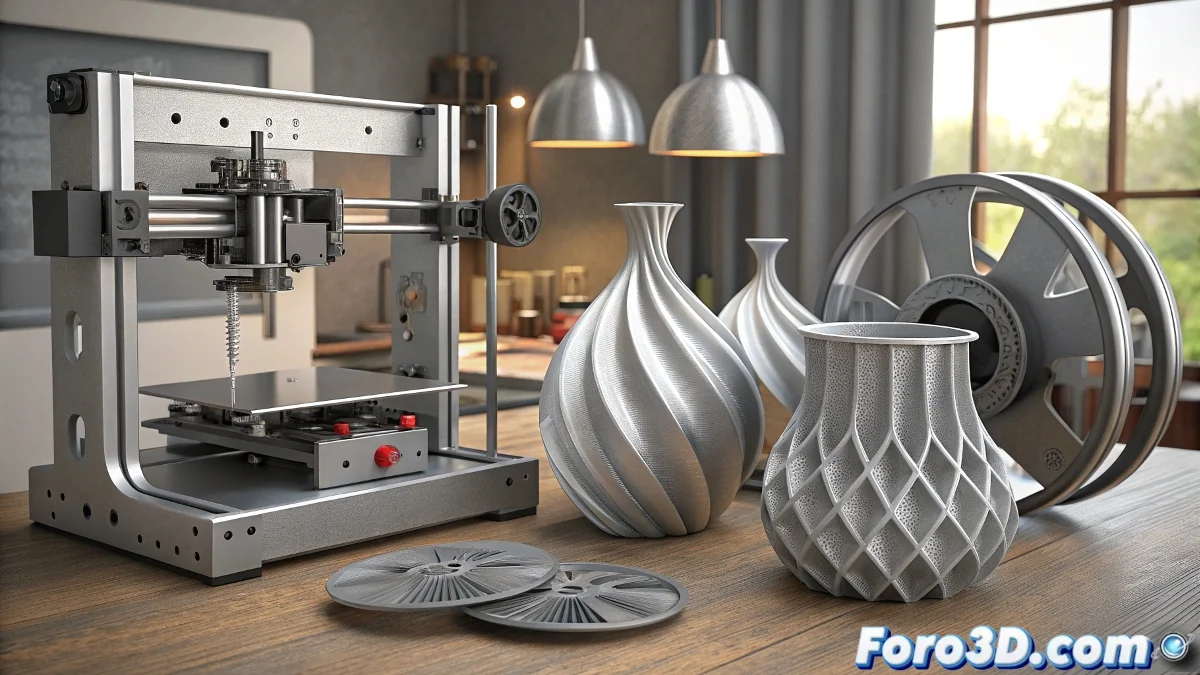

The Revolution of Lightweight Metal in 3D Printing

PLA with aluminum particles represents a significant advancement in metallic composite materials, offering the industrial appearance of aluminum with the accessibility of PLA. This innovative filament incorporates microscopic aluminum particles within the polymer matrix, creating parts that not only look like metal but also inherit some of aluminum's most valuable properties, such as its characteristic lightness and thermal dissipation capacity. The result is a material that bridges the gap between plastics and metals in applications where weight and aesthetics are crucial.

What distinguishes this material is its unique balance between lightweight and robust metallic appearance. Unlike other metallic composites that can be excessively heavy, aluminum PLA maintains a manageable density while providing that highly valued industrial look in product design and technical prototyping. Its surface features a matte silver finish reminiscent of anodized aluminum, with the ability to reflect light subtly yet distinctively.

Enhanced Technical Properties

- Lightweight compared to other metallic composites

- Better thermal dissipation than standard PLA

- Industrial silver finish with moderate reflectivity

- Slightly higher rigidity than conventional PLA

The Art of Printing with Aluminum

Working with aluminum PLA requires considering its moderately abrasive nature. The metallic particles, although softer than those of bronze or copper, still recommend the use of hardened steel nozzles for extensive projects. The optimal printing temperature is between 195°C and 215°C, with speeds of 40-60 mm/s that allow consistent extrusion. Cooling at 50-70% usually produces the best results, balancing layer adhesion with fine detail definition.

Aluminum PLA offers the premium industrial look without the complexity of pure metals

A significant advantage of this material is its exceptional response to mechanical post-processing. Parts can be sanded to achieve different degrees of shine, from a satin finish to an almost mirror polish. Additionally, it responds well to drilling and threading, allowing integration with other metallic components in mixed assemblies. This versatility makes it ideal for functional prototypes that must coexist with metal parts in final products.

Technical and Aesthetic Applications

- Product prototypes with industrial appearance

- Components for electronics requiring thermal dissipation

- Decorative elements with technological and modern style

- Tools and fixtures with professional appearance

The ability of aluminum PLA to combine lightness, industrial aesthetics, and certain metallic properties has positioned it as a favorite material for applications where technical image is as important as functionality. From electronic device housings to model automotive components, this material offers that perfect balance between practical performance and professional visual presence. The possibility of creating parts that look machined from aluminum using standard equipment represents a democratizing advancement in the world of prototyping and digital manufacturing. 🔧

Printing with aluminum PLA is like having a miniature machining workshop: you produce parts that look milled from metal, without the chips or characteristic noise, just the satisfaction of seeing plastic transformed into apparent aluminum. ⚙️

You can see this product and similar ones in the : store