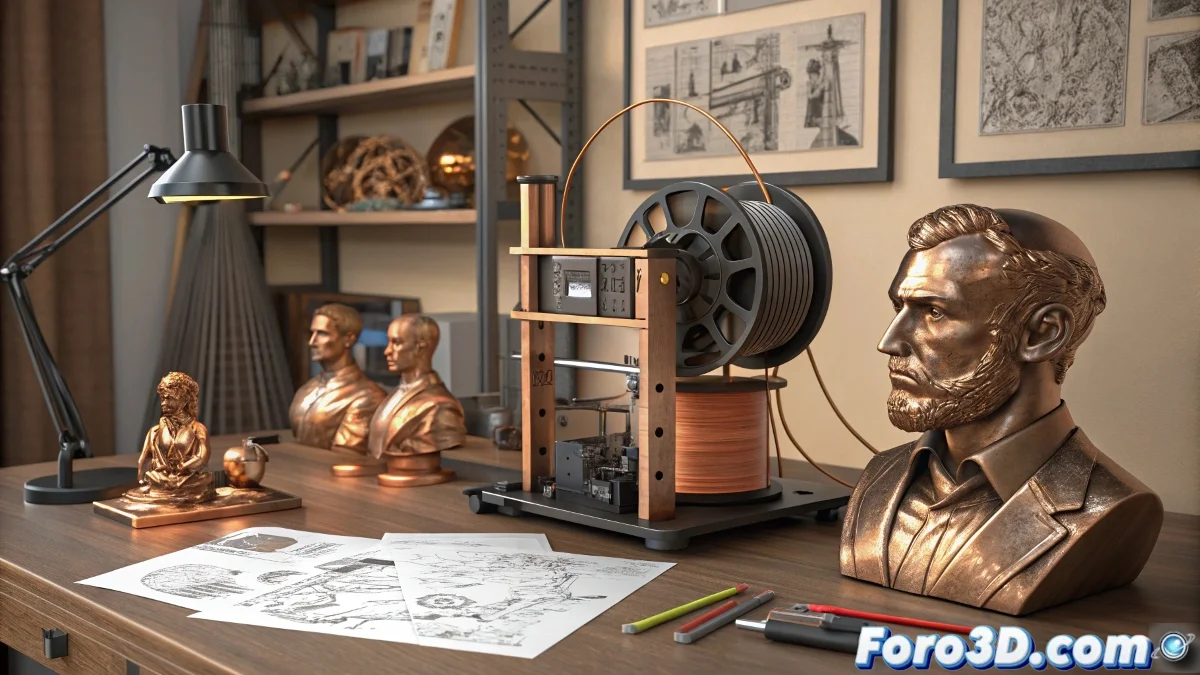

When Plastic Dresses in Metal

Metal PLA represents the perfect fusion between accessibility and luxury in the world of 3D printing, allowing to create parts with the appearance, weight, and feel of real metals using standard equipment. This composite material incorporates a high percentage of metallic particles - generally bronze, copper, brass, or stainless steel - in a PLA matrix, resulting in objects that deceive the senses and challenge expectations about what can be achieved with home 3D printing.

The magic of this material lies in its ability to be treated like metal after printing. Finished parts can be sanded, polished, and even oxidized through controlled chemical processes, achieving finishes that rival traditional casting. The significantly greater weight compared to standard PLA contributes to the sensation of quality and permanence, while the surface develops a natural patina over time that adds character and authenticity.

Unique Characteristics of Metal PLA

- Significantly greater density and weight than standard PLA

- Ability to develop natural patina over time

- Compatibility with polishing and metallic finishing techniques

- Surface texture that perfectly simulates cast metal

The Art of Printing with Metallic Particles

Working with Metal PLA requires specific technical adaptations due to its abrasive composition. The metallic particles act as micromaterial wear on the extrusion components, making it essential to use hardened steel or tungsten carbide nozzles. The printing temperature generally ranges between 195°C and 220°C, although some manufacturers recommend temperatures at the upper end to improve the flow of the metal-loaded material.

Metal PLA democratizes the creation of luxury-looking objects using accessible technology

One of the most fascinating aspects is the material's response to different post-processing techniques. Parts can be progressively sanded to achieve a mirror shine, treated with acids to create controlled aging effects, or painted with chemical patinas that enhance surface details. The final result depends as much on printing skill as on mastery of finishing techniques traditionally reserved for jewelry making and metallurgy.

Luxury and Specialized Applications

- Custom jewelry and accessories with metallic appearance

- Components for high-end architectural models

- Sculptures and artworks with professional finish

- Product prototypes that mimic the final finish

The versatility of Metal PLA has found a special niche in applications where aesthetics and perception of quality are as important as functionality. From designers creating limited product lines to artists exploring new forms of expression, this material offers a bridge between digital manufacturing and traditional artisanal techniques. The ability to produce objects with metallic presence and weight using accessible equipment represents a significant advance in the democratization of high-quality manufacturing. 👑

Printing with Metal PLA is like being a digital alchemist: you transform metallic powder and plastic into objects that seem valuable, although your nozzle probably thinks gold would be less abrasive. ⚱️

You can see this product and similar ones in the: store