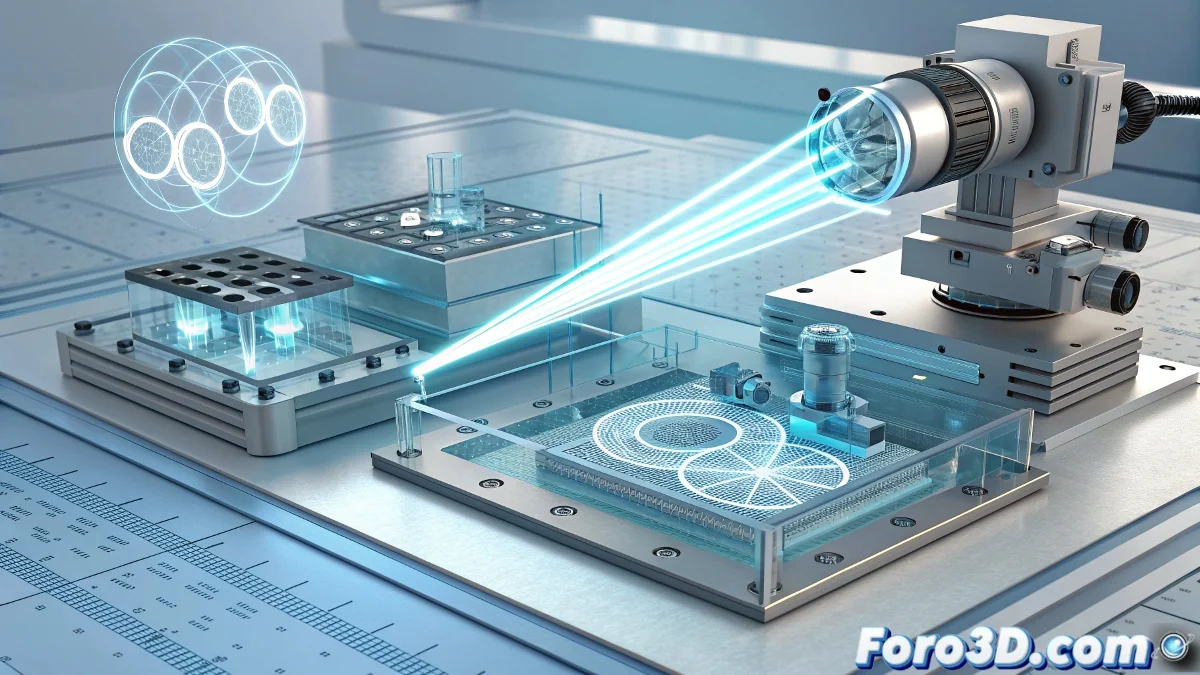

Photonic Systems and Additive Manufacturing Revolutionize 3D Printed Optics

The technological convergence between photonics and 3D printing is radically transforming the design and manufacturing of optical components. Integrated photonic systems with additive manufacturing enable the creation of structures that were previously impossible to produce using conventional methods 🔮.

Specialized Optical Materials for Additive Manufacturing

The key to this advancement lies in the development of optical resins and polymers with controlled light transmission properties. These specialized materials maintain their transparency and optical characteristics after the printing process, allowing precise control over refraction and diffraction.

Achievable Optical Properties:- Custom refractive indices according to the specific application

- Diffractive structures integrated directly into the design

- Chromatic dispersion control for multispectral applications

3D printing of optics represents a paradigm shift toward the digital manufacturing of photonic components with unlimited geometric complexity

Applications in Compact Devices and Integrated Systems

The unprecedented design flexibility allows integrating multiple optical functions into a single component. This functional integration is particularly valuable for wearable devices, medical systems, and telecommunications equipment where space is critical 📡.

Innovative Optical Components:- Custom aspherical lenses for aberration correction

- Light guides with complex geometries for efficient illumination

- Holographic elements printed directly onto optical surfaces

Democratization of Advanced Optical Technology

This approach significantly reduces entry barriers for the development of specialized optics, enabling researchers and small businesses to access capabilities that previously required massive investments. On-demand manufacturing of complex optical components accelerates innovation across multiple scientific and technological disciplines ✨.