When a Multinational Decides 3D Printing Is Better Than Selling You Spare Parts

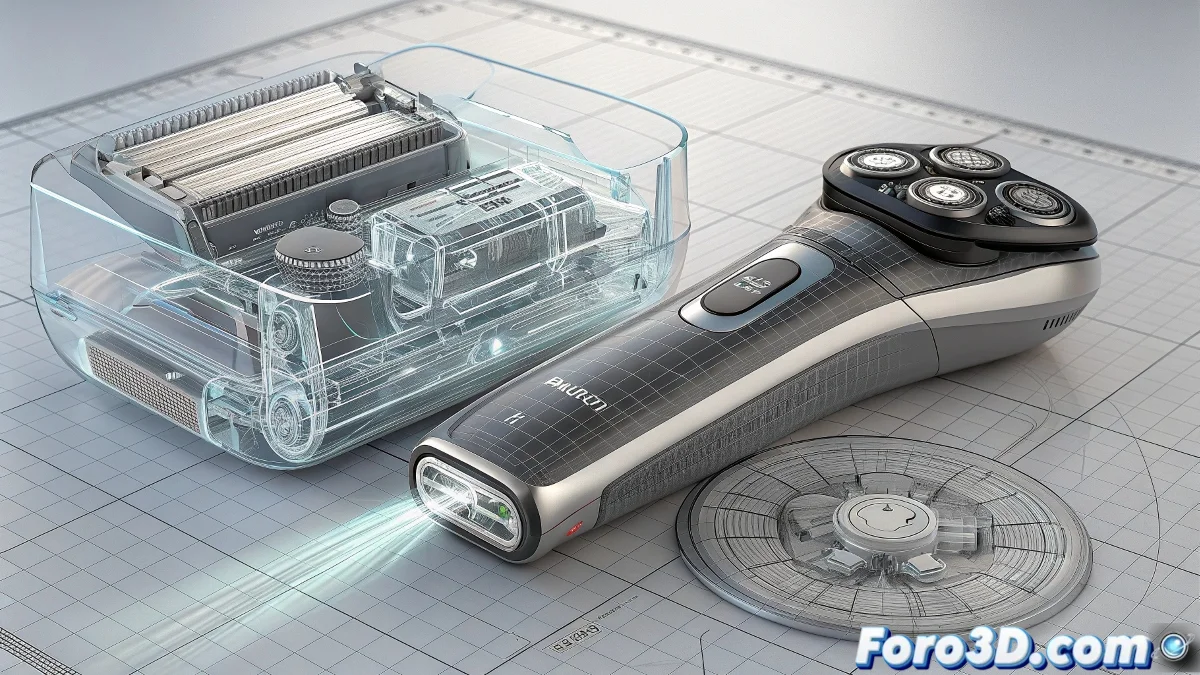

Philips is taking a revolutionary step in the relationship between manufacturers and consumers that could change forever how we approach appliance repairs. The collaboration with Prusa Research to offer 3D-printable parts for its shavers represents a strategic shift toward the circular economy. Instead of forcing users to buy official spare parts or discard functional products due to broken parts, Philips is empowering its customers with the means to self-repair.

This initiative demonstrates a mature understanding that customer loyalty in the 21st century is won with transparency and sustainability rather than planned obsolescence. By publishing 3D designs for parts like housings, supports, and fastening mechanisms, Philips not only reduces its environmental footprint but also builds a relationship of trust with increasingly eco-conscious consumers. Repair becomes an act of empowerment rather than a hassle. ♻️

In the circular economy, the best spare part is the one you can make yourself

The Repair Ecosystem They Are Building

The Philips-Prusa collaboration goes beyond simply publishing STL files. They are creating a complete framework for home repairs.

- Library of certified designs tested to ensure compatibility and safety

- Detailed printing guides with recommended settings and filament types

- Step-by-step assembly instructions that simplify the repair process

- Community support forums where users share experiences and improvements

The choice of Prusa Research as a partner is no coincidence: its open-source philosophy and extensive maker community ensure the project has the necessary ecosystem to thrive.

Impact Beyond Shavers

This movement could set a precedent for the entire appliance industry. The implications are profound.

- Reduction of electronic waste by extending product lifespan

- Empowerment of consumers to keep their devices functional

- Creation of local microeconomies around 3D printing services

- Competitive pressure on other brands to adopt similar models

If the model proves commercially viable, we could see other consumer electronics giants follow suit, fundamentally transforming our relationship with the products we buy.

The Challenges of 3D-Printed Repairs

Although the initiative is commendable, practical implementation presents significant obstacles that will require solutions.

Not all users have access to 3D printers or the skills to operate them effectively. Additionally, certain critical parts that require millimeter tolerances or specialized materials might still be better manufactured industrially. Success will depend on how well Philips and Prusa can balance accessibility with functionality. 🔧

And if this model works, we might soon be printing spare parts for our entire home... though we'll probably still need professional help for those parts that require more patience than technical skill 😉