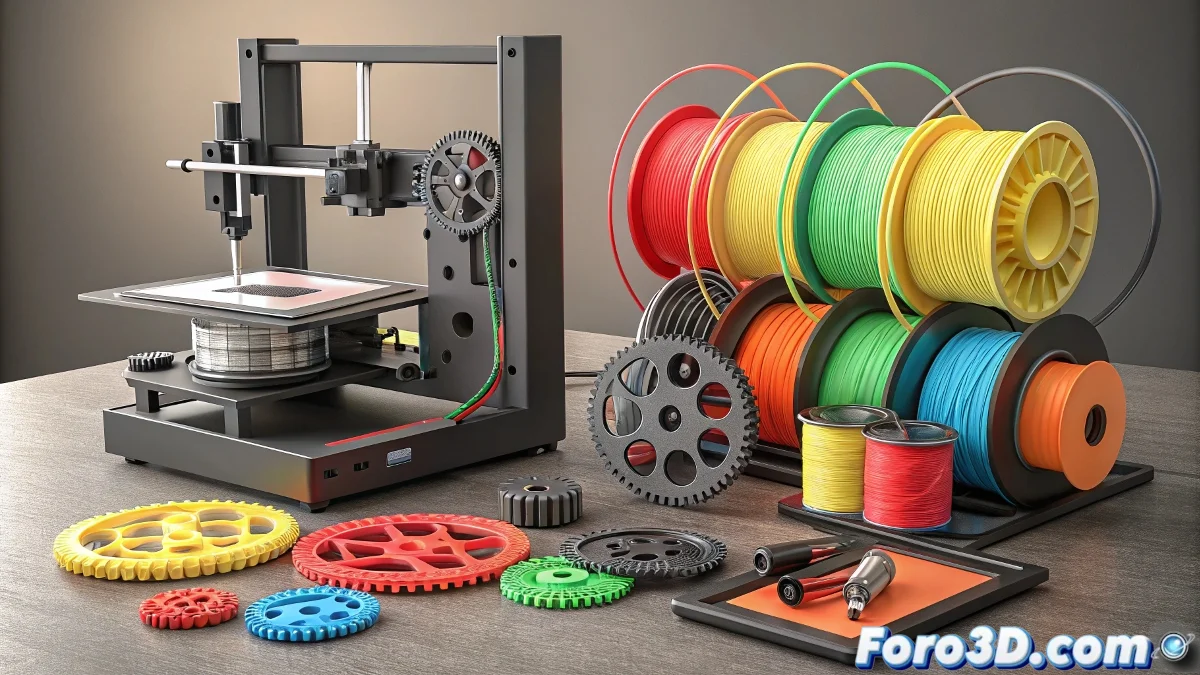

The Ideal Middle Ground in 3D Printing

PETG has emerged as one of the most versatile filaments in the 3D printing ecosystem, positioning itself as the preferred option for applications that require durability without sacrificing ease of printing. This copolymer, derived from PET commonly used in bottles, combines the best of two worlds: the accessibility of PLA and the robustness of ABS. Its popularity among technical users and professionals is not surprising when analyzing its balanced properties.

What truly distinguishes PETG is its ability to produce functional parts with moderate mechanical requirements. Unlike PLA, it does not become brittle over time, and compared to ABS, it does not emit strong odors during printing. Designers of mechanical parts and functional components find in this material a reliable ally for prototypes that must withstand a certain degree of mechanical and environmental stress.

Outstanding Technical Characteristics of PETG

- Excellent chemical resistance to oils, lubricants, and common solvents

- Natural transparency that allows creating high-quality semi-transparent parts

- Moderate flexibility that absorbs impacts better than traditional PLA

- Accessible printing temperature between 220°C and 250°C

Practical Advantages for the Printer

One of the greatest attractions of PETG lies in its predictable behavior during the printing process. Unlike ABS, which can be prone to warping and requires an enclosed heated bed, PETG prints satisfactorily with a bed between 70°C and 80°C. Its adhesion to surfaces like glass or PEI is notable, although users quickly learn that a little distance between the nozzle and the bed prevents over-adhesion.

PETG represents the natural evolution for those seeking to overcome the limitations of PLA without facing the complexity of ABS

In practical applications, PETG excels in components that require weather resistance and chemical resistance. From tool holders to electronics enclosures, this material maintains its properties in conditions where PLA would fail. Its ability to resist UV exposure better than many other filaments makes it ideal for outdoor applications, although it is not completely immune to prolonged solar degradation.

Ideal Applications for PETG

- Mechanical parts that require some flexibility and impact resistance

- Outdoor use components like supports, fasteners, and protectors

- Containers and devices that may come into contact with liquids or chemicals

- Transparent or semi-transparent parts for visual applications

The unique combination of properties of PETG makes it the filament of choice for those looking to transition from decorative prints to truly functional parts. Its balance between performance and ease of use explains why it has become a staple material in design workshops, prototyping labs, and advanced educational environments. ⚙️

And if you've ever wondered which filament to use when PLA is too weak but ABS is too complicated, you've just found the golden answer. ✨

You can see this product and similar ones in the : store