The Rolls Royce of 3D Printing Materials

PEI Ultem represents the pinnacle of the pyramid in 3D printing materials, offering exceptional properties that place it in the elite of engineering thermoplastics. Originally developed for high-performance aerospace and medical applications, this polyetherimide combines extraordinary thermal resistance with excellent mechanical and chemical properties. Its ability to maintain structural integrity up to 217°C and its UL94 V-0 self-extinguishing classification make it the material of choice where safety and performance are non-negotiable.

What sets Ultem apart is its unique combination of high-level properties. It not only withstands temperatures that would melt most filaments but also maintains its mechanical properties in extreme conditions, is resistant to gamma radiation, and offers exceptional dimensional stability. These characteristics explain why it has been the material of choice for critical applications in industries where failure is not an option, from aviation components to sterilizable medical devices.

Elite Technical Properties

- Continuous thermal resistance up to 217°C without deformation

- Self-extinguishing and UL94 V-0 classification

- Excellent chemical resistance to hydrocarbons and solvents

- Natural amber transparency with optical quality

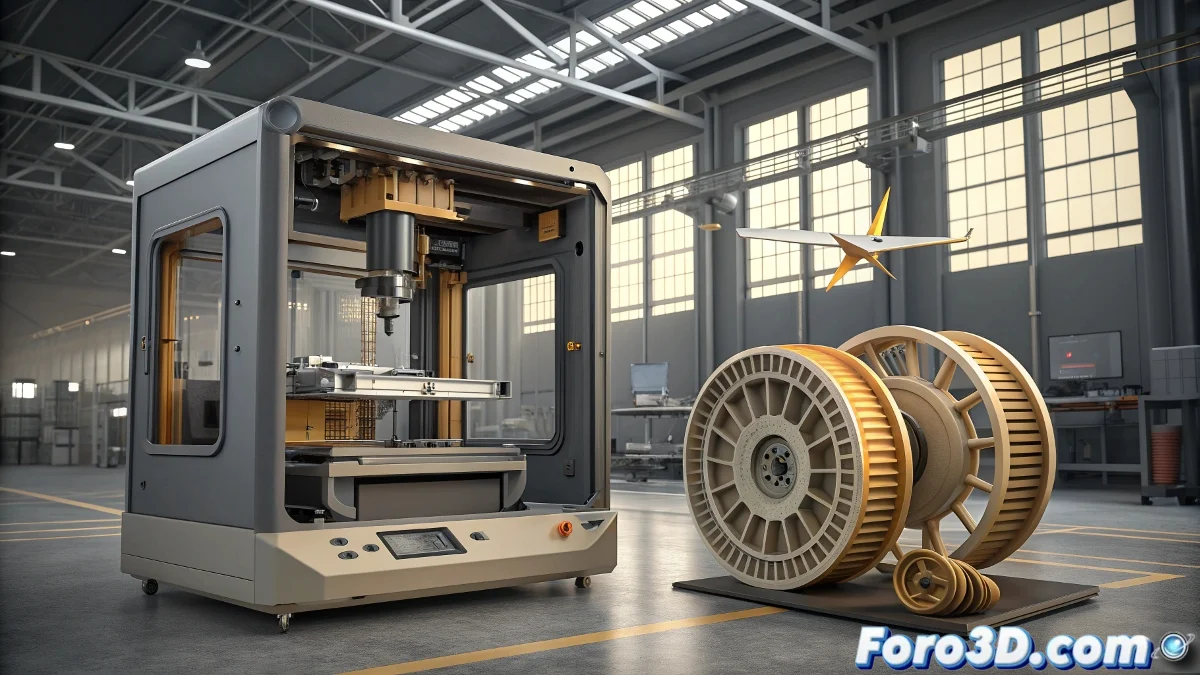

The Challenge of Printing with Aerospace Material

Working with PEI Ultem requires industrial equipment and controlled conditions. This material demands extremely high printing temperatures, generally between 350°C and 430°C, which limits its use to printers with hotends capable of operating consistently in this range. The heated bed must maintain between 160°C and 200°C, and a closed chamber with ambient temperature control is essential to prevent thermal stress cracking during the printing process.

Ultem sets the gold standard for applications where extreme performance is indispensable

Material preparation is critical for success with Ultem. Unlike other filaments, PEI requires thorough drying prior to printing, generally at 150°C for 4-6 hours, followed by printing from an active dry box. The hygroscopic nature of the material means that exposure to the environment for just a few hours can seriously compromise print quality. Professionals use specialized equipment to handle this material from storage to final printing.

High-Performance Applications

- Aerospace and aviation components

- Medical devices for autoclave sterilization

- Equipment for chemical and petrochemical industries

- High-temperature automotive components

The ability of PEI Ultem to operate in environments where other materials fail has established it as the preferred solution for mission-critical applications. From brackets in aircraft engines to supports for high-power electronic circuits, this material offers the level of reliability that fully justifies its premium cost and demanding technical requirements. The possibility of producing parts with aeronautical and medical certification through 3D printing represents a significant milestone in the evolution of industrial additive manufacturing. ✈️

Working with Ultem is like piloting a fighter jet: it requires specialized training, top-tier equipment, and a generous budget, but once in the air, there's no better machine for impossible missions. 🚀

You can see this product and similar ones in the: store