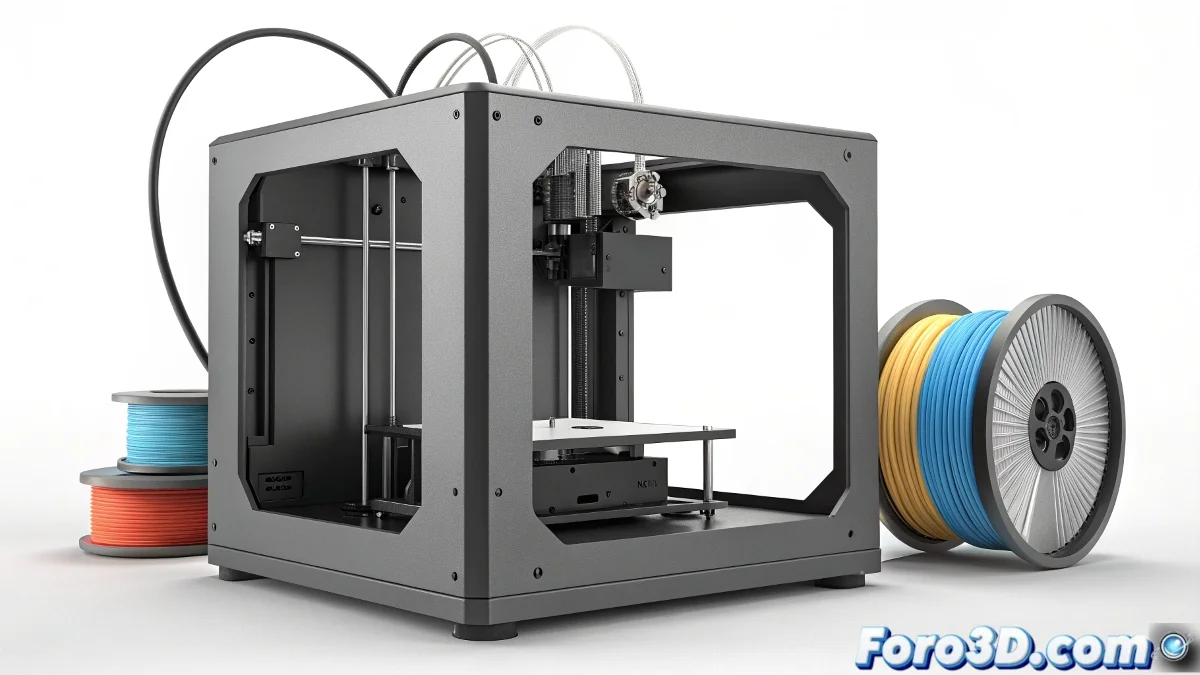

P2S: When 3D Printing Becomes Smart and Multifaceted

The 3D printer P2S is generating buzz in the maker community by integrating capabilities that previously required multiple devices or complex modifications. This unit not only masters mult filament printing with up to five different materials, but also incorporates an artificial intelligence system for real-time error detection, a 7-inch touch screen with an intuitive interface, and quick-swap nozzles that transform maintenance from a tedious task into a simple process. The P2S represents the convergence between accessibility and professional capabilities in 3D printing. 🖨️

Mult filament Without Complexity

What distinguishes the P2S is not simply its ability to print with multiple materials, but how it simplifies a traditionally complex process. While previous systems required extensive manual calibration and experimental adjustments, the P2S uses integrated flow and temperature sensors that automatically compensate for differences between materials. The optimized purge system minimizes filament waste during changes, and the zoned heated bed allows different temperatures depending on the material being printed in each area. This makes it possible to create parts with soluble supports, rigid-flexible combinations, or multicolor models without the steep learning curve of previous systems.

Innovative Technical Features

Every aspect of the P2S has been designed to solve specific problems that have plagued 3D printing users for years, from failure detection to ease of use.

Predictive Artificial Intelligence System

The integrated AI continuously analyzes the printing process through a high-resolution camera and vibration, temperature, and flow sensors. The system can detect incipient problems such as nozzle clogs, bed adhesion failure, or extrusion failures before they ruin a many-hour print. When it identifies a problem, it not only alerts the user, but also suggests specific solutions based on patterns learned from thousands of prints. Over time, the system adapts to the specific characteristics of each printer and user.

AI Capabilities:- early detection of print failures

- real-time first layer quality analysis

- recognition of clogs and under-extrusion

- suggestions for material-optimized parameters

Quick-Swap Nozzles and Purge System

The magnetic nozzle system allows changing between different sizes and materials in less than 30 seconds without tools. Each nozzle includes an RFID chip that automatically configures optimized temperature and flow parameters. The three-stage purge system ensures a clean transition between materials, with a dedicated purge chamber that collects the transition material for reuse. This is particularly valuable for composite materials that can clog nozzles or for changes between materials with very different temperatures.

The P2S doesn't just print with multiple materials; it makes the process as simple as changing colors on a 2D printer.

User Interface and Connectivity

The 7-inch touch screen features an interface that prioritizes relevant information according to context: it shows 3D visualizations of the model during preparation, real-time graphs of temperature and flow during printing, and intuitive alerts when problems are detected. Connectivity includes Wi-Fi 6, Ethernet, and USB-C, with a complementary mobile app that allows remote monitoring and control of prints. The integrated file system can store hundreds of models with 3D previews.

Interface Features:- 7-inch capacitive touch screen

- 3D visualization of models and toolpaths

- remote monitoring through mobile app

- internal storage with previews

Precision and Printing Capabilities

With a build volume of 300x300x350mm and the ability to reach speeds of 300mm/s without sacrificing quality, the P2S positions itself in the professional segment. The dual Z structure and Gates belts ensure consistent precision even in long prints. The high-flow hotend can process technical materials like Nylon CF, PC, and composites without issues. For users requiring maximum precision, high-resolution mode reduces speed to 60mm/s but offers layer details up to 0.05mm.

Technical Specifications:- build volume: 300x300x350mm

- maximum speed: 300mm/s

- layer resolution: 0.05-0.4mm

- maximum hotend temperature: 350°C

In the end, the P2S demonstrates that 3D printing is maturing from experimental technology to a reliable tool, though it will probably make your other printers feel a bit primitive in comparison. 🔧