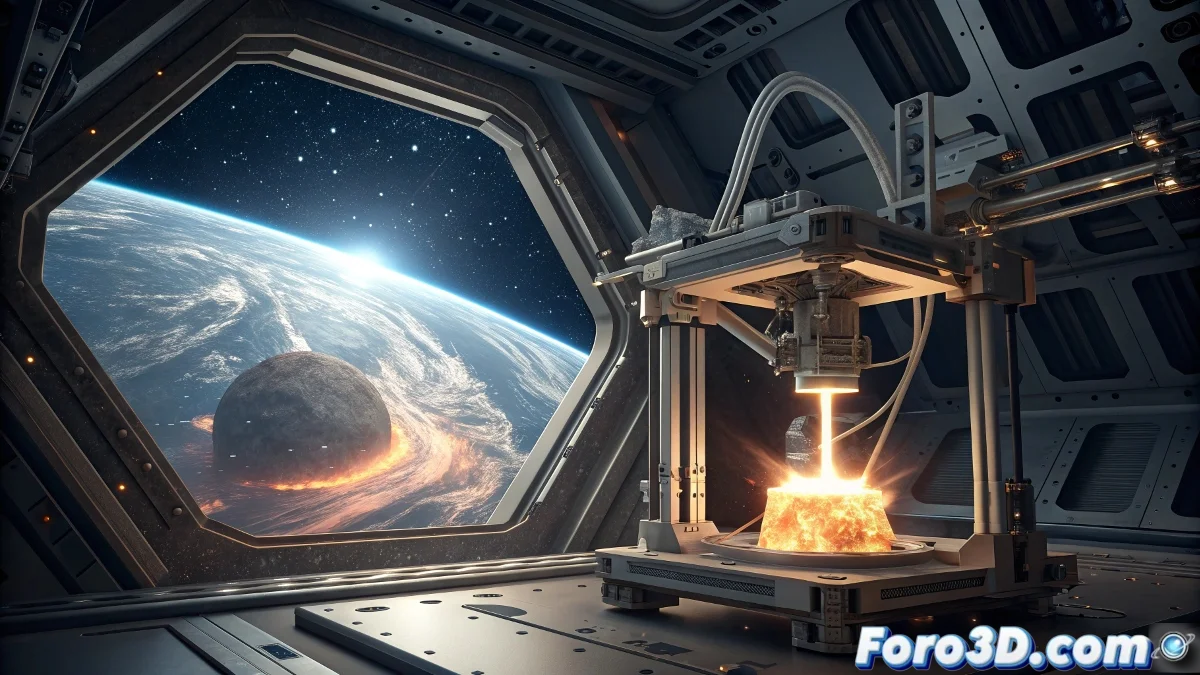

Orbital 3D Printing Transforms Space Construction with Sustainable Technologies

Additive manufacturing in space is completely redefining orbital construction paradigms, enabling the creation of complex structures directly in orbit without relying on Earth launches. This revolutionary technology employs specialized materials and 3D printing systems adapted to operate in microgravity conditions, producing everything from solar panels to habitational modules with unprecedented efficiency 🚀

Innovative Solutions for Orbital Waste Management

One of the most significant challenges facing this technology is its potential impact on space debris, but researchers have developed advanced mechanisms that turn this problem into an opportunity. Contemporary systems integrate containment technologies that capture all particles generated during manufacturing processes, while pioneering projects use existing space debris as valuable raw material.

Key Strategies Implemented:- Particle capture systems that prevent waste dispersion during printing

- Transformation of abandoned satellites and metal fragments into useful construction materials

- Active cleaning protocols that contribute to decontaminating Earth's orbit

We are witnessing the birth of a space circular economy where waste becomes valuable resources

Integrated Recycling Technologies in Orbit

The most advanced orbital 3D printers incorporate real-time recycling systems that process materials during the same manufacturing process. These self-sufficient machines can melt and reuse their own printing waste, in addition to processing materials from other space sources. Leading companies like Made In Space have perfected technologies that enable continuous reprocessing of materials, establishing nearly closed manufacturing cycles where material loss is drastically minimized.

Innovations in Orbital Recycling:- Reprocessing systems that melt and reuse printing waste immediately

- Technologies to process materials from various obsolete space objects

- Nearly closed manufacturing cycles that maximize resource efficiency

The Future of Sustainable Space Manufacturing

Orbital 3D printing represents a fundamental paradigm shift in how we approach construction in space, applying circular economy principles on a cosmic scale. Although questions arise about how we will manage failed prints that will inevitably float as technological ghosts, current solutions demonstrate a genuine commitment to space sustainability. This technology not only solves logistical problems but also lays the foundation for a permanent and responsible human presence in space 🌌